A politicized textile with the ability to transform the planet, but not without challenges. The future of hemp through conversation with Majdouline M’saad and Robert Jungmann

Hemp positive characteristics

A carbon warrior, a phytoremediation plant and an eco-friendly alternative to cotton; hemp has these positive characteristics, yet the politicization of the plant as well as the lack of certification within the textile industry has resulted in challenges looming over its success. As hemp becomes more and more industrialized, questions and debates arise about the plant within the industry. Majdouline m’Saad, Senior Product Specialist of New Guards Group (NGG), who also takes care of all certificates for all brands of the group sits down with Robert Jungmann to discuss the positive and negative aspects of the industrialisation of Hemp, the alternatives within the textile industry and the way forward. Ms. m’Saad leads the strategy and execution in supply chain and production of the sustainability actions within NGG brands, where they have a portfolio of nine brands at the moment. Mr. Robert Jungmann started a company called Jungmaven in the 1990’s. He has always been focused on industrial hemp and has been directly involved in policy changes surrounding hemp within the United States.

SE I would like to start off by asking both of your perspectives on how you see the current landscape of innovative materials, more specifically on hemp.

MM I am intrigued by this awakening that is happening in the industry. Sometimes it is mind blowing what we can do to create new materials. There is so much to discover and there is a bigger responsibility for us, because it also means a lot of first case scenarios where materials are born from new fibers that we don’t have experience with; we don’t have a life-cycle assessment from before that can guide us on whether they have more benefits for people, animals or the planet. There is a bigger responsibility to vet these materials, but at the same time it is an impactful movement. In the last five to ten years sitting down with scientists, material engi- neers, material designers, merchandisers and buyers, influencing what materials can be and also ultimately the consumption of these materials. We have the power to influence consumer behavior, which for me is the most important thing to do at the moment, in order to achieve a more sustainable way of living. I think hemp is one of the most interesting plants out there. Just the fact that you can use every part of the plant; it has so much market value. Hemp for me, from a sustainability perspective and especially from an environmental perspective, has a higher yield, consuming less water than conventional cotton; there is so much potential if we are talking about organic hemp; we are not using any pesticides or chemicals. I am intrigued to talk about this especially when it comes to conversations and Robert, you must know about circularity and the fact that it is a zero crop.

Giving activewear a change – blending hemp with other fabrics

It is a challenging industry to be in to help create change and that’s why I wanted to get into it. Starting back in 1993, there weren’t that many options. We had hemp canvas and twill. We made backpacks and we tried to make pants – they didn’t work so well. It was constantly im- proving and making changes to the hemp fabric. Today we have knit fabric; we didn’t have that in 1993. I think it was in 1996 when I first saw the first knit fabric and it was a t-shirt that you could see through; it was not well knit. It has come a long way, now we’re beginning to blend hemp with some merino wool, some organic cotton and even lycra. We’re giving activewear a chance and even though it is 30% hemp, at least there is some hemp in there. We always said we have hemp t-shirts, but the fact is that most of it is blended with organic cotton and we often get asked why we have cotton there. It brings a lot of body to the shirts, but the new 100% hemp shirts are innovative. We are also beginning to knit more in the United States and that is helping us to try different combinations and weights of fabric. We were limited to what was available out there, but now we are importing the yarn. We are trying to enter the activewear market and during the first round the biker shorts were basically see through. We knew we had to step it up and make it a little bit thicker. These are the things that the innovative fabrics are helping to deliver; the product that works and what people gravitate towards and what people want more of.

SE New Guards Group brings together creative fashion houses who have reshaped the fashion scene through creative innovation. How does this unification ensure a new level of transparency for the future of craftsmanship in textiles?

MM The biggest issue in this industry for everybody now is data and how much data can be quite fragmented and opaque to get. It is challenging to get a sense of truth about where something started and where it ends. We know at some point where we intervene, who our suppliers are and how they operate because we control them and we check them, but anything that happens before; like raw level materials, extraction can be difficult. If our brands were to operate by themselves, if they were a fragmented structure, we wouldn’t be able to align them and gather them under one umbrella and really implement our policies. Most of all, not only the policies or not only the things that we ask our suppliers and vendors to do for us but also what we do as a group. We have a consolidated vision with FarFetch and what our code of ethics is, what we look for in a vendor and how we vet them before implementing them within our supply chains. There is less risk in the sense that if a brand were by itself, we would have to start from the beginning and people in the fastness of things would work with anybody to make a product happen. When you are a part of a group there is much more structure and much more control, which is what we need. If only this means centralizing supply chains, which is key to building stronger, and longer partnerships with them and ultimately fewer, but more solid partnerships. I believe in cohesive work with the people that we collaborate with. These people not only work for us, they work with us. The fewer suppliers you have, the more opportunities you have to repeat the process and to form that human relationship with them and ultimately achieve aligned goals. Brands can set as many goals as they want in terms of climate change and even material sourcing, but ultimately if their supply chains are not aligned with those goals, we’re not going to achieve anything. Our impact on the total is so much less than our manufacturer or our materials have. Centralizing supply chains, aligning policies as well as a single origin so that you have a sense of solidity that comes with NGG.

