Hempcrete: the building material that sequesters CO₂

How hemp could become a game changer in the construction industry: a smaller footprint than traditional concrete and the ability to sequester CO₂ for up to one hundred years

What hempcrete is and why it matters in sustainable construction

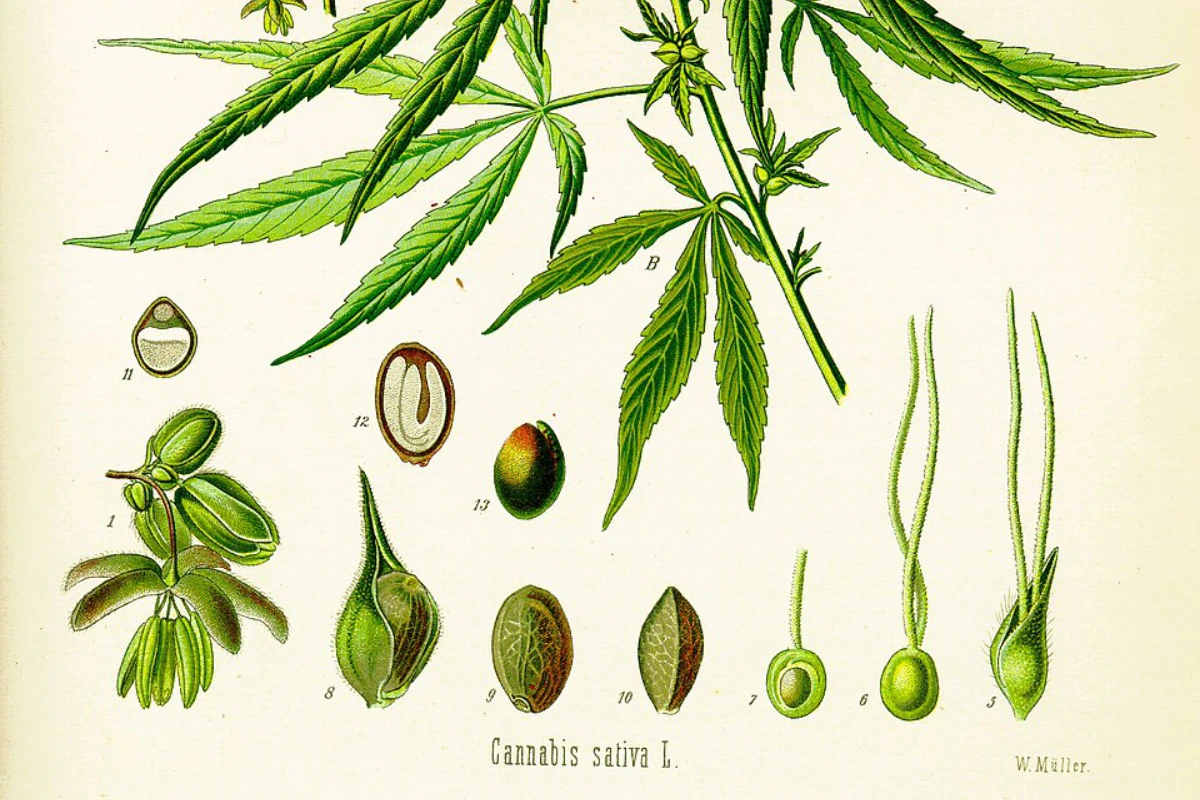

Hempcrete—a portmanteau of hemp and concrete—is a plant-based building material made from hemp hurd, lime, and water. The hemp stalk consists of two primary components: the outer bast fiber, commonly used in textiles, and the inner core, known as the hurd. Traditionally considered agricultural waste, the hurd has a woody texture and serves as the main ingredient in hempcrete. Lime acts as a natural binder, holding the mixture together and creating an effective insulating material. Although hempcrete can be formed into structural building blocks, the term traditionally refers to its insulating properties rather than to a load-bearing function.

How hempcrete is used in modern construction and insulation methods

According to Erica Stark, Executive Director of the National Hemp Association (NHA), hempcrete is not structural on its own unless used in prefabricated blocks. “These prefabricated blocks have a bioplastic structure built into them, which makes them look like Lego bricks and allows them to be stacked.” The most common applications involve either retrofitting hempcrete insulation into existing buildings or using it in new construction by packing it into a wooden frame. In this approach, the timber frame provides structural support while the hempcrete fills the walls. Whether applied as insulation or as prefabricated blocks, the material itself remains essentially the same, with differences mainly related to prefabrication and internal reinforcement.

