The denim industry leaves cotton behind. Levi’s and VirgoCoop the cottonized hemp

Denim production considers further investments on hemp to replace cotton. The cases of Levi’s hemp selvedge 501 jeans and Nimes’s Futura 75 variety in partnership with VirgoCoop

San Francisco: Levi Strauss & Co. to introduce plant-based, hemp selvedge, and circular 501® jeans

To celebrate the 150th anniversary of the Levi’s 501® jeans, Levi’s has introduced a collection of products that showcases the application of new ideas and technologies to their classic pieces, using a minimum of 97% materials derived from organic cotton, natural dyes and a plant-based patch with ink made from wood waste.

In 2019, Levi Strauss & Co. partnered with a Swedish textile recycling startup to introduce Levi’s WellThread x Outerknown, which featured a clothing collection made from cottonized hemp. Since then, Levi’s has expressed intentions to incorporate this use of hemp in their future clothing lines. One example is the Selvedge 501® made in a hemp-cotton blend, which is set to be released periodically throughout the year 2023.

Although cottonized hemp has not yet received official certification as a fabric, Levi’s has revealed their collaboration with different fashion industry associations to address this issue. This development provides optimism that cottonized hemp has the potential to be extensively embraced by the fashion industry in the foreseeable future.

Occitania, Nimes revives the industry using hemp variety Futura 75. The case of VirgoCoop

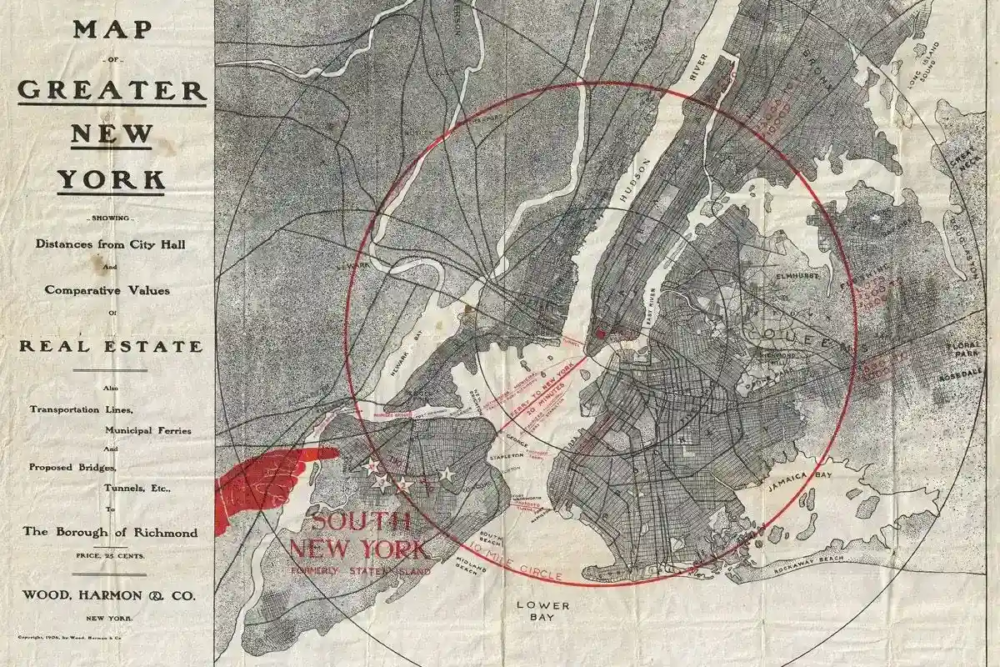

Occitania, a historically notable region in southern France, is currently witnessing a resurgence in the production of hemp textiles, particularly in the form of durable, long-fiber denim fabric used for jeans. In addition to the renowned wine region of Languedoc, Occitania was once famous for its extensive cultivation of commercial hemp, which supplied weaving workshops in the countryside.

The city of Nimes, located at the heart of Occitania, holds notoriety as the birthplace of denim. The iconic fabric known as Serge de Nimes, a sturdy twill weave made from hemp and dyed with indigo, was originally produced there. This material was used to create jeans and eventually gave rise to the term ‘denim’, which is now commonly associated with jeans fabric.

