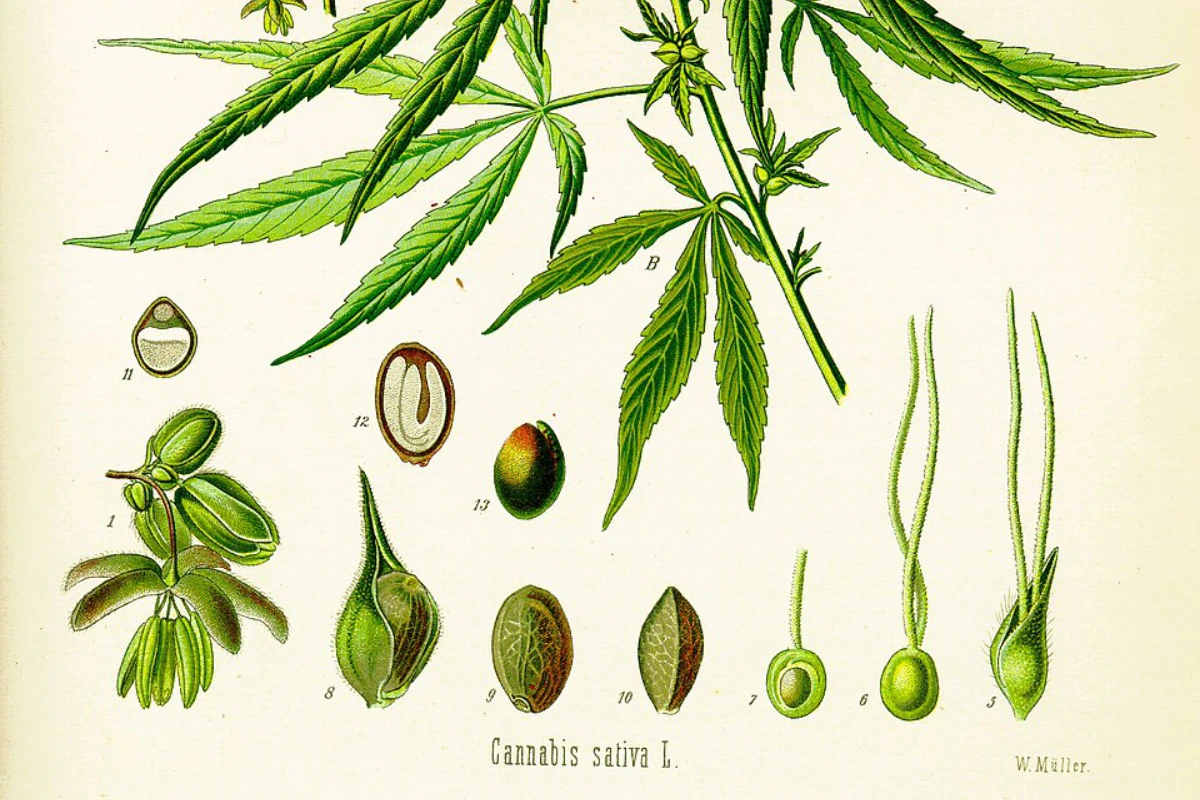

Natural binders: magnesium and potato starch make hemp products fully circular

Dutch designer and professor Jack Brandsma explains how the combination of hemp, water and natural binders allow the creation of a robust cement-like material

The binding material: adhesives from natural resources

Long before synthetic bonding agents from petro-chemicals and synthetic resins were developed, adhesives from renewable resources—such as casein and protein— were already in use. They all work as adhesive, which is any substance that is capable of holding materials together in a functional manner by surface attachment that resists separation.

In the manufacturing of wood-based panels with conventional synthetic resins, bonding agents cause up to more than twenty percent of the total production costs. Nowadays, those same costs for conventional crude-oil-based binders are on a rise. For these reasons, binders from renewable resources regained attraction as alternative bonding agents.

Fibers and binders: once they’re together, it’s difficult to tell them apart

Fibers are often used in combination with a binder, like glass fiber, that goes with polyester or epoxy, to enhance the material strength. They need each other: polyester without glass fiber is brittle, glass fiber without polyester is too flexible. A rigid construction needs both.

One of the biggest issues that interest not only the work in construction but also the fashion industry is that when you combine the fiber with a binding material, they become one, and it’s difficult to tell them apart.

Designing in the Dutch context: self-production and working with hemp

In the Dutch context, where designers could not count on a network of small and medium-sized enterprises, self-production became a mandatory path. Dutch self-producer designers are also the result of a school education system which, in the field of design disciplines, does not disdain manual skills and encourages students to professionally implement their ideas.

On his work with IHOG (Innovatie Hub Oost-Groningen), a cooperation of three companies based in the Province of Groningen (HempFlax, Nedmag and Avebe), Lecturer and Researcher at Academy Minerva Jack Brandsma and students are working with IHOG’s materials leading to a range of samples and prototypes.

