From cotton farming in Texas to manufacturing in Bangladesh and on to disposal and donations in Ghana, the whole terrifying life cycle of clothing

The dark side of fashion recounted by a pair of jeans

Maxine Bédat inquiry starts from a pair of jeans. A garment commonly used in much of the world and a symbol of the globalization of the fashion system itself, the writer explains when discussing the choice of this clothing piece in her book. Unraveled: The Life and Death of a Garment aims to cover this item’s journey through the entire supply chain and all the way to its disposal.

The ultimate goal, Bédat confirms, is the possibility of making the reader understand how the fashion industry is full of black holes. By the end of the book, the writer says, it is clear that the human and environmental cost of these productions is greater than the profits generated. «I chose a pair of jeans because it is a sort of universal garment that comes across gender, geography, socioeconomic status», Bédat explains.

She also recalls the historical role of the garment itself, which is often considered an American invention but jeans fabric was made up in Genoa and denim comes from Nimes in France. «Moreover jeans are made of cotton, and when you tell the story of cotton, particularly in the United States, you also talk about slavery and global trade. This very universal garment also has a deep story to tell», the writer concludes.

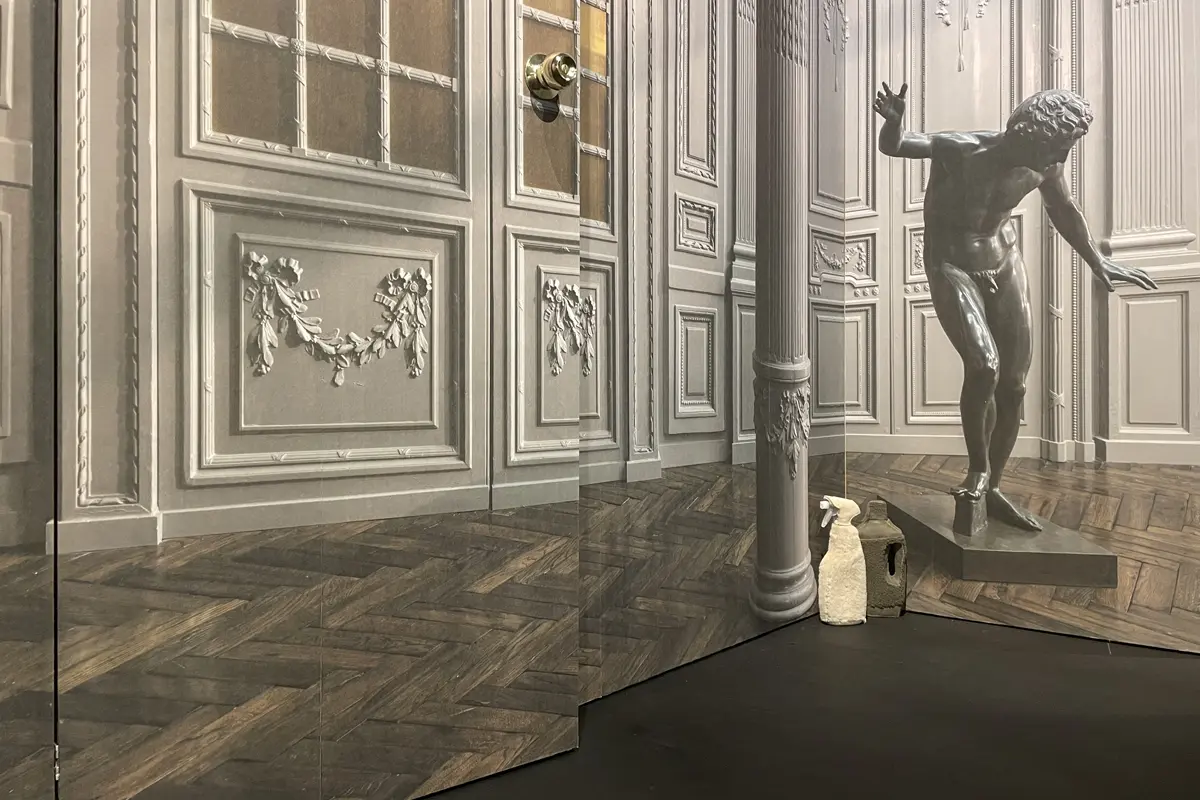

Unraveled: The Life and Death of a Garment

Using denim is also explanatory of today’s supply chain model. Being among the common worn garments allows one to understand through its massive production each manufacturing step and its method of execution today. The entire journey of the garment, from where it is crafted to how it reaches the different steps is investigated in Bédat’s book.

It starts from the material and cotton fields in Texas to explore how it is grown and the history of this practice but also the conversion to the organic option. From here where cotton is baled it moves to China where much of the fabric is produced today, she explains. From cleaning to dyeing and finishing the entire process of the fabric is explained. She then continues her journey to Bangladesh and Sri Lanka and here the final item is manufactured. In this step, the focus is also on the impact of the work mode on the individuals.

The following chapter is set inside the Amazon distribution center because of the relevance of online shopping in recent years. From here the book begins to focus on the end consumer, returning again to the United States and investigating the relationship with clothing and why it has evolved in this way, along with an analysis of marketing strategies.

Starting from cotton: the focus on Texas fields

The unique aspect of being able to follow the step-by-step production stages of a garment is to understand up close where what people wear comes from. Starting in Texas, Bédat traces the steps that made the U.S. become the dominant player from the contact with farmers. Cultivation techniques, the connection with the earth and the soil, and their subordination to climate and weather phenomena are some of the aspects learned on site.

