Denim mills bring more sustainable innovation to the Première Vision trade show in Milan with biodegradable clothing and zero-waste dyeing techniques

Denim – a water-intensive fashion staple

A life cycle assessment (LCA) study by Levi Strauss & Co revealed that 3781 liters of water was utilized in the making of a single pair of Levi’s 501 jeans, back in 2015. Right from the growing of cotton fibre, to chemical dyeing and finishing processes, denim has always been a water-intensive fashion staple. While original denim jeans were made from pure cotton twill weaves, stretch denim and skinny jeans paved the way for blended textiles; in particular, elastane and polyester spandex composites.

This plasticity of denim made it a sizable contributor to microplastic pollution generated by textile waste. Research shows that in 2030, textile waste will be responsible for 2.2 million tons of microplastic pollution as opposed to 0.7 million tons in 2022. Denim mills and brands have been studying and practically implementing means to reduce pollution and wastage of resources – including dyeing techniques, recycling waste water, natural finishing methods etc.

Sustainable denim, the protagonist at Denim Première Vision in Milan

The two-day trade show dedicated to denim held its third edition in Milan late last November with a sixty five percent surge in attendees compared to 2021. Sixty seven exhibitors and fourteen brands and designers presented their newest attempts at making denim as green as possible.

«There is a different approach to eco-responsibility» says Fabio Adami Dalla Val, managing director of Première Vision. «Before, sustainable development was above all a marketing topic. Today, greenwashing no longer makes sense. The producers are much more concrete, they offer innovative solutions».

Among other brands and manufacturers exhibiting, Italian denim manufacturer, Pure Denim’s founder Luigi Caccia shared his stance on sustainable denim: «Stretch denim cannot biodegrade. Making durable and long-lasting jeans that one can pass to younger generations is more sustainable».

In this regard, Turkish producer Calik Denim has a contrary opinion. The manufacturer launched their unique product B210 in 2022: denim that dissolves into nature within 210 days. It was also presented at Denim Première Vision in Milan.

The issue of denim biodegradability, solved: B210 by Calik Denim

Current legislature does not dictate a certification process for compostable fabrics, but companies refer and adapt standards set for packaging, i.e to be considered biodegradable a fiber or material has to degrade ninety per cent in 180 days and no toxic substances should be released into the soil during the process.

Calik Denim’s product is a hybrid process combining yarn technology and finishing techniques. The unique solution can be applied to synthetic blend stretch denims as well, maintaining a success rate of ninety nine percent biodegradability in just 210 days. Advocating for circularity in the denim industry, Serhat Karaduman, CEO of Calik Denim says «Our long-term goal is to have all our fabrics with this feature. Currently we offer a fabric family under the B210 concept but this is an innovation that can be applied all Calik Denim fabrics».

Advocating for circularity in the denim industry

This fabric is made up of both recycled and virgin cotton along with eight percent recycled and biodegradable Lycra T400. Karudaman shared that B210 went through a series of testing and prototypes over a span of three years, as each test took 210 days or seven months to get results. The studies also revealed that soil toxicity was not an issue and fabrics degraded at a faster rate when treated, stone washed, bleached or simply laundered.

Interestingly, Karaduman alludes to the process being wasted on all-cotton denim: «In rigid, there is no special process we do to denim with 100 percent cotton content; it dissolves in about six months anyway».

Players in the biodegradable denim game

With conscious consumers making up for a sizable chunk of the market, with numbers on the rise, many global denim brands are pursuing sustainable solutions – from natural dyes to upcycled collections.

«Many global brands that are our customers, after seeing the test results of this B210 innovation, excitedly rolled up their sleeves to launch their collections in this technology to the market» shares Karaduman, revealing names such as Hugo Boss, Banana Republic, Kings of Indigo and Mavi as interested partakers.

Another denim player investing in biodegradability is Italian manufacturer Candiani Denim, who developed biodegradable stretch denim made of plant-based Coreva technology, back in 2019. Since its launch renowned names in the sustainable fashion landscape have launched collections in partnership, including Stella McCartney, LA-based brand Triarchy and Dutch brad Denham among others.

No longer a dearth of clean dyeing solutions

Indigo-dyeing, though touted as a natural technique is not entirely sustainable as it is typically water intensive and requires chemicals to ensure the dye fixes onto the yarn. But indigo no longer bears the brunt of denim dyeing’s environmental impact as many innovative solutions have come to light. Though the industry may be slow in adopting them, progress is afoot.

Pre-reduced liquid indigo (instead of powder) is far more sustainable albeit expensive, hence used by only fifteen percent denim mills worldwide. An alternative dye made from used shrimp shells from the leftover food industry is Kikotex; it claims reduced resource usage, seventy percent less chemicals, fifty percent less water and thirty percent less energy. Foam dyeing, a less water-intensive process is also being used by brands, such as Wrangler.

