Hemp activewear and denim: higher yield and less water consumption

Robert Jungmann shares insights gained over 30 years, noting advancements that allow for innovative blends of hemp in textiles. Improvements that paved the way for hemp activewear options

Hemp’s market potential: environmental benefits: higher yield and less water consumption compared to cotton, for a sustainable future

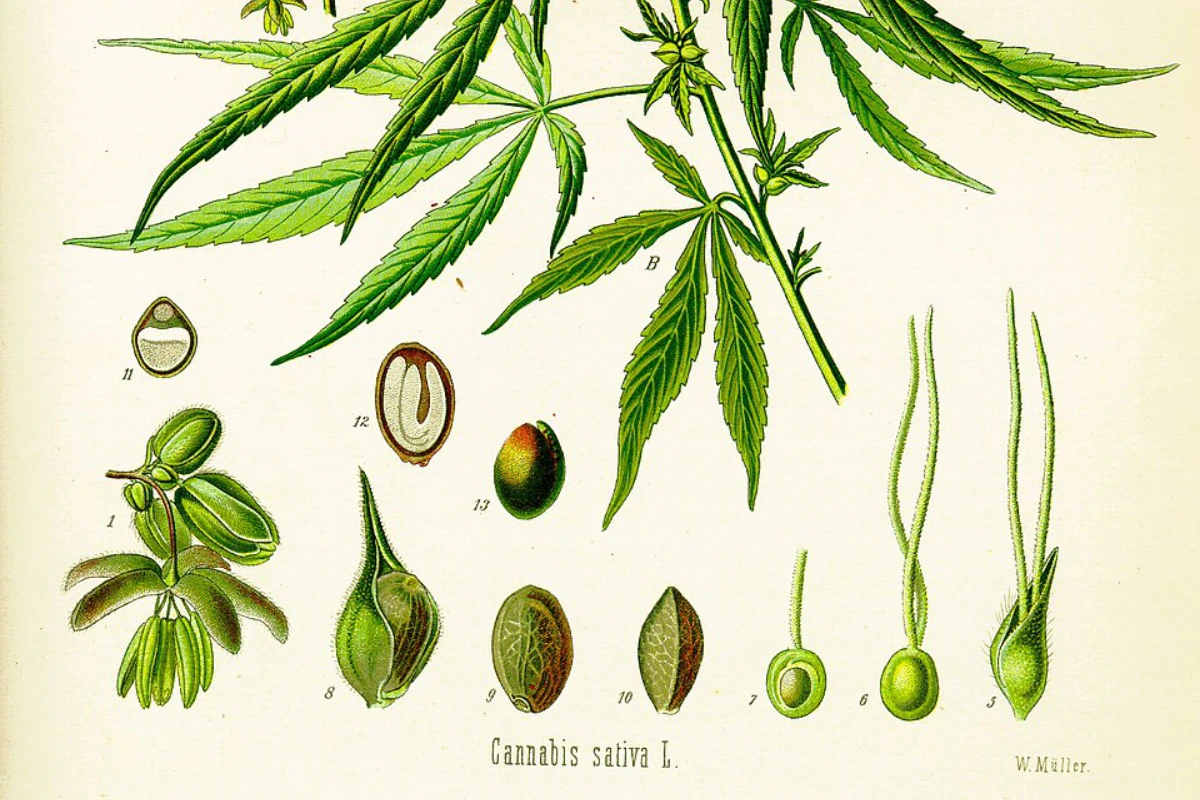

As a plant, hemp offers a series of advantages. Manufacturers can employ it as an alternative to cotton, and it can remediate contaminated soils. Yet, hemp’s politicization has hindered its use, and for Lampoon Magazine, Majdouline m’Saad, the Senior Product Specialist at New Guards Group (NGG), discussed the positive and negative aspects of industrial hemp, the present and future of this plant within the textile industry, and the way forward during a conversation with Robert Jungmann. She leads the strategy and execution of sustainability actions across NGG brands’ supply chain and production, which currently has a portfolio of 9 brands. Jungmann, who started a company called Jungmaven in the 1990s, has always focused on industrial hemp and has been directly involved in policy changes surrounding hemp within the United States.

The surge of new textiles – what’s the role of hemp in this scenario?

Majdouline m’Saad expressed her fascination with the current surge in the industry regarding the creation of new materials. She noted that while there is much to discover, this interest also brings a heightened responsibility for brands. “In the last five to ten years, sitting down with scientists, material engineers, material designers, merchandisers, and buyers, influencing what materials can be and also ultimately the consumption of these materials. We have the power to influence consumer behavior, which for me is the most important thing to do at the moment, in order to achieve a more sustainable way of living.” M’Saad points out that hemp has considerable market value and can be grown without pesticides or fertilizers. In addition, compared to cotton, hemp has a higher yield and consumes less water.

Innovating activewear – how the fashion industry has changed since the 1990s

Robert Jungmann reflects on his decades-long experience in fashion, elaborating on the evolution of the textile industry and the role of hemp. Since founding Jungmaven more than 30 years ago, he has witnessed significant advancements in the sector. “Today we have knit fabric we didn’t have in 1993,” he shares. “I think it was in 1996 when I first saw the first knit fabric, and it was a t-shirt that you could see through; it was not well-knit. It has come a long way, now we’re beginning to blend hemp with some merino wool, some organic cotton and even lycra. We’re giving activewear a chance, and even though it is 30% hemp, at least there is some hemp in there.”

Activewear, also referred to as sportswear, is clothing created for sporting activities. It includes categories such as performance apparel, outdoor gear, and sports-themed clothing. These garments are crafted prioritizing prioritize factors such as protection and practicality in relation to the specific sport and environmental conditions. Manufacturers make activewear with a variety of fabrics and blends, with polyester, nylon, and spandex being the most common. “We always said we have hemp t-shirts, but the fact is that most of it is blended with organic cotton and we often get asked why we have cotton there. It brings a lot of body to the shirts, but the new 100% hemp shirts are innovative. We are also beginning to knit more in the United States and that is helping us to try different combinations and weights of fabric. We were limited to what was available out there, but now we are importing the yarn. We are trying to enter the activewear market and during the first round the biker shorts were basically see through. We knew we had to step it up and make it a little bit thicker. These are the things that the innovative fabrics are helping to deliver; the product that works and what people gravitate towards and what people want more of.”

The issue of supply chain fragmentation: Transparency in the supply chain

Majdouline m’Saad believes that the most significant issue actors in the fashion industry are facing at the moment is handling a large volume of data from a fragmented supply chain. “If our brands were to operate by themselves, if they were a fragmented structure, we wouldn’t be able to align them and gather them under one umbrella and really implement our policies. Most of all, not only the policies or the things we ask our suppliers and vendors to do for us, but also what we do as a group. We have a consolidated vision with FarFetch and what our code of ethics is, what we look for in a vendor, and how we vet them before implementing them within our supply chains.” M’Saad highlights the necessity for brands to centralize their supply chains through stronger, longer partnerships with suppliers and align policies to drive change and meet their sustainability goals.

NNG – Improving denim using hemp

m’Saad disclosed that NNG began its sustainability reshaping about 3 to 4 years ago. “We are not really about disclosing what we do, we have been working internally on so many exciting projects. One of them is a project on denim, and as Robert said, pants are quite a difficult category. We have worked with hemp here and there on some bags or accessories, but it was always a limited-edition drop. The material itself, I believe, has had bad PR and misrepresentation throughout the years; it can work for certain collections, but not for everything.”

The Senior Product Specialist at New Guards Group (NGG) said they spoke with their teams and decided to focus on denim, as it’s the most problematic clothing category they manufacture from an environmental perspective. “We sell high percentages of denim, and we have some stable partners like Candiani Mill. What we did with them for the last six to eight months was developing a new quality of textile”. This textile is a mix of organic fabrics, hemp, and a new biodegradable organic rubber, an alternative to fossil-fuel-based elastane. The result of this blend is a stretchy fabric they intend to use in their menswear and workwear collection, in particular. Their desire to avoid fossil fuel-based textiles is what has drawn them to hemp. “We worked with organic rubber and organic cotton in minor percentages; the hemp fiber is the majority in this fabric. The collaboration with SE Candiani, which is already one of the world’s greenest mills, speaks for itself. We looked at this on every level; how the denim was washed, the fiber, and even the end-of-life cycle.”

Robert Jungmann believes it is positive to see improvements in denim emerging from the market.

“One of our goals at Jungmaven is to be as transparent as possible. We’re always educating. Hemp was illegal in the US until 2018, and our main goal was to get this resource back into use. We educate and display the benefits of hemp. We are attempting to raise the bar for the industry, to create a product that people crave so much that they disregard the idea of having synthetics and don’t want to put it on their skin anymore.” On their website and in their marketing campaign, they share the benefits of this textile, educating their customers. “What is happening right now in China in the Xinjiang region has resulted in a standardization process being brought into the US. It sustains a sense of transparency so that it is clear where the hemp or cotton is originated from. This could be the future of where this industry might be going; from farm to on your back.”

Understanding the textile industry – The pros and cons of using hemp

“I have been in this industry almost 30 years, but I had never been to a hemp farm until the summer of 2022; I went to a farm in San Joaquin Valley in California. There were 20-foot-tall hemp plants that emulated a bamboo jungle, growing that tall in four months. It was the only green area for miles. Hemp uses minimal water while converting C02 into oxygen. It is a plant that can help us find balance on this planet, as there is so much C02 in the atmosphere and we need to be converting that into oxygen.” Said Robert Jungmann to Lampoon Magazine.

According to a 2024 study by researchers from the University of Siena, hemp’s ability to sequester carbon in the soil amounts to 2.7 kg CO2 (ha year). A measure that offsets the Carbon Footprint from the agricultural stage for both traditional and organic outdoor methods in the initial year (Kemda, Marchi et al., 2024). The use of hemp (Cannabis sativa L.) in fashion has a series of downsides as well. The processes of chemical retting, bleaching, and dyeing have a significant environmental impact.

“Unfortunately, designers still need to do a lot of work in this sense, it is not only about consumers and how they choose their clothes. Creators and people with creativity can influence a sense of taste, sometimes due to ignorance and not because they don’t want to do something, but they might modify hemp fiber by bleaching it or using caustic soda to create a special effect, which in turn ruins the hemp. There is this sense of misalignment, and there needs to be a philosophy that cannot be broken. Certain rules need to be established.”

What’s the future of hemp going to look like?

According to Textile Exchange’s ‘Materials Market Report 2025,’ at a global level, the output of virgin cotton fiber dropped from 24.5 million tonnes to 24.1 million tonnes between the 2022/23 and 2023/24 seasons. Of this total, organic cotton takes up 2.9%. On the other hand, in the same season, 0.3 million tons of hemp were grown globally. “The estimated land worldwide available for organic cotton is between 2-6%, yet everybody wants it. The math is clear, and we cannot have organic cotton replace all the cotton that is being used. Recycled cotton has its own issues; even though it is beneficial sustainability-wise, the fibers are shorter, smaller, and break down easily. If we were very good at shifting consumer behavior and breaking apart the bad PR that hemp has had, as well as the aesthetic that it comes with, it could be possible. From an aesthetic point of view, hemp products always have a distinctive look. Certain archetypes are behind certain textiles, and the stigma around hemp should be broken.” Says the Founder and CEO of Jungmaven Ltd.

One of the certifying bodies working with hemp is the Organic Content Standard (OCS). The OCS is a voluntary global standard that outlines the criteria for third-party certification of organic inputs and their supply chains, intended to promote the growth of organic agricultural production. Another one is the US-based, international certification OneCert, founded in 2003 by Sam Welsch.

“There is so much fragmentation within the industry and different schemes of certifications that you can follow. It ultimately depends on your consumer as well; some are more concerned about less harmful chemicals, others about the environment, and, as a result, brands can pick and choose what to focus on. The best approach are the certifications that cover both; less harmful for your health and the planet. As much as I don’t rely on or relish certification, it is the only way to substantiate future claims so that no brand can make false claims without going through a third party.” Stated Majdouline m’Saad.

At Jungmann, they enjoy working with European hemp, due to its properties, and hope to see it grown in Europe, Asia, and North America.“I see it happening in the Carolinas and LA in the US. It would make the most sense and it is where the textile industry is located. I am not sure whether the US would lead the way in terms of textiles, but there is movement towards the CBD and using hemp for building supplies. The more hemp in the ground, the better. I hope to see the textile and fashion industry help create awareness and teach about what can be done with it.”

Majdouline M’saad Karfani

Majdouline M’saad Karfani is the Senior product sustainability specialist at the New Guards Group. She studied Fashion product management at Polimoda.