«When we think about conventional cotton today we refer to that which is chemical and intensively produced. And that has become the standard for a generation, but earlier farming methods were very different», she points out. What emerges from this trend are a number of problems related to workers physically dealing with these pesticides and the health of the soil itself.

She points out how this component is often overlooked when talking about environmental impact and how this process forces people to continue to use increasing amounts of chemicals to get the product. The soil consequently loses its properties such as absorbing carbon or retaining water giving way to continuous disasters such as floodings.

Textile impact and the insufficient work of the labels

The issue of organic cotton cultivation seems clear with respect to a job that is already unstable as that of the farmer. Above all, the switch to become a certified organic cotton field is at the expense of the same without any policy or help coming from the government. The writer also points out that it takes three years for the cotton produced to be declared organic. The path requires a significant economic and soil restoration commitment, which is why farm goals should be aligned with government ones, adds Bédat.

Moreover, at the level of materials used in clothing production, transparency towards the consumer is still a distant aspect. Labels cannot in any way be comprehensive with regard to information about the individual garment. «In the U.S. the requirement for labels is to have information about the type of material and where it is made, which is a rough figure considering that only one country is included, but as you read in the book rarely is a garment entirely made in one country», Bédat says.

Regarding the material there is a lack of knowledge even on the part of the consumer, she points out, many are unaware that polyester is made from plastics for example. Other information to be implemented in the labels could be the chemicals used and the environmental impact of the product, she believes.

China, the hotspot of apparel production carbon emissions

The rough fiber product has been already made and the following step takes place in China. The parallel done by Bédat between curly hair and this material emphasizes the energy and strength needed to work it. The transition to a straight and dyed material is then obtained in the same area.

High levels of heat are required for the fiber to maintain these properties and in particular to change in color, the writer further points out. All this production relies on the use of a series of machines arranged side by side in these factories in China. And it is in this particular country that coal energy is still being employed at a rate that forces more and more garments to be produced.

That is why, Bédat explains, the step that makes fibers into a fabric represents one of the biggest hotspots in carbon emissions when it comes to apparel manufacturing. «Seventy-six percent of the climate impact of our clothing is happening over there», she highlights.