Waste and energy reduction

Wrangler’s FW19 collection launched with foam-dyed pieces that supposedly eliminated almost 100% of the water typically used in the indigo-dyeing processes. Foam is used to transfer dye onto yarns, thereby replacing water vats and chemical baths completely. Wrangler also confirmed that waste and energy was reduced by almost sixty percent in this technique.

At Milan’s Denim Première Vision last November, Pakistani manufacturer Chottani Denim Industries revived a century-old vegetable dyeing technique through manual block-printing using antique hand-carved molds created by local artisans.

Recycrom™ technology by Italian company Officina39

One of the most sustainable and innovative dyeing solutions, Recycrom™ is a trademarked technology by Italian company Officina39. They essentially turn textile waste into dye powders. The company claims it has created: «A revolutionary and sustainable way to transform textile waste into colored powder dyestuffs. By transforming textile waste into pigments, Recycrom™ is the gentlest dye in the industry».

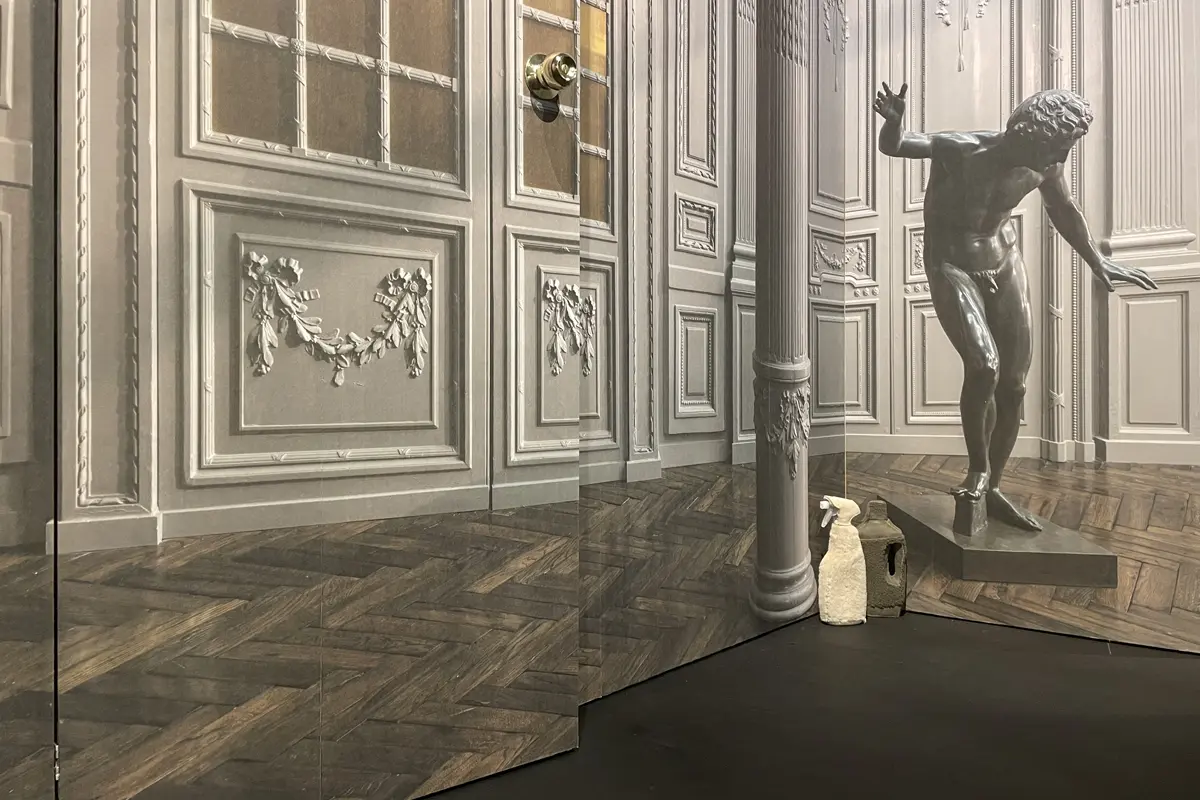

At the latest Denim Première Vision trade show in Milan, Officina39 showcased an entire range treated with Recycrom™. The pieces were tinted lilac and bright orange through different finishes including acid washing, marbling and distressed effects.

Broken down, Recycrom’s production process involves pulverizing waste textile fibers into a fine powder pigment that can be dyed onto fabrics and garments of cotton, wool, natural blends and nylon.

Recycrom™ is applied as a suspension, employing a waterless enzyme as opposed to a chemical solution. The