Using hemp on a more industrial scale

SE There isn’t much out there which links the New Guards Group and the discussion on hemp. How much are the two linked? Are the member brands looking into using the material on a more industrial scale?

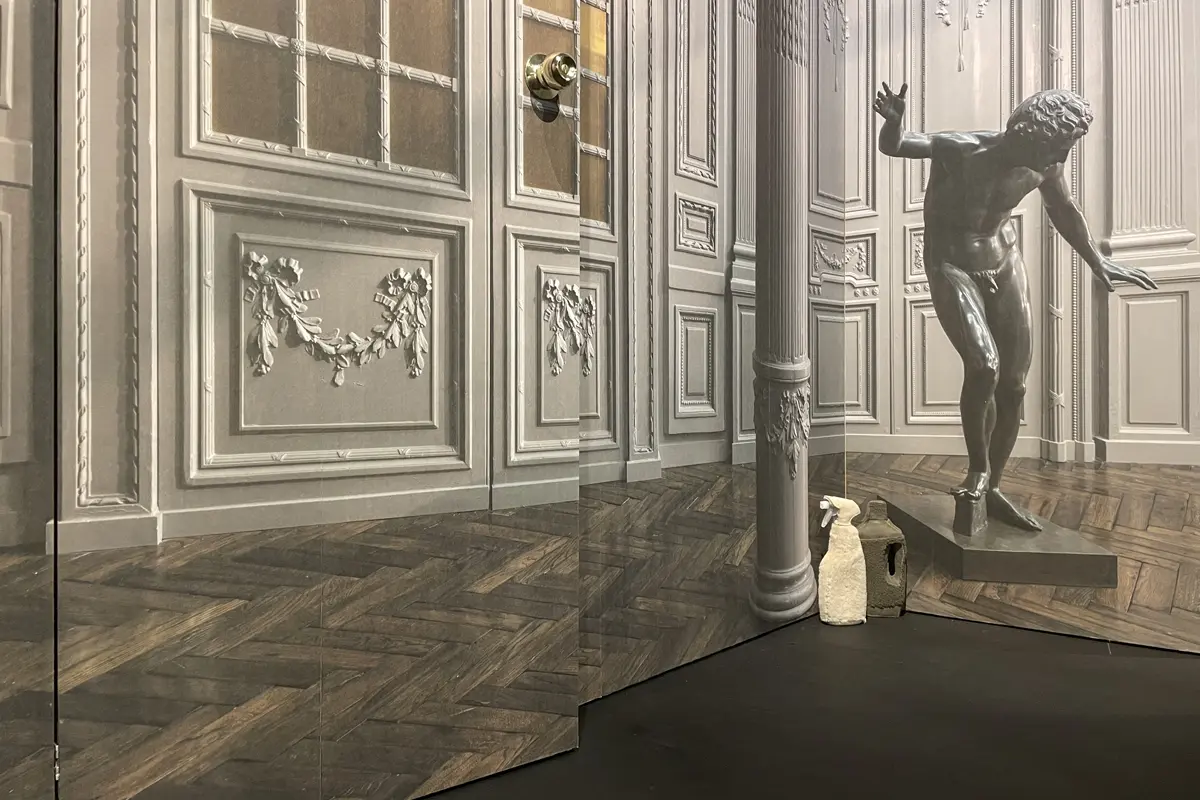

MM NNG started its sustainability reshape about three to four years ago. We are not really about disclosing what we do, we have been working internally on so many exciting projects. One of them being a project on denim, and as Robert said; pants are quite a difficult category. We have worked here and there with hemp on some bags or accessories, but it was always some limited edition drop that we did. The material itself I believe has had bad PR and misrepre-sentation throughout the years; it can work for certain collections, but not for everything.