Environmental benefits of using hempcrete for green building projects

Advocates of hemp emphasize its environmental and sustainability benefits, and hempcrete strongly reflects these qualities. “It can regulate temperature and humidity, reducing fossil fuel inputs for heating and cooling. It’s a great insulator, but at the same time it’s breathable, which results in superior indoor air quality,” Stark explains. Many modern homes rely on insulation materials such as fiberglass, which often compromise air circulation and indoor air quality. Hempcrete allows air movement while maintaining thermal efficiency and is naturally resistant to mold, mildew, and pests.

Hempcrete is approximately eight times lighter than traditional concrete, which leads to further environmental advantages. Its reduced weight lowers transportation energy demands and emissions. In addition, construction using hempcrete often eliminates the need for heavy machinery and large-scale lifting equipment, further reducing pollution during the building process.

How hempcrete contributes to carbon sequestration and climate solutions

One of hempcrete’s most significant benefits is its ability to sequester carbon dioxide. “For all of our technological advancements, sometimes simpler is better. Going back to things that were proven in the past still makes sense in the modern world,” Stark says. Hemp absorbs CO₂ at multiple stages of its lifecycle. One hectare of industrial hemp can sequester approximately 15 tons of carbon dioxide, and hempcrete continues to absorb CO₂ for up to 100 years after installation. “You get the benefit during cultivation, production, construction, and then ongoing sequestration throughout the building’s lifespan.” As a result, hempcrete structures can be carbon neutral or even carbon negative over time.

Lime extraction and the carbon footprint of the hempcrete binder

The main environmental drawback of hempcrete lies in the extraction and processing of lime, the binding agent. “There is a carbon footprint associated with extracting lime, and some binders even use Portland cement,” Stark acknowledges. However, studies show that the carbon sequestration benefits of hempcrete far exceed the emissions generated during binder production, resulting in an overall positive environmental balance. Despite assumptions that large construction industries might resist hemp-based materials, Stark notes that this has not occurred on a large scale. “There’s a notion that behemoth industries would push back, but I haven’t seen that happen in the real world.” Regulatory delays and local resistance remain the primary obstacles.

Traditional construction techniques using hempcrete and timber frames

Hempcrete is not positioned as a replacement for existing industries but rather as an enhancement. “We’re not talking about disrupting industries—we’re talking about making existing products more sustainable.” Because hempcrete is typically used with timber frames, it does not threaten the wood industry. Its greatest potential impact lies in the insulation sector, particularly fiberglass. As demand for sustainable materials grows, hemp bast fiber could increasingly be integrated into conventional insulation manufacturing.