In the town of Castres, the weaving mill called Tissages d’Autan, established in the 1930s, is now partnered with VirgoCoop, a business management consulting firm in Cahors, France. Mathieu Ebbesen, co-founder and director of the Tissages d’Autan mill and president of VirgoCoop, is dedicated to coordinating the efforts of hemp growers, spinners, and weavers while prioritizing social equity and economic progress within the community.

The Futura 75 cultivar of hemp and cottonization as a solution

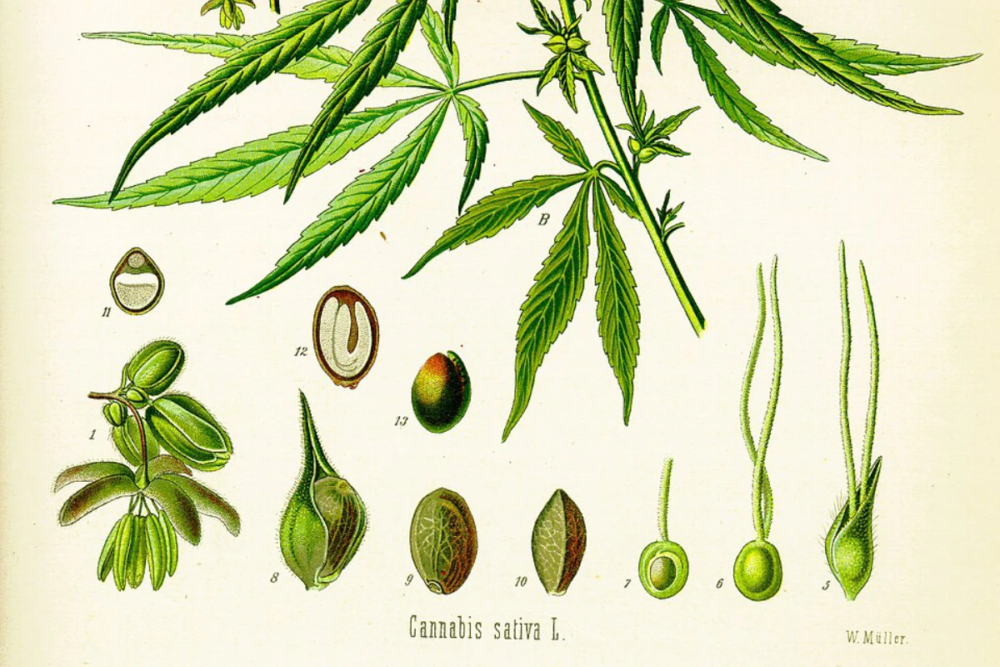

In 2018, the mill successfully produced great quantities of pure hemp yarn using the French cultivar Futura 75, which is approved by the European Union as an industrial hemp variety with a THC content below 0.3%. However, the quantity produced was insufficient for making jeans.

As a result, the mill resorted to importing Romanian hemp yarn to produce denim fabric. This strategic decision aimed to stimulate the market and justify investments in Occitania. The denim fabric was then supplied to a fashion company, which sold nearly 1 000 pairs of hemp jeans, marking a milestone in the growth of the local textile sector.

The Futura 75 hemp is good both for short winter season and the long summer season in Europe

The Futura 75 cultivar of hemp is well-suited for both the short winter season in northern Europe and the long summer season in southern Europe. It grows rapidly, reaching up to 4 meters tall by August when sown in spring. This cultivar yields high fiber production and its seeds can be harvested in the autumn if left to mature.

Ebbesen anticipates that within a decade, the challenges associated with preparing and spinning long hemp fibers will be overcome, resulting in larger volumes of high-quality hemp fiber available for the mill to work with. He acknowledges that processing long fiber hemp into jeans would make them very expensive. To avoid this, cottonization can serve as a solution.

Hemp is an eco-friendlier choice than cotton for denim production

Cottonized hemp is a fabric that results from a process aimed at softening hemp fibers to achieve a gentle, cotton-like texture. Through fiber technology, the structure of hemp is broken down and woven into a material that closely resembles traditional cotton. It utilizes pressure, alkaline water, and enzymes to release bast fibers from the bark of the plant.