We spoke with our teams and analyzed what the most problematic category is that we have; from an environmental perspective and from a product perspective, with the conclusion being denim. We sell high percentages of denim and we have some stable partners like Candiani Mill. What we did with them for the last six to eight month was developing a new quality of textile; it is a mix of organic fabric, hemp and a new biodegradable organic rubber instead of a fossil fuel based elastane. This is a stretch fabric, but it is going to be applied to menswear and workwear in particular. There are so many different perspectives on this, on one hand we are tackling the fossil fuel issue. If we want to keep the idea of biocompatibility, which is what draws us to hemp, we cannot mix it with any synthetic textiles. We worked with organic rubber and organic cotton in minor percentages, the hemp fiber is the majority in this fabric. The collaboration with SE Candiani, which is already one of the most green mills in the world, speaks for itself. We looked at this on every level; how the denim was washed, the fiber and even the end-of-life cycle. If this denim were to end up in a landfill one day, it can biodegrade and fertilize the soil where it MM is. This is one of the ways we have approached hemp in an innovative way and not just making a t-shirt from the fabric. I always want to have a twist on what we do and that is what we are known for.

RJ I think it is relevant and positive to see an improvement of denim coming out of the market. One of our goals at Jungmaven is to be as transparent as possible. We’re always educating. Hemp was illegal until 2018 in the US and our main goal was to get this resource utilized in the US again. We educate and display the benefits of hemp. We are attempting to raise the bar for the industry, to create a product that people crave so much that they disregard the idea of having synthetics and don’t want to put it on their skin anymore. The benefits of the textile are prevalent through our marketing and website; informing consumers of the benefits, the natural RJ and fiber reactive dyes that we use. What is happening right now in China in the Xinjiang region has resulted in a standardization process being brought into the US. It sustains a sense of transparency so that it is clear where the hemp or cotton is originated from. This could be the future of where this industry might be going; from farm to on your back. Hemp is not certified organic at the moment, but there are certifications coming. I always say that if you are growing some very toxic product on your land, you would want to grow c. Since my time in college when I SE started learning about hemp, it was not even 1% of the fashion industry, so it has come a long way. It’s rewarding to see bigger companies get more into it, that was our ultimate goal.

The manifolds uses of hemp and benefits on health and negative sides

MM What you were saying about the detoxifying of soil because this plant is intriguing. The CBD RJ oil also treats cancer and there are benefits that are documented and are scientifically proven; also on health.

RJ It also uses so little water. I have been in this industry almost 30 years, but I had never been MM to a hemp farm until the summer of 2022; I went to a farm in San Joaquin Valley in California. There were 20ft tall hemp plants, which emulated a bamboo jungle, that grew that tall in four months. It was the only green area within miles. Hemp uses minimal water while converting C02 into oxygen. It is a plant that can help us find balance on this planet as there is so much C02 in the atmosphere and we need to be converting that into oxygen.

SE Hemp has many benefits, all of which are highly talked about. What about the negative sides? Are these known and hidden or are there simply very few issues with its industrialisation?

RJ Any textile in the fashion industry has its challenges. The creating and the growing of it, the processing and the shipping, storage; the list goes on. The closer you can do it the better; that is one of the things that is stated with hemp, you want everything to be happening within a 100 mile radius. At the moment we are importing containers of yarn from China and knitting it in LA, but the goal would be if we were growing it in the San Joaquin Valley just 100 miles away. Some of the challenges that we specifically are facing is the fact that we’re not growing it here in the US. We are dependent on what is done elsewhere. Another challenge is cleaning the hemp. More natural enzymes are being used now, but historically it was a process that involved large quantities of water and stripping down the plant, which sees it falling apart and then you pull the fibers off. Afterwards it has to be cleaned so this process historically might not have been the most environmentally friendly. As the fashion industry progressed more into this system and demanded a more environmentally friendly outcome, changes have occurred. I think there are challenges, but the benefits far outweigh them.

Chemical retting and bleaching are some of the biggest impacts, as well as dyeing. Unfortunately designers still need to do a lot of work in this sense, it is not only on consumers and how they choose their clothes. Creators and people who have creativity and can influence a sense of taste, sometimes due to ignorance and not because of them not wanting to do something, but they might modify a hemp fiber by bleaching it or using caustic soda to create a special effect and that in effect ruins the hemp. There is this sense of misalignment and there needs to be a philosophy that cannot be broken. There are certain rules that need to be established. As someone who hails from Morocco, a country that produces a lot of hemp, I have seen first hand how many communities thrive off the benefits of this plant. Not only in the narcotic market, but I have seen how it can be socially beneficial to sustain entire communities and families. These people have extreme knowledge in treating this plant and creating products that range from narcotic drugs to things that are beneficial for our health. It is a highly politicized plant, with lobbies that control it. The social implications, especially on a production level with raw material extraction, while having its benefits, does not automatically disregard that working conditions oftentimes are not up to par. We need to avoid what happened with cotton and look at the circularity of the whole process.