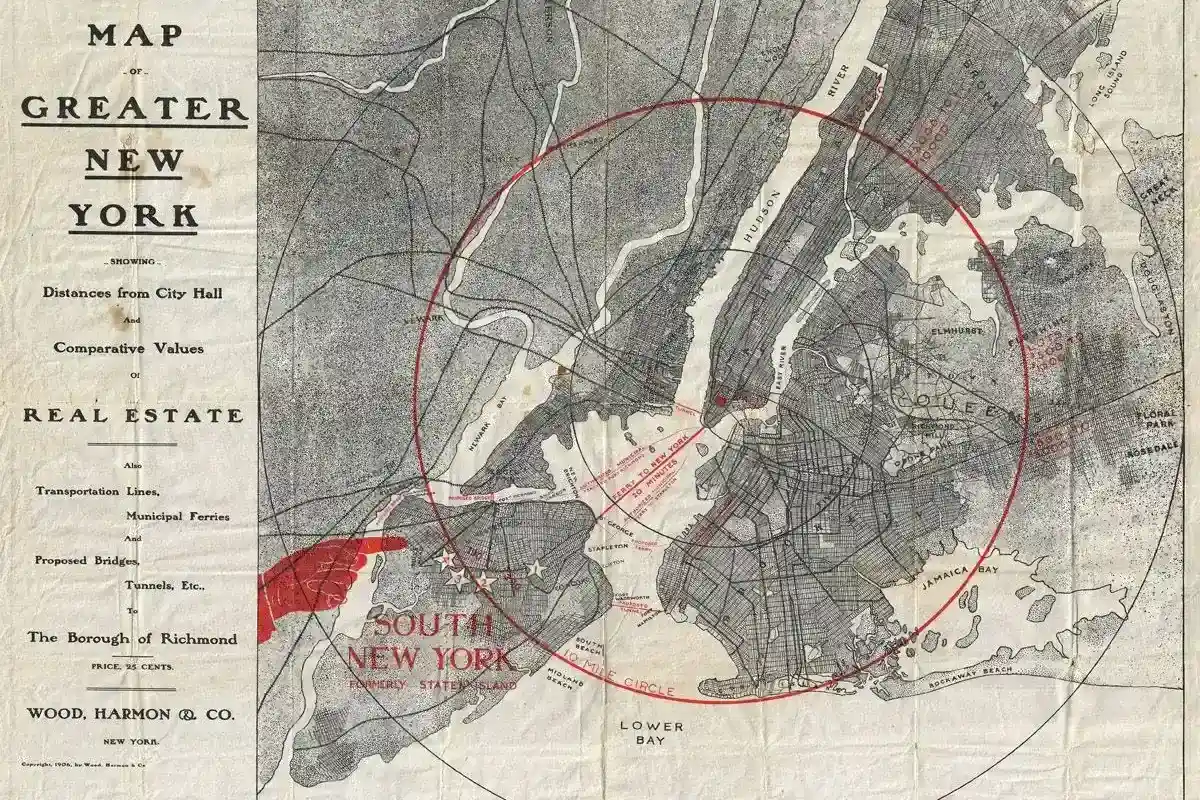

Why hempcrete remains relatively unknown despite ancient origins

Hemp-based construction dates back to Roman times. A mortar bridge in France built in the 6th century using hemp still stands today. Despite these ancient origins, modern research and development of hempcrete is relatively recent. Although hemp was federally legalized in the United States in 2018, the industry is still rebuilding the infrastructure needed for widespread adoption. “For years, the only option was importing raw material from Europe, which was cost-prohibitive. Even now, we lack sufficient domestic processing capacity to make it competitive,” Stark explains.

The evolving status of building codes and hempcrete regulation in the US

Another major barrier has been the lack of standardized building codes. “We know it’s safe. The challenge is getting inspectors who have never seen hempcrete to approve its use,” Stark says. Progress is underway. In 2022, ASTM International released the first standard for hempcrete insulation, and in 2023 the International Code Council approved its inclusion in the 2024 International Residential Code. “These standards allow architects and inspectors to recognize hempcrete as a legitimate material instead of something unfamiliar.”

Comparing hempcrete with concrete in terms of cost and competitiveness

Hempcrete remains more expensive than traditional concrete, though the gap is gradually narrowing thanks to improvements in prefabrication, regional supply chains, and increasing demand. “To be commercially viable at scale, costs need to align more closely with conventional materials.” The lack of infrastructure and standardized production remains the main reason for limited adoption, but ongoing development could significantly reduce both cost and carbon footprint.

Prefab hempcrete blocks vs. onsite installation

Using prefabricated hempcrete blocks reduces construction time since the blocks arrive fully cured, but transportation costs are higher due to their weight. Onsite installation lowers transport emissions but requires extended curing time before exterior cladding can be applied. Current research focuses on prefabricated panels rather than blocks to improve efficiency. Despite recent growth, most decortication facilities can process only about five tons of hemp per hour, far below industrial demand.

Building regional infrastructure to support cost-effective hempcrete use

To reduce costs and emissions, regional processing facilities are essential. “Ideally, decortication and panel manufacturing should be located within fifty miles of where the hemp is grown,” Stark notes. Localized infrastructure would significantly improve both economic and environmental performance.

The future of hempcrete: a realistic path toward large-scale adoption

Hemp’s versatility makes it suitable for multiple industries, but scaling cultivation remains a challenge. Stark suggests integrating hemp into existing crop rotations rather than replacing major crops. “Converting just five percent of U.S. corn and soy acreage—about eight million acres—would be enough without disrupting existing agriculture.” Given the government subsidies already supporting corn production, similar policies could accelerate hemp’s adoption.

About the National Hemp Association and its mission for hemp’s future

The National Hemp Association works to support the growth and development of the industrial hemp industry by educating stakeholders, fostering collaboration, and building awareness of hemp’s benefits. It represents farmers, manufacturers, processors, and startups across the hemp value chain.