The resulting cottonized fibers are shorter and softer, allowing them to be spun with standard cotton or wool-spinning equipment. Cottonization offers the advantage of faster spinning and enables blending hemp with other fibers in yarns, providing versatility and profitability for farmers and processors.

Hemp is recognized as a more sustainable alternative to cotton for various reasons. In terms of cultivation, hemp requires approximately four times less water compared to conventional cotton and utilizes roughly half the amount of land. It necessitates minimal fertilizer usage, fewer pesticides, and can even enrich the surrounding soil. Additionally, hemp yields a higher amount of fiber per hectare.

The process of cottonization of hemp

In conclusion, the production of cottonized hemp requires fewer resources while yielding a greater crop, making it a beneficial choice for both the planet and the fashion industry. Cotton production has long been burdened with drawbacks, such as high water consumption, pesticide requirements, and labor-intensive harvesting, which contributed to its expensive nature.

One of the appealing aspects of cotton is the ease of processing its fibers, which are naturally found within the seed pod. In contrast, hemp and flax fibers are obtained from the stem of the plant in the form of bast fibers.

These fibers, which provide the plant with rigidity, are primarily composed of cellulose, lignin, hemicellulose, and pectin, making them coarse and stiff. The primary goal of cottonization is to remove as much of these non-cellulosic components as possible, leaving behind most of all pure cellulose fibers. These fibers not only possess similar handleability to cotton fibers but also tend to be more durable.

Degumming hemp fibers with combined microwave energy

A study supported by the Louisiana Board of Regents and National Science Foundation and published in Industrial Crops and Products Volume 184 in September 2022 presents a new cost-effective method to degum hemp bast fibers at lower environmental impact.

The presence of gums, lignin and other non-cellulosic components in hemp fibers poses challenges for subsequent textile processes such as spinning, weaving, dyeing, and finishing. Therefore, degumming, which involves the removal of said components, is a critical step to effectively utilize these fibers.

Solely relying on biological treatments as a replacement for chemical treatments is insufficient to yield individual hemp fibers of desired quality, as raw hemp fiber typically contains only around 57-77% cellulosic compounds.

Microwave energy (MWE) heating as a promising pretreatment technology for lignocellulosic materials

Conventional heating methods including steam, gas, and electric systems, used for the degumming process have various drawbacks such as lengthy treatment time, inefficiency, and high costs. Microwave energy (MWE) heating has emerged as a promising pretreatment technology for lignocellulosic materials.

MWE offers advantages such as enhanced efficiency, reduced hazards, and shorter treatment duration, with the capability to effectively separate fibers from the cell walls of hemp stems. The researchers have combined microwave energy (MWE) and deep eutectic solvent (DES) treatment methods to degum hemp bast fibers, aiming to obtain pure cellulose fibers suitable for textile applications.

Hemp’s deep eutectic solvent treatment

The results demonstrated that the pretreatment caused structural changes on the surface of the hemp fibers by effectively removing the ‘gummy’ compounds like pectin, oil, wax, as well as lignin and amorphous cellulose while improving thermal stability as a result of gum removal.

Finally, deep eutectic solvents (DESs) serve as an alternative to ionic liquids and possess a high degree of biodegradability. These solvents can be synthesized by combining two or three components, where a specific combination of hydrogen bond acceptors (HBAs), such as quaternary ammonium salts, choline derivatives, and organic acids, with hydrogen bond donors (HBDs), including amides, polyols, and carboxylic acids, is used.

Recyclability and reusability of deep eutectic solvent treatment

The resulting eutectic solution consists of nonsymmetric and large ions with low lattice energy, exhibiting a melting point lower than that of the individual components. The formation of hydrogen bonds enables charge delocalization, which effectively lowers the melting points in the eutectic mixture compared to those of the individual components. One of the advantages of DESs is their ability to provide similar physicochemical properties as ionic liquids (ILs) while being more sustainable, cost-effective, and less toxic.

DESs also possess the desirable traits of recyclability and reusability, making them highly attractive for biomass treatment. Hence, the studies have demonstrated that DESs can effectively extract lignin from lignocellulosic materials without causing alterations to the cellulosic structure.

