Hemp biocomposites: food packaging solutions using hemp biomass

An international team of scientists studies the valorization of hemp biocomposites, revealing its potential in developing sustainable food packaging solutions

Hemp biocomposites for packaging: the research at Western University (WU), London, Ontario

A recent study conducted by Canadian researchers at Western University (WU) in London, Ontario, suggests that hemp bioplastics could find their first major application in the packaging industry.

The researchers grounded up hemp stems to create a powder, which was then used to replace high-density polyethylene pellets typically found in conventional plastic. The hemp powder was incorporated into the existing packaging manufacturing process without the need for specialized technology or additional procedures.

Hemp offers advantages over heavier and costlier alternatives such as metal and glass

According to the tests conducted, the hemp-based material falls short of meeting the strength and malleability standards set by conventional plastics. It surpasses other plant-based materials in terms of strength and malleability, making it suitable for various applications. Elizabeth Gillies, a chemistry professor at Western University and co-author of the research, explained to Canada’s CBC broadcaster that when it comes to packaging, hemp offers advantages over heavier and costlier alternatives such as metal and glass.

The manufacturing process of Hemp biocomposites

A hemp biocomposite refers to a composite material made by combining hemp fibers with a matrix material, typically a polymer or resin. To create a biocomposite, hemp fibers are separated from the stalks of the plant and the hurd – the inner part of the stalk – gets micronized.

These two elements are incorporated with the matrix material often derived from renewable resources such as plant starches, vegetable oils, or other natural polymers. The commercially available hemp materials in the market are predominantly fiber-reinforced biocomposites, with the hemp fibers specifically utilized to reinforce an existing polymer, improving its strength, stiffness, and resistance.

Greenwashing alert: not all of the polymers used in hemp biocomposites derive from plants

It is to note that not all of the polymers used in hemp biocomposites are plant-based. Petroleum still makes up for the majority of polymers used in hemp biocomposites today. This leads to a situation where numerous hemp plastic products marketed as sustainable are essentially a blend of petroleum-based plastics mixed with hemp fiber.

Alternatively, some hemp biocomposites utilize plant-based polymers like PLA, commonly derived from corn or kenaf. In the United States, sourcing PLA that is not derived from corn is highly challenging. The chance for a bioplastic made entirely from hemp requires breaking down and chemically reconstructing the cellulose found in the hemp plant into a composite bioplastic. Only in that case, the material is 100% biodegradable, featuring a tensile strength that is much higher than that found in the plastics derived from fossil fuels.

Hemp biocomposites performs better than plastic, study at Western University shows: the advantages

Several are the advantages to using hemp biocomposites. It Improves the quality of the soil and carbon neutrality: Employing hemp to the manufacturing of biocomposites is proven to increase soil quality. Hemp stalks have a shorter growth period of approximately 4 months against 20 to 80 years for the trees to reach maturity. The overall process is much quicker and requires fewer pesticides or herbicides.

Hemp plays a vital role in soil enrichment as it replenishes essential nutrients. In certain regions, it is cultivated specifically to extract pollutants like zinc and mercury from the soil, as well as a rotation crop, promoting soil recovery between the cultivation of other crops. Moreover, hemp plants absorb great amounts of carbon dioxide during their growth, making them a carbon-neutral material.

The biodegradability of hemp biocomposites

Many hemp biocomposites are biodegradable, meaning they can naturally break down over time without causing harm to the environment.

Hemp biocomposites can be molded into various shapes, allowing for versatility in design and application. Hemp biocomposites are lightweight and can be used in various applications, including automotive parts, construction materials, packaging, and consumer goods. They combine the strength and sustainability of hemp fibers with the versatility and potential biodegradability of bio-based polymers or resins.

Henry Ford and the first hemp car body prototype: the Hemp Car or Soybean Car

Henry Ford was the first to understand and experiment with the potentialities of hemp-based materials. In 1937, Ford created a car body prototype using a hemp-based plastic material, known as Fordite or Hempcrete, that was believed by Ford to be the one to revolutionize the automobile industry.

Combined with a resin binder, the material was used for the car’s exterior panels, including the fenders and body panels. Ford also implemented various components of the car made with soybean plastic. The car body could be fueled with either vegetable oil, hemp-derived oils, or biofuel.

To demonstrate the elasticity and the strength of the new type of bodywork to the journalists and the public, Ford had himself filmed while forcefully hitting the back of the car with a mallet, and no, the car didn’t bend or break.

Unfortunately, due to various factors, including the introduction of synthetic materials like nylon and the restrictions imposed on hemp production in the United States, the widespread adoption of hemp-based materials in car manufacturing did not occur. The project was eventually discontinued, and the hemp car never entered full-scale production.

The future of hemp based material does not rely on hemp biocomposites but in the development of hemp-based polymers

Biocomposites, despite their existence for many years, have limited applications in packaging due to their inherent rigidity. Therefore, it can be concluded that hemp-derived materials lie in the development of hemp-based polymers, which, like other plant-based polymers, are obtained directly from the cellulose of the hemp plant.Although hemp-based polymers have been successfully developed at the laboratory level, they have yet to become commercially viable. The main obstacle to the commercialization of hemp-based polymers is the nascent infrastructure of the industrial hemp industry which, like any robust infrastructure, takes time, funding, and support from the public and private sectors.Additionally, hemp-based polymers will face challenges related to their end-of-life cycle and compatibility with waste management infrastructure.

The research paper provided by the Western University, London, Ontario contributes to the growing body of work and excitement surrounding the use of hemp fiber in bioplastics. It provides a realistic assessment of the business potential, acknowledging that biomaterials are currently more expensive to produce than traditional plastics.

Using the whole thing – Can we employ hemp biomass to make food packaging?

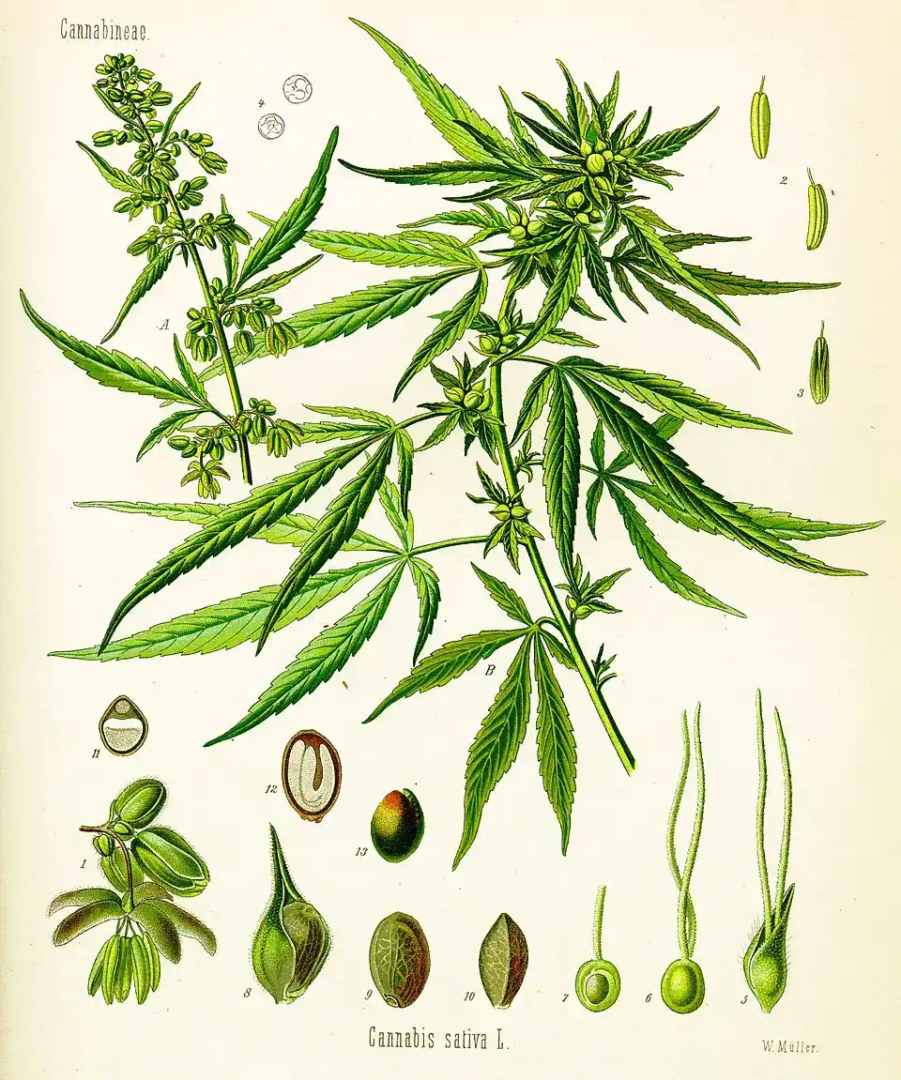

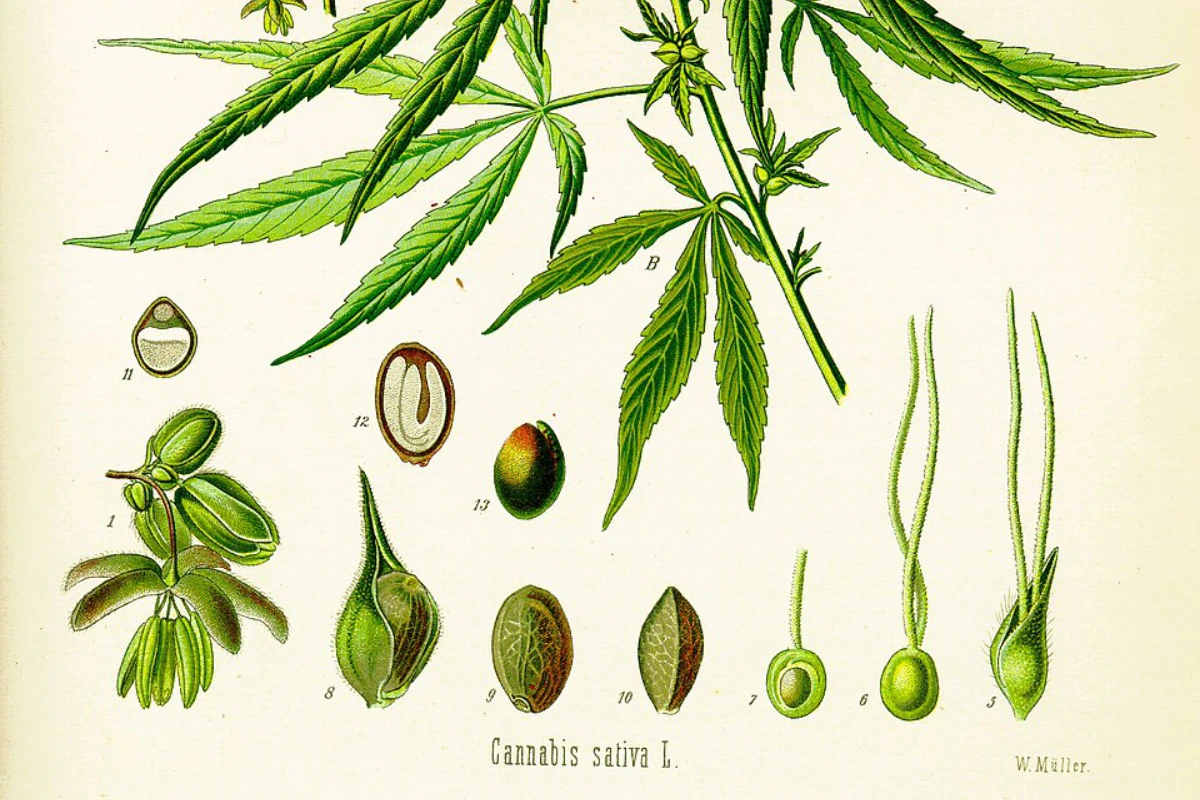

Hemp biomass is the plant material left over after the cultivation and harvesting of the industrial hemp flowers (Cannabis sativa. L). An international team of scientists investigating the valorization of hemp biomass through sustainable methods has shed further light on the potential of hemp in next-generation food packaging. For their research, the scientists from the Lithuanian Research Centre for Agriculture and Forestry, the International Centre of Excellence in Seafood Science and Innovation, and the Integrative Science Center of Germplasm Creation in Western China focused on green extraction and processing methodologies.

These methods, such as deep eutectic solvents (DES), microwave–assisted, supercritical CO2, ultrasound–assisted, enzymatic hydrolysis, and subcritical water treatments, enable the maximization of hemp fiber’s bioactive properties and potential for use in packaging manufacturing.

What they wished to uncover was whether the integration of a multitude of these methodologies could improve the barrier properties, biodegradability, pigment utilization, and mechanical and biodegradability performance of hemp-based food packaging. Their analysis, published this Autumn in the scientific journal ‘Trends in Food Science & Technology ’, shows that the properties of hemp, combined with green processing technologies, can help scale up the conversion of hemp biomass into functional food packaging materials.

From hemp biomass to sustainable food packaging, thanks to science

Environmental concerns associated with the production and use of fossil-fuel-based consumer goods abound. Their use and production are a source of profit for the fossil fuel industry, with microplastics contributing to land and marine pollution, and infiltrating human organs and tissues, including the brain, heart, and stomach.

Thanks to its bioactive functionality, biodegradability, and mechanical strength, hemp-based biopackaging can become an alternative to conventional plastics, helping mitigate the issues associated with the conventional ones. Hemp biomass is composed of 40–77% cellulose, a material that can be utilized in the production of bioplastics with mechanical and barrier properties, such as UV-resistant films.

Hemp biomass shows promise for environmentally friendly food packaging, but industrial and technological barriers, such as issues with the scalability of sustainable valorization, prevent its widespread use. The primary problem is the inhomogeneity of hemp feedstock, which affects packaging performance, processing outcomes, and the uniformity of fiber quality.

Methods such as DES-based delignification and supercritical CO2 extraction can enhance the functionality of hemp biomass-based bioplastics and reduce their environmental impact. According to the study’s authors, though, the resolution of the criticalities associated with hemp biomass variability and the high enzymatic costs would make the use of Artificial Intelligence-driven optimization and a homogenization of regulatory standards a necessity.

Lithuanian Research Centre for Agriculture and Forestry

The Lithuanian Research Centre for Agriculture and Forestry is a state research institute. It conducts research and developments in agronomy, forestry, ecology and environmental sciences. It was established in 2010 from the merger of three related research institutions, and it operates out of the city of Kaunas.

Martina Tondo, Roberta Fabbrocino