Hemp as the overarching fiber of the fashion industry?

Whilst hemp production is relatively low compared to other fibers like cotton, will there ever come a time where we’ll look at hemp as the overarching fiber of the fashion industry?

The estimated land worldwide available for organic cotton is between 2-6%, yet everybody wants it. The math is clear and we cannot have organic cotton replace all the cotton that is being used. Recycled cotton has its own issues, even though it is beneficial sustainability wise, the fibers are shorter, smaller and break down easily. If we were very good at shifting consum- er behavior and breaking apart the bad PR that hemp has had, as well as the aesthetic that it comes with, it could be possible. From an aesthetic point of view there is always this distinctive look that comes with hemp products. There are certain archetypes that are behind certain textiles and the stigma around hemp should be broken. Creating co-existing fibers would be beneficial; wool/hemp or silk/hemp; there are several options that can be combined to achieve optimal performance while maintaining the optimisation of the fiber.

What is the risk of this happening with hemp?

Being concerned about how hemp grows within the industry reminds me of the book The Lorax. I had a professor that implied that instead of cutting down the forests for paper, industrial hemp could be grown. That was a moment of truth for me and when I learned the benefits of hemp as a textile. When considering the nutrients that hemp returns to the soil, compared to other plants like cotton, the difference is insurmountable. It is about more than sustainability and rather about how responsible you can be towards the earth and other human beings.

Like with any new and safe discovery of a material, commercialisation and societal consumption turns it into yet another unsustainable alternative for the future. What is the risk of this happening with hemp?

At the moment we don’t have to be concerned about that. I hope to live a long time, but I do not think that is going to happen in my lifetime. I would like to see it become a bigger player in the textile industry. A diversification is imperative. I remember ten years ago when I was wearing cashmere, I had no idea that it was harmful for the earth, but it is not cashmere itself. It is how these fabrics are treated and what is done with it. It comes down to being responsible. The thing that impacts it the most is fastness. This idea that we have to run fast, collection after collection, no time to sit down and think. If we slow down the people and actors and players that have power to change things, the industry can actually think, and not only do; because in doing so is where most mistakes are made.

The certifications that hemp fiber has to hold

With hemp being such a politicized textile, what certifications does hemp fiber have to hold? Are there standardization processes already put in place or does this aspect of hemp production need to diffuse more?

MM From my experience with this it is the organic certified hemp or OneCert.

RJ It is one of things still in its infancy stages with hemp, we’ve been asking for the GOTS certification. It is not there yet with the hemp industry. At Jungmaven we take swatches of everything and send it to get tested.

MM This is a key matter; I was reading the laws that will be enacted in Europe by the end of 2023 about transparency within brands and it has been relatively easy to bypass up until now, since there is so much fragmentation within the industry and different schemes of certifications that you can follow. It ultimately depends on your consumer as well, certain consumers are more concerned about less harmful chemicals, others might care more about the environment and as a result of this fragmentation brands can pick and choose what to focus on. The best approach are the certifications that cover both; less harmful for your health and the planet. As much as I don’t rely on or relish certification, it is the only way to substantiate future claims so that no brand can make false claims without going through a third party. For the hemp market to grow and to comply with the law in Europe, there would have to be third party schemes.

The future of hemp in the US

RJ In 1994 we started the Hemp Industry Association here in the US and the main goal was to certify that things are what they perceived to be. It is defunct now, but one of the main goals was to give hemp legality in the US.

SE On a geographical scale, where do you see the hemp trade flourishing the most in the near future and why?

MM I hope Europe. If it could become decentralized that would be beneficial. Most luxury brands are based in Europe and if it was closer to where the operations and the design is taking place, that would be beneficial. In a scenario where Europe would be the first continent to really be affected by climate change, My hope is that this would increase our consciousness about our health and needs so that cotton can be replaced by hemp and to include more hemp in our fashion diet. Possibly all these negative things that are happening in the world right now, could have the positive effect that the way we consume will change. Something is boiling inside the consciousness and this is the correct moment to send the messages to the masses.

RJ European hemp is rich and we enjoy working with it; I hope to see it grown in Europe, Asia and North America – everywhere to be honest. I see it happening in the Carolinas and LA in the US. It would make the most sense and it is where the textile industry is located. I am not sure whether the US would lead the way in terms of textiles, but there is movement towards the CBD and using hemp for building supplies. The more hemp in the ground, the better. I hope to see the textile and fashion industry help create awareness and teaching about what can be done with it.