The cottonization of hemp fibers using steam explosion treatment

The stems of plants like hemp and flax are composed of various structures that collectively provide the plant with water and nutrient transportation capabilities, as well as the necessary rigidity to maintain an upright posture.

Of particular interest for textile production is the layer known as sclerenchyma. Extracting bast fibers from this layer requires separating cellulose from other plant components with minimal effort. Traditionally, the process of retting has been employed to separate bast fibers from the rest of the stem. During retting, the harvested stems are exposed to moisture and microorganisms, causing them to swell and degrade the internal structure.

After drying, the now brittle stems are broken, and the woody fragments (shives) are separated from the mostly intact fibers. In a 2017 study titled Toward the cottonization of hemp fibers by steam explosion: Defibration and morphological characterization by Thibaud Sauvageon and a 2020 study titled Toward the cottonization of hemp fibers by steam explosion.

Flame-retardant fibers by Maria Moussa, steam explosion is presented as a viable method for large-scale commercialization. Steam explosion not only facilitates the extraction of hemp fibers but also enhances their thermal stability.

The steam explosion treatment of bast fibers

Retting and mechanical separation methods are imprecise and often result in defects in the fibers. Chemical treatments, while effective in removing non-cellulosic components, involve the use of strong chemicals such as alkali or sodium sulfate, leading to undesirable waste products that require additional processing for disposal.

The steam explosion treatment of bast fibers requires a power source and high-pressure equipment. The material is first saturated with water and then placed in a steam explosion vessel, where it is heated to approximately 200 °C for a short period. The sudden reduction in pressure within the vessel triggers a steam explosion within the saturated fibers.

The resulting fibers can then be separated and dried before undergoing further processing. This approach offers different advantages: it requires relatively little water, eliminates the need for harsh chemicals or expensive enzymes, yields high-quality fibers comparable in length to cotton fibers, and can be easily scaled up to industrial levels with modest equipment and consumable requirements.

The current industry trend suggests that this approach is likely to be pursued in the future, potentially positioning cottonized hemp and flax fibers as competitors to the cotton industry for the first time since the 19th century.

The Chinese government envisions long term plan for hemp cultivation

Presently, China dominates global hemp production, while France holds the largest producer position in Europe.

Zhang Jianchun, the Director General of China’s Hemp Research Centre in Beijing, envisions a future where expansive Sativa plantations cover 1.3 million hectares of the country’s farmland. Zhang estimates that this scale of production could yield up to 10 million tonnes of hemp plants annually, resulting in approximately two million tonnes of hemp fiber.

The increased cultivation of hemp would bring benefits to China. Firstly, it would offer a substantial new source of fiber for the textile industry, reducing reliance on cotton and freeing up vast areas of cotton-growing land for food production.

Additionally, hemp cultivation would generate additional income for millions of small-scale farmers in economically disadvantaged rural regions. Currently, China produces less than 5 000 tonnes of hemp fiber each year from a cultivated area of approximately 20 000 hectares.

China is the birthplace of industrial hemp

This is only a fraction of the 5.6 million hectares dedicated to cotton cultivation, making China the world’s largest cotton producer with a harvest of around 6.6 million tonnes in 2006. The Hemp Research Centre is working to change this situation and revive hemp’s historical value in Chinese agriculture and textiles.

Zhang emphasizes that China is the birthplace of industrial hemp, with archaeological evidence dating back 4 000 years showing its use for fiber production. Currently, a small quantity of pure hemp fashion fabric caters to high-value niche markets in China. The key to incorporating hemp into fabrics is the process of cottonization.

If 1.3 million hectares were dedicated to hemp cultivation, China could reduce its cotton cultivation by the same amount and repurpose the land for growing food crops.

The Hemp Research Centre has identified suitable areas for hemp cultivation in northern and northwest China, as well as Yunnan Province. These regions are either not major food-growing areas or can incorporate hemp as a rotational crop with soybeans and wheat, allowing farmers to optimize land use and generate additional income.

Cottonized hemp

Cottonized hemp is the result of a process that softens hemp fibers to create a soft, cotton-like material. Fiber technology allows the structure of the hemp to be broken down and woven into a material indistinguishable from traditional cotton.