The inhumane production assembly line in Bangladesh

Bangladesh, Bédat explains, is a massive market for clothing production. About eighty percent of their global export is apparel and the cutting and sewing work is done by people using individual machines and for the most part by women, the writer is keen to point out. In contrast here what is striking inside the factories is the human assembly line put in place for manufacturing.

Every single component and step is performed by these individuals arranged one behind the other who have to pass the garment to each other in the shortest time possible so that it can be completed. Each person in that production line is engineered, the writer comments, so that everybody is working in locksteps. Everyone has a sort of timing in which they have to perform that motion in a concatenation of alienating movements. The intensity of the work can be perceived from the individual experiences that Bédat has collected in her book.

All these workers can think about and live by is: be fast, don’t make mistakes, you can’t get up to go to the bathroom or stop to rest or slow down. Also the moment this chain gets stuck a red light comes on the floor to signal the irregularity of operation. They describe it as prison work, the writer continues, and during the day they have no time to think about anything they declare, keep going and don’t make a mistake is the only thought they can have.

Sri Lanka case, another reminder of slavery in the garment industry

In Sri Lanka the production chain is similar to the Bangladeshi one, but the work here is subject to immigrant exploitation. Several women who come from the north of the country try to relocate to find greater stability and economic well-being in the other part of the same. Here, however, they often run the risk of ending up as prostitutes. Among those interviewed by the writer, one of the women had been told that she would work in garment production, but after she was obliged to do the sex worker. Another aspect from Sri Lanka that highlights the exploitation of labor within the industry. It is as if the days when slaves in America were sent to the cotton fields never passed, comments Bédat. This form of slavery in garment production seems only to have evolved to a form that today, in 2022, can only be described as terrifying.

The necessity to have Fashion Seasons

Starting with the construction of the idea of the fashion system affecting consumption habits, one cannot help to discuss the question of seasons. Bédat points out that there is no human reason for their creation; rather, the driver of seasonality is purely economic. It all began with the French, comments the writer, who studied while writing the book and identified in this conception a mode and technique of economic accretion that is not indifferent.

That is also what we find today in the evolution of that strategy: fashion months and the system of production and sales. The capitalist system that marks a company’s growth models today does not allow them to focus on a long-term definition of their strategies. This would make them understand the need to ensure fair jobs in tasks and pay by guaranteeing, for example, minimum wage. But what the financial market pushes upon is the rating of companies based on their ability to generate profits in a short term, the writer emphasizes.

Nowadays companies that want to put a good effort in the industry start with a competitive disadvantage, says Bédat, just because of the presence of this economic system. Another aspect investigated in the book include social media and their influence on the younger generation. The key role of some media personalities and the facilitation of the buying process through Instagram and Tik Tok channels.

Investigation on sustainable economic and production models

The solutions are different and multiple with little possibility of finding a universal one to apply to all companies, all countries and every step of production. One relevant key to addressing the critical issues highlighted is the establishment of precise laws. This would mark an effective boundary, explains Bédat between those who already apply them and operate within the industry and have to adapt and those who can have easier access because of the fundamentals of their brand.

These are, for example, those smaller companies that focus on regenerative research or biobased textiles. From agriculture and new available technologies for growing, the whole system needs to be rethought from this perspective, the writer reiterates. Then there are the rental companies and again the brands that produce with a view to wearing the garment for as many years as possible thanks to new fibers technologies.

Policies can have a huge influence on the fashion industry, explains Bédat who has a legal background and is working on a legal development in the US. California for example, she continues, has imposed standards on those who want to sell in its market, and so many companies have changed the way they produce so they don’t stop selling there.

«It is the law that kick-starts and makes a lot of progress in this phase of the industry. As in New York we are starting setting standards, from the labor to the chemical ones», Bédat concludes. Laws in this way feel a system of guidelines for each brand to follow, and ideally, as suppliers are shared by several brands, it would only take one of them to start doing business in this way to drive the system.