HempFlex collaboration with BMW

«We started working with HempFlex in 2018. They produce felt made from hemp. At first we got the knowledge of the material and after one year we started to think about applying the natural binders for the designs».

HempFlex has been working with BMW to make interior panels for the automotive industry. Hemp is applied in the door panels instead of glass fibers. In that sense, the combination of a synthetic binder, a thermoplastic material, and hemp would actually make a rigid panel that is half natural and half synthetic. «I thought that they would replace glass fiber with hemp for green reasons. But it was not the case: it was for weight reasons because hemp is lighter. But then again you have these two fibers that once united become inseparable. So from our point of view looking at binders is crucial».

Natural binders in combination with hemp

Brandsma and his students started to work with magnesium oxychloride and potato starch because HempFlex provided those materials by joining forces with other two companies. He made clear that they don’t often mix magnesium with potato starch. It’s either one or the other. They have different properties and they are dedicated to different uses.

«The magnesium we use is the combination of two components: one is magnesium salt, oxide, and the other is magnesium chloride that looks like a white powder. The result is oxychloride, also called sorel cement. Sorel was a chemist that found out that you can make cement with magnesium as well. We got some information from the laboratory on the proportions and we started to experiment».

Magnesium oxychloride

In addition to that, magnesium chloride and magnesium oxide are mixed with water: «If I had a bucket full of this fluid material and water you could just put the felt made with hemp fibers in it and it would be completely soaked with this material. The good part of hemp is that it can absorb water well».

Brandsma explained that by clamping this mixture between two wooden tables, while putting pressure on it, the material will have the same kind of hardening of cement. It would take about 24 hours to become rigid enough to go ahead and get rid of the moisture left.

Potato starch is a friendlier binder than glue

Potato starch is known for being used as glue for wallpapers. It comes as a dry substance in a package that needs to be mixed with water in order to be activated. It will then become like jelly glue. A lot of potatoes are used not for consumption but for all kinds of applications: for example, to improve the foam on beer, but also for construction, diluted with glue for gluing ceramic tiles on the wall.

«The magnesium has a more fluid consistency», explained Brandsma. «With the potato starch you can get a result that is quite similar to papier mâché, so it’s nice to work it with your hands».

In terms of properties, Brandsma explained the main difference between one binder and the other: «Half of the magnesium is salt so it can be aggressive to everything that is made out of metal. In my workshop I have been working with magnesium and some machines have reacted to it. Potato starch is a friendlier binder».

The designing phase for Brandsma

When it comes to replacing materials we need to find a natural material that is equally good in terms of performance. There are a lot of things that the natural material, which comes in as a replacement, has to be capable of. Since synthetics have had years to develop, they still are the best choice for a lot of design projects.

«I wanted to motivate my students to develop an application for natural fibers and how they can be used. Shape wise they were possible, strength wise they were not so good. I came across the designs of Willy Guhl 1954, a Swiss architect that started designing with company Eternit, famous for making wood panels out of cement with asbestos fiber, which was good to bind cement with, although dangerous. I tried to challenge my group to come up with ways to make equally rigid and strong projects using a combination of natural materials».

Brandsma said that he can see the material being applied to furniture. He made the example of some tiles in the ceiling in his studio made of hemp, as an idea they are already trying to bring close to the industry. Unlike polyester, they are good at absorbing moisture from the air and to give back humidity on drier air periods.

Biodegradability vs. durability

All the binders Brandsma and his team work with are sensitive to moisture. That’s also a good sign because it means that over time, it will biodegrade. The question is how fast it is going to biodegrade and under what circumstances.

One product of his work is a table entirely made of hemp and potato starch: «you would want to be able to get it wet to clean it once in a while».

He made sure to highlight that the one thing that needs to be truly taken into consideration, is that we throw too much furniture away, and too often. The whole idea of constantly consuming new stuff is wrong: it’s not that we don’t need new stuff, it’s rather we are promoted to buy new stuff.

The impact on the environment and the end of life

«Why would I bother too much about biodegradability if I made a table that will be with me my whole life? And maybe after I pass away, I will give it to someone else. We build houses for thirty years instead of building them for a hundred years. We accepted a way of living in a system that is all about consumption and newness. It is complicated to go around that. It is more interesting to look at it as a way to start looking at available possibilities around us».

How can we make better use of everything we already have? Every manufacturer is worried about the impact on the environment not only in the process but also regarding the end of life. Especially for designers of this time: they are becoming inventors. Designers graduate every year from designing school and they have to make a living by making products. Sometimes they are not necessary but because the designers need to produce, new things are invented for the markets and not out of need. We need to look at other applications of the materials we already know and push a shift in education.

Jack Brandsma

Designer and education professional at Een Paar Ontwerpers v.o.f. and Academie Minerva Groningen, Netherlands. In his work, he revaluated the use of natural binders in combination with hemp fibers.