Alice Harrison

If not viscose for a sustainable fabric, then what? Peter Bartsch, at Lenzing

Lenzing has developed its viscose products, keeping environmental sustainability at the forefront of their innovations, and transparently closing the fiber production loop

Södra. Climate-smart products based on renewable raw materials from the forest

Taking advantage of raw materials from the forest to produce dissolving pulp will later close the textile industry loop. The story of Södra and the OnceMore initiative

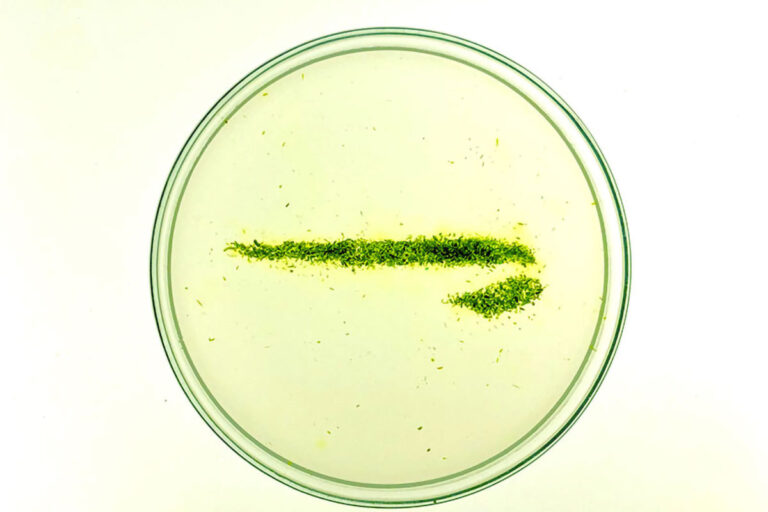

Mantero Seta Re-silk: producing a regenerated material with 100 percent silk by-products

Mantero Seta: tracing the environmental footprint on virgin silk production to ensure that the environmentally harmful steps of virgin silk production are avoided

From Field to Fashion – The Savory Institute puts farmers at the forefront

Through their work they have built 47 global hubs, have signed up more than 100 accredited professionals, trained nearly 15,000 land managers and sustainably developed nearly 15,000 hectares of land