From cement to hemp: researchers invent bio composite for sustainable building

New York’s Seed To City Hemp Initiative: A project to tackle the supply chains and cut down emissions in the building manufacturing industry using hemp fiber

The building sector in New York City. An opportunity for hemp

The building sector in New York City and in general in the United States is in dire need for materials that reduce their embodied carbon, a factor that refers to the emissions during the construction of a building rather than when it is in use. In the past twenty years a lot of research has been put into reducing energy and making that energy come from renewable sources. According to the United Nations, the trend is to develop a new approach to make buildings not solely as energy users but also energy producers. At the same time, materials that are very high in carbon footprint are still used and hardly replaced. So although the energy reduction is going well, the carbon footprint of the materials is going up. In the future, the carbon footprint of the material will be a more important factor that the carbon footprint of the energy used in buildings.

New York is one of the signatory cities of the Paris Agreement, a legally binding international treaty on climate change whose goal is to primarily limit the rise of global warming. According to the treaty, the City is pursuing legislation to require that all large buildings limit fossil fuel use below intensity targets and reduce at least 40% of the urban carbon footprint by 2030 and 2035. Currently, the system is showing some limits especially in the area of materials.

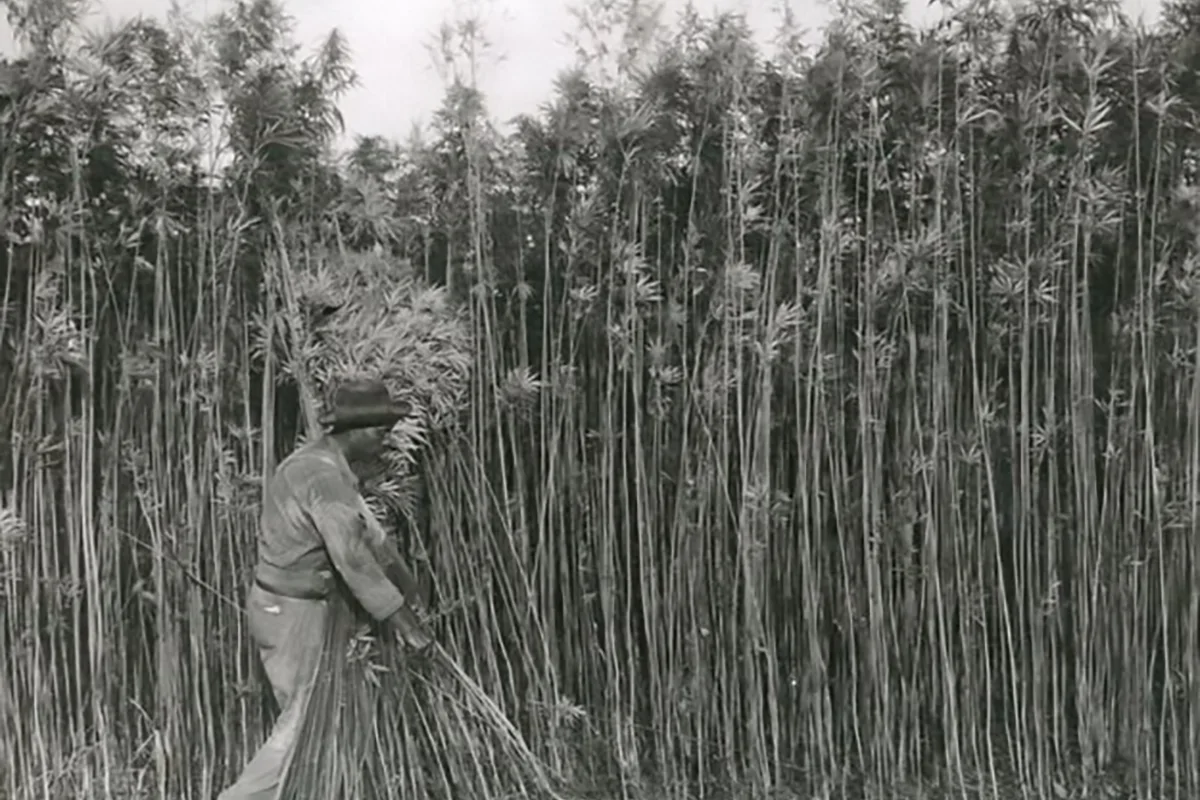

Hemp cultivation for infrastructure is a relatively premature sector in the United States. It’s further ahead in Europe, especially in Germany, England and even France and China as well, in terms of processing technologies. The US has a brute force approach to processing fibers and it’s rarely done by hand; instead it is processed quickly, put through machinery that beats up the fibers to separate them from the hurd, degrading the quality of the raw material. The best quality fiber available is from China, because they are processing hemp by hand, breaking and peeling away the outer bark to get the fiber.

The Seed To City Hemp Initiative

The Seed To City Initiative carried by the Rensselaer Polytechnic Institute targets this issue, combining expertise in design, engineering and business to develop a holistic plan for a sustainable and economically viable hemp industry for New York. Around 1860, Rensselaer Polytechnic Institute innovated in the construction of one of the first steel cable bridges, the Brooklyn Bridge. The innovation back then was the replacement of the Hemp tow ropes used extensively until then, with steel cables that significantly extended the strength and span of bridges. One hundred and sixty years later Rensselaer Polytechnic Institute is changing route this time replacing steel reinforcement in cement based construction, with next generation hemp composite rebar that would significantly extend the service life of concrete structures while crucially also reduce their carbon footprint.

The Seed to City Hemp Initiative puts together two different interests: one is a reason for farmers to cultivate hemp—so that they can have an industrial area they can sell to— and the other for the building industry, which is in need of renewable materials. By coupling the two sectors, this initiative aims to tackle the whole supply chain. Lampoon spoke to the leads on this project.

Switching to processing of natural fiber

Daniel Walczyk, Professor and Director for the Center for Automation Technologies and Systems, focuses on manufacturing processes primarily with composites states. He’s been working with synthetic composites for about twenty years, mostly made with synthetic materials. He has been doing a conscious switch to processing of natural fibers used in composites and also bioplastics. «The harms these materials have been doing to the environment, especially with their processing and end of life, even though they have their benefits on their performance products, such as lightweighting and energy production, are problematic».

Alexandros Tsamis, Associate Director at CASE, Center for Architecture, Science and Ecology at Rensselaer, has a background in architecture and works with composite materials in order to figure out how to reduce the carbon footprint of the building industry. «The building industry is the most carbon intensive activity that humans are involved in and partly it’s because of the way we treat materials: the way we extract them, transport them and install them. The general area of research is figuring out what alternative sources of materials and alternative methods of processing we can have, and how we can use advanced manufacturing in order to produce high performing but low carbon materials for the construction industry».

Other researchers from humanities, system engineering and material science are trying to cover the whole spectrum of activities, from cultivating to processing, until it becomes a renewable material.

Plans to overcome the lack of effective processing methods and equipment

According to the RPI team, the focus of their research is on hemp fibers and secondarily on the hurd, a white wood like material. While the latter is more researched and worked on to generate hempcrete or hemp blocks— a more traditional way to use hemp— the fibers are amazingly strong. «They are one of the strongest fibers that exist in nature. A bio composite with hemp has similar properties to glass epoxy composites which are used in Rebar technology. It has a higher strength per weight than steel that is the primary material for Rebar. Hemp composites consist primarily of hemp fibers, which are all cellulose. The hemp fibers are degummed, meaning that they are soaked in a caustic solution to remove the different gums that hold them together (hemicellulose, lignin and pectin), and then the raw fiber degummed is combined with a thermoplastic matrix to make the bio composite. The plastics we are interested in are either bioplastics like polylactic acids which are made from corn or PHA made from a bacteria consuming biological waste or recycled plastics like PET».

Walczyk explained they have already developed a machine to automate the process of separating the fiber from the hurd, without damaging the fibers, in the same way it is processed by hand. It is called a peeler and decorticator. «Conventional machines damage the fiber in the extraction process. The result that comes out from the peeler and decorticator is very long ribbons, which was so far only obtainable if done by hand. It’s low cost and potentially, with multiple machines, it can be done in high volume».

Another method included in the hemp Rebar manufacturing process is the automated—also called sustainable— degumming, a smarter way to deal with the long fiber strips that simplifies the processes compared to what is done traditionally. Since this process is automated, it uses less of the caustic solution.

The natural fiber based Rebar technology

The hemp fiber is by weight comparable to fiberglass. «The application of a natural fiber based thermoplastic Rebar technology could directly replace the fiberglass river and, in some cases, even the plain steel Rebar».

Tsamis explained that the concrete industry is suffering from one major issue, the corrosion of steel, a phenomenon that generally reduces the lifetime of structures. On top of that, there is also a limited amount of time the material will last. After that time has passed, it has to be replaced or has to be fixed, causing direct and indirect issues. «We decided to do this having in mind that a local production facility would be more sustainable and environmentally more friendly than one Rebar manufacturer that exists somewhere in the world that distributes vary but everywhere. Mainly, there is one place in the United States that makes most of the material and there are vendors all over the world. This is a failure in the system and projects a backwards thinking mentality».

The thermoplastic Rebar gives further advantages, from the user’s machine to the contractors, to the people that are installing it. It is a competitive choice in the market, but it’s not considered attractive as a greener option. It’s not the green aspect of it that attracts people: this manufacturing technology is small scale and it can be taken on the site. Traditionally, Rebar is bought from the factory to the place carried in large quantities. It is taken on the track with the Rebar in the back, unloaded with cans, and then it can be customized by hand bending the Rebar into shape.

Natural and thermoplastic fibers

Differently, the machine developed by Tsamis and Walczyk can be installed directly on the site. It has the size of a small car and it receives a flexible rope as an input, made out of natural and thermoplastic fibers of different mixtures. Coming out from the side are bobbins of rope, not straight bars that are rigid. The machinery receives the rope through a process of preheating with an AREF technology—similar to a rapid heater—, then, when it gets into a heated chamber, it gets melted and solidified. Finally, it gets pulled on the other side, where it can get bent and cut to different shapes and textures.

This way the contractor has the chance to get any desired Rebar and make it on the site, creating logistical and manufacturer advantages. This procedure has its own challenges. They have to produce at least 2m a minute of Rebar to be able to be competitive with other production rates of Rebar. The automated part of manufacturing like cutting and bending the product into shape are doable but still challenging, requiring further work on them.

The social ramifications of hemp cultivation and hemp composite manufacturing

The goal is to develop this type of infrastructure, where farmers would benefit from several different factors. They would have a cash crop that has a higher value, considering agricultural crops that aren’t used for food. For most farmers, especially in New York State, the crops are used to feed dairy cows; if the farmers have the possibility to rotate a high value crop on their farm, it would have a significant positive impact. A renewable material economy is an opportunity to engage in economic activity in a more equitable way than it is happening now with traditional sources of materials. The typical manufacturing models are centralized, bringing all the material to the site to do the processing.

«A distributed model works better for farmers» explained better by both Tsamis and Walczyk. «You have either individual farmers that are large enough to use the raw material processor to be bio composite, or you can have distributed locations around the State where farmers don’t have to travel far, take their hemp stocks and have them processed and then transported with less weight because constituents are separated within the facility where the bio composite materials are made. If smaller production facilities are distributed in the country they are stationed in, it changes the way manufacturing and distribution are organized. Small scale machines can be operated from different sites and production rates, without the need for mega producers. These are the social and ideological point of views behind the research that informs about the scales, the complexity and the accessibility of this technology that we are creating at a different level».

These types of materials, called biogenic, are grown in the field and distributed by nature because they are expensive in the land and not concentrated in a point. This way, farmers of different scales can participate. Tsamis and Walczyk believe that this might be a good indication for the system to work on. It remains an undervalued sector because hemp still doesn’t create an economic incentive for farmers. It is very low value material, and it is more expensive than what it replaces.

Hemp-based material as a replacement for fiberglass and steel

Mostly used in insulation, cladding, surface coating and roofing, fiberglass is one of the first most used materials in built infrastructure. A new generation of material gave life to glass reinforced plastics, a semi-finished structure mechanically and chemically much more durable than the previous type, but has a much less sustainable production system. Industry has already established thermoset and thermoplastic composites, with the latter known to be much less polluting than thermosets.

From the whole lifecycle perspective, it becomes a little bit uncertain to calculate the amount of resources implied when it comes to hemp composites because the supply chains are not there. «You need water to grow the crops but you also need water to extract and wash the metals from the Earth. At the moment we cannot have an exact comparison between the two things because our technology is not established. If we take steel into account, it takes thousands of Celsius degrees to melt and shape it—for a Rebar it’s 200゚C, so there’s a magnitude of difference in the amount of energy you put into the processing of the two things. If you spend a lot of energy to make something that lasts fifty years, and you spend the same amount of energy to build something that lasts twice the time, the embodied carbon per year of the structure is much less. We have done the calculations and it’s approximately half the carbon footprint of the fiberglass; almost the same as recycled steel but with a much bigger lifetime, and it’s about a third of the cost of stainless steel».

In terms of embodied energy, considering the current technology and existing supply chains, the two experts estimate that the hemp fiber and hemp based Rebar will have half the embodied energy compared to glass epoxy Rebar. «Since the materials are not transported for many miles, we get rid of a lot of the material handling of the transportation costs which are significant. Those oftentimes eclipse the actual energy consumption of many records from manufacturing. The same can be said for water usage if you compare analogue manufacturing and distribution models».

The Seed to City Hemp Initiative

A project by Rensselaer Polytechnic Institute combining expertise in industrial design, engineering, and business to develop a holistic plan for a sustainable and economically viable hemp industry for New York.