LOVR™, hemp-based leather: Revoltech’s commitment to upcycling hemp residues

Founded by three friends, the German company Revoltech offers sustainable leather alternatives using hemp residues, contributing to a circular economy and winning multiple eco-awards

Revoltech – Vegan, bio-based leather alternatives for a circular European economy

Revoltech is a German textile manufacturing company based in Darmstadt, Hesse. Founded by three friends, Lucas Fuhrmann, Montgomery Wagner, and Julian Mushövel, the company manufactures leather alternatives that do not utilize crude oil-derived materials, with the aim of contributing to a regenerative and circular future.

Revoltech specializes in two materials, LOVR™ and MATTR™. Both of these materials are bio-based and plastic-free, designed with circularity in mind, meaning they can be recycled or returned to the natural world in a safe manner. For their work, Revoltech won the ‘Green Product Award’ for new materials in 2024, was awarded the ‘German Designer Award’ in 2025, and in the same year, it was the winner of the PETA’ Vegan Homewear Award’.

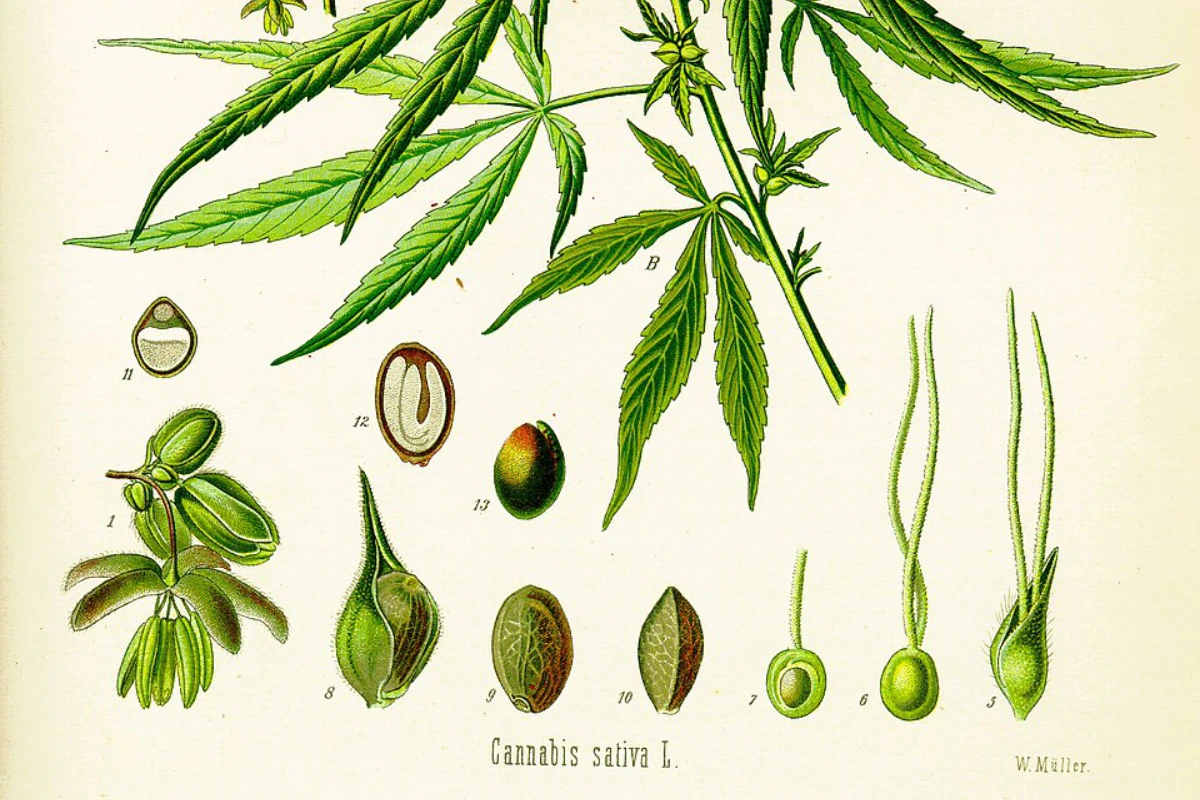

Their LOVR™ is a leather alternative derived from industrial hemp (Cannabis sativa L.) residues. To understand the technology and journey behind this next-gen material that harnesses the technical characteristics of hemp, at Lampoon, we spoke with the company’s CEO, Lucas Fuhrmann.

Understanding textile innovation – The science behind LOVR™ technology

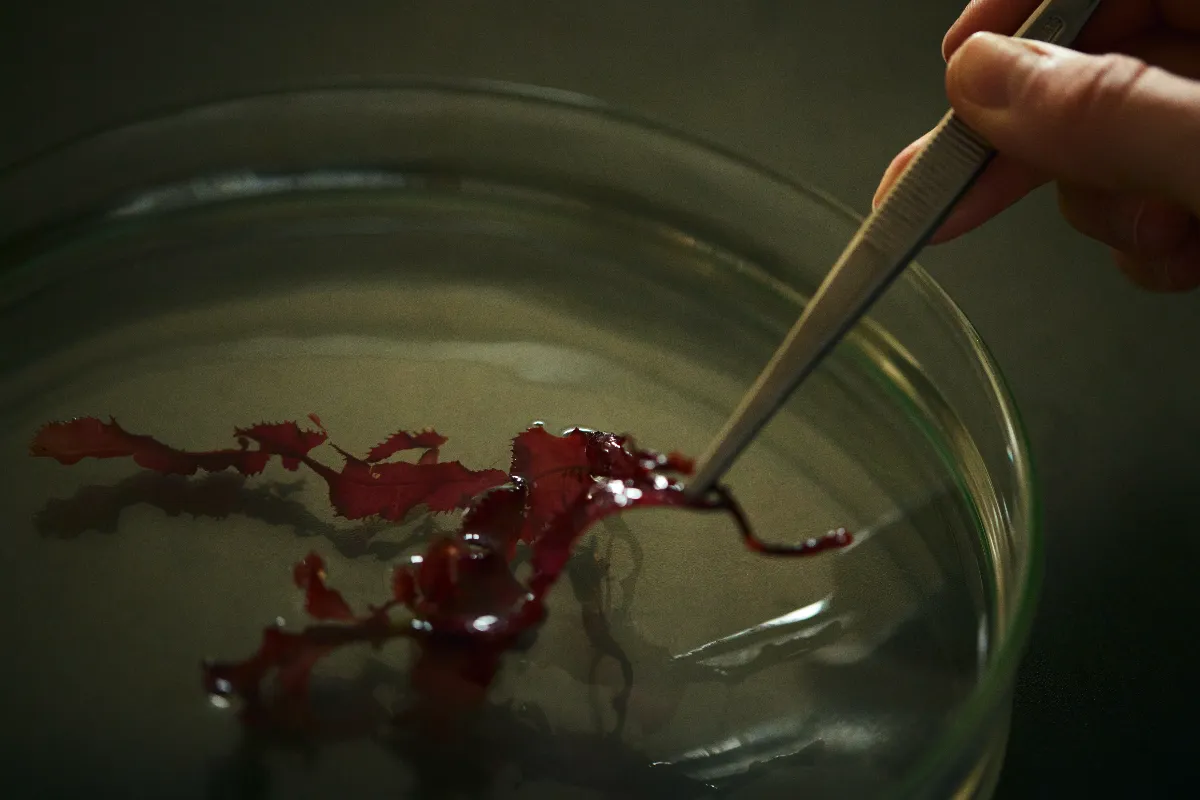

LOVR™ is crafted from hemp residues, which are the by-products of the hemp seed and CBD oil production. This production process involves combining hemp fibers with additives such as waxes and plant-based binders, resulting in a durable, recyclable, and biodegradable alternative to other kinds of leather found on the market.

To achieve this, Revoltech utilizes a process that converts agricultural by-products into a high-performance material using a unique single-layer technology. “This structure gives LOVR™ durability while keeping it recyclable” said Fuhrmann. Created with circularity in mind, the production method developed at Revoltech ensures logevility while remaining plastic-free, water-efficient, and utilizing minimal energy, allowing for a circular approach to water use.

According to the report ‘Scaling Next-Gen Materials In Fashion: An Executive Guide’ elaborated by the Dutch platform for sustainable fashion innovation Fashion for Good with Boston Consulting Group, the scaling up of next-generation materials, textiles presenting characteristics favorable from an environmental and social standpoint, is hampered by a mix of financial, technical, and operational hurdles. To avoid these issues, the production of LOVR™ follows a continuous process using existing machinery, which enables the maximization of this material’s scalability.

How Revoltech is employing the sustainability of hemp residues in textile production

The hemp from which Revoltech manufactures its LOVR™ is sourced locally within the European Union. It is first processed into fibers, then combined with natural formulations, and at the end finished through heat and pressure without the use of synthetic binders or toxic chemicals.

At Revoltech, the idea of choosing hemp residues for LOVR™’s production stemmed from the crop’s environmental benefits. “Hemp is incredible”. This perennial plant absorbs twice as much carbon dioxide (CO₂) as forests, requires no pesticides, and improves soil quality. In addition, their approach upcycles residual materials from farming and agricultural processes. “Using residues from hemp agriculture means we’re not competing for land or food crops, we’re upcycling what would otherwise be agricultural waste”.

The company’s approach to materials sourcing and partnerships prioritized sustainability. The team at Revoltech chose to collaborate with farmers from Germany and neighboring European countries who cultivate hemp for seeds and oil. This regional sourcing strategy reduces greenhouse gas emissions generated from transportation and promotes traceability. “It’s part of our vision to create circular material ecosystems within Europe”. The textile company’s chief executive officer remarked to Lampoon.

Revoltech’s academic collaboration – a development journey of cooperation and science

Fuhrmann’s own experience in the fashion industry sparked a desire to create sustainable materials that align with the goal of protecting the natural world. “I started in the fashion industry, actually during an internship, and saw firsthand how resource-intensive and polluting it was. That was the moment I realized we needed to completely rethink materials, not just tweak them. I wanted to create something that performs like the materials people love, but works in harmony with nature” explained Revoltech’s .

The development journey of Revoltech and LOVR™ was characterized from the get-go by its collaboration with the academic world. The story of this innovative technology involved extensive experimentation and collaboration. Revoltech, in fact, maintains a close relationship with the Technical University of Darmstadt (TUD), where it originated as a spin-off. This connection fosters continuous exchange, keeping the company aligned with the latest technological advancements. “We’re still based on campus. We keep a close connection through shared lab space and smaller research projects. It’s a continuous exchange that keeps us connected to academic research and new ideas”. Clarified Lucas Fuhrmann.

This partnership with the Technical University of Darmstadt, one of Germany’s leading technical universities, provided critical research support and refined the production process, corroborating a variety of aspects of the materials’ technology. “It started with small experiments and a lot of trial and error. I was fascinated by how agricultural residues could be transformed into something entirely new. Over time, that curiosity turned into a working process. Later on, we began collaborating with the Technical University of Darmstadt to deepen the research and validate parts of the technology. That partnership helped us refine and scale what we had already developed”.

The daily operations at Revoltech reflect their focus on science-based innovation. “It’s a mix of lab work, prototyping, and collaboration. Our team of 15 brings together material scientists, engineers, designers, and business minds, all working toward the same goal of advancing bio-based materials. Some are deep in R&D, refining our next-generation formulas. Others are in close exchange with partners from the automotive, fashion, or interior sectors to bring our materials into real-world applications. And of course, some make sure our operations and finances stay as solid as our materials. Every day looks a little different, but it always revolves around pushing circular innovation forward”.

Revoltech’s environmental performance assessment

As a plastic-free leather alternative, LOVR™ avoids the ethical and environmental downsides associated with both animal leather and its artificial equivalents, which are commonly used in fashion, furniture upholstery, automotive accessories, and other applications. These alternatives are manufactured from non-woven fibers, such as polyamide, combined with a resin like polyurethane.

Revoltech assessed the environmental impact of LOVR™ through a Life Cycle Assessment (LCA) based on the GHG Protocol. “The result showed LOVR™ emits only 0.51 kg CO₂ per square meter, 99% lower than leather. Hemp’s carbon absorption even gives it a nearly neutral footprint. We’re constantly refining the process to reach full carbon neutrality”.

Revoltch impact on fashion’s supply chain

Next-generation materials, such as those developed by Revoltech, can offer a transformative opportunity for the fashion and automotive supply chains. By choosing circular alternatives to genuine and synthetic leather, brands can reduce greenhouse gas emissions and pollution while integrating better materials into existing production processes.

Their plans involve scaling up their operations. “We’re building partnerships with existing manufacturers to scale production using their infrastructure. This minimizes investment and accelerates adoption. In 2026, we’re focusing on expanding material sales of LOVR™ and preparing large-scale production for MATTR™. By 2030, our goal is to become the leading supplier of leather alternatives globally”.

Lucas Fuhrmann

Lucas Fuhrmann is the Co-Founder & CEO at Revoltech. He earned his Bachelor’s degree in Philosophy and Economics at the Universität Bayreuth, and his MS at the London School of Economics and Political Science (LSE).

Roberta Fabbrocino