Carbon-negative innovation: the power of hemp fibers

Hemp and carbon – combining hemp fibers and carbon negative coconut biochar reduces drying shrinkage in recycled aggregate concrete (RAC), enhancing its overall performance

A carbon negative crop – hemp, photosynthesis, and carbon storage capacity

Hemp is considered a hardy species in that it is able to grow under suboptimal conditions in terms of both soil fertility and temperature and water availability. It is a plant that can store carbon dioxide at higher temperatures (up to 30-35 °C) and thus perform photosynthesis and continue the phenological process unhindered even under more extreme conditions.

One hectare of hemp can absorb from 8 to 22 tons of CO2 per year, while a hectare of tree plants averages around 6 tons as reported by Hudson Carbon in New York. Focusing on the carbon storage capacity of hemp is possible when it comes to green building use. This CO2 is sequestered in the stem, which accounts for 80 percent of crop biomass-so using its products to make durable materials (green building, bioplastics, biochar) allows CO2 absorbed from the atmosphere to be sequestered for a period of time. This explanation – with further considerations – allows us to understand the sentence that claims how one hectare of hemp can absorb more CO2 than one hectare of forest.

Understanding environmental action – What is carbon offset?

Carbon offsetting is defined as any activity aimed at offsetting the emission of carbon dioxide. It may represent in the future an opportunity for a reed farmer to increase their income. The introduction of a carbon credits market will make it possible to quantify and reward the contribution. One carbon credit is equivalent to one ton of carbon dioxide stored.

Plants and carbon offsetting – Carbon Farming

Carbon Farming refers to an agro-ecosystem that can harness the natural ability of soil and plants to store carbon by removing it from the atmosphere. Contributing to the European Green Deal to mitigate and innovate against climate change is a concept to be encouraged especially in the agriculture and forestry sector.

From December 2021, the commission through the “Communication on sustainable carbon cycles” has given the green light for European agriculture to enter the carbon credit market through the practice of carbon farming. The goal is to save about 42 million tons of CO2 in the EU by 2030. Carbon farming or agro-ecology has great potential to generate positive ecological, economic and social impacts. As per today, hemp is just a potential asset.

Sustainable construction materials: addressing waste and enhancing concrete performance with carbon-capturing materials

In the construction industry, the carbon-capturing capabilities of hemp as a crop can be maximized and harnessed to their full potential by combining it with other materials that possess similar qualities.

This construction industry is responsible for more than a third of all waste generated in the European Union, according to estimates by the European Commission. At a global level, the construction and demolition industry generates more than 3.0 billion metric tons of waste each year (Akhtar and Sarmah, 2018; Pristerà et al., 2024). Concrete debris accounts for 40-60% of this waste (Zhang et al., 2023).

Incorporating recycled resources, recycled aggregates, into high-performance concrete has been a focus of research in civil engineering. The use of recycled aggregate concrete (RAC) yields economic benefits and reduces the industry’s carbon emissions. Yet, this recycled material has its technical disadvantages. In recycled aggregate concrete, drying shrinkage increases by about 15% to 80% compared to natural aggregate concrete.

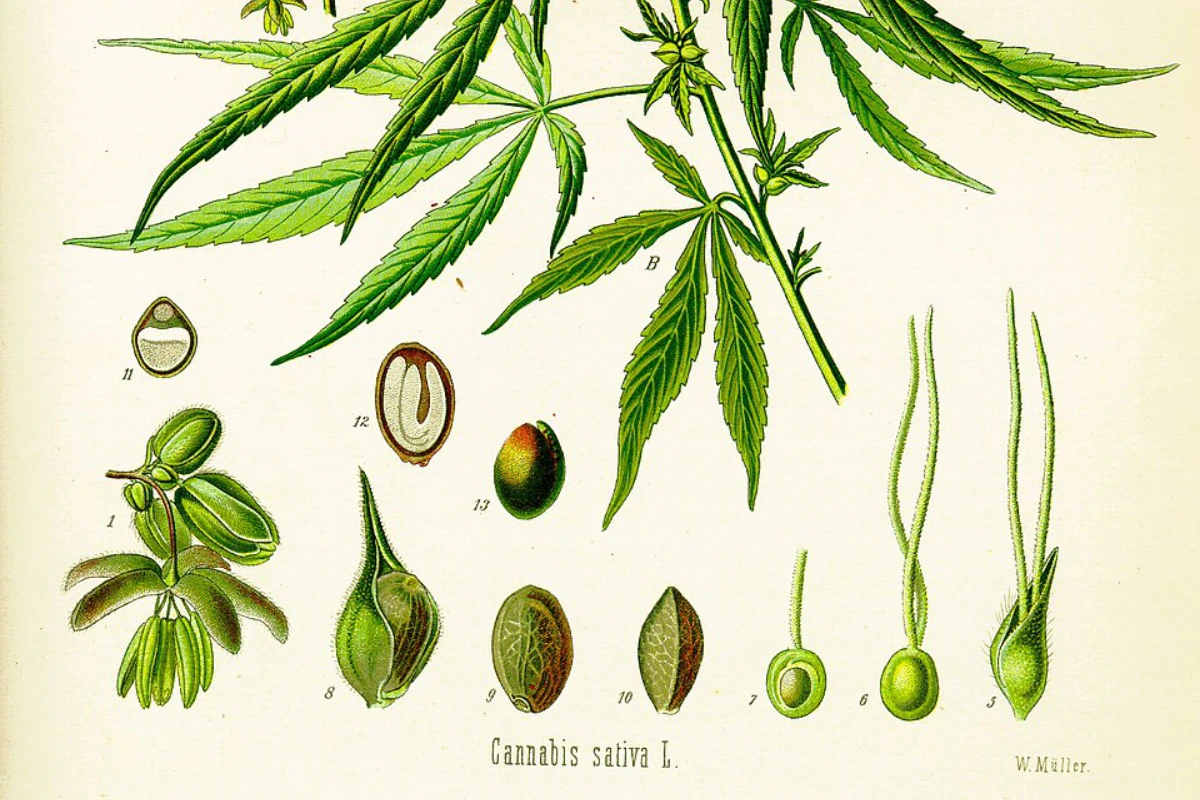

Industrial hemp (Cannabis sativa L.), in the form of hemp fiber, serves as a cost-effective vegetal fiber comprising approximately 60% to 70% cellulose, 15% to 20% hemicellulose, and 10% to 15% lignin. These characteristics suggest that it may contribute to addressing the prevalent issues in this domain.

In a study published this December in the scientific journal ‘Resources, Environment and Sustainability’, a team of researchers from the Technische Universität Dresden, the University of California, Davis, and the Shanghai Jiao Tong University has investigated the results of combining hemp fiber and activated coconut biochar as an internal curing material to lessen the drying shrinkage of recycled aggregate concrete.

Integrating hemp fiber and biochar to mitigate drying shrinkage in recycled aggregate concrete

For the study, the researchers analyzed samples containing varying formulations of concrete modified with hemp fibers and biochar, as well as plain recycled aggregate concrete. Biochar is a carbon-negative material manufactured from biomass through a thermochemical conversion process known as pyrolysis. On these samples, they performed flexural and compressive strength tests, a microstructural analysis, and measurements of drying shrinkage.

In addition to these tests, the scientists tested the samples for chloride ion migration using cylindrical concrete specimens, where they identified the chloride migration depth by observing the formation of AgCl precipitation. The scientists performed water absorption tests in accordance with ASTM C642-13. The specimens were dried in an oven, air-cooled, and then immersed in a water tank for two days. After this period, they recorded the saturated mass and calculated the percentage increase compared to that of the oven-dry specimens.

This study employed a cradle-to-gate scope, focusing on emissions and expenses from the production of concrete through to transportation to the construction site. In addition, the researchers employed life cycle analysis (LCA) and life cycle costing (LCC) assessments to evaluate the environmental and financial impacts of incorporating coconut-based biochar and hemp fiber into recycled aggregate concrete.

The integration of biochar reduced the concrete fluidity caused by particle friction and water absorption. In the mix with 30% biochar and 30 mm fibers, the compressive and flexural strengths increased by 28% and 34%. Thanks to the implementation of coconut-based biochar and hemp fiber, the 28-day drying shrinkage decreased by up to 96%. The increase in biochar content and the rise in fiber length resulted in a decrease in the chloride migration coefficient, enhancing the durability of recycled aggregate concrete. In addition, water absorption decreased by 34% with higher amounts of biochar and longer fiber lengths, which corresponded to an increase in strength.

Shanghai Jiao Tong University

Shanghai Jiao Tong University is a public university founded in Shanghai, China, in 1896.

Roberta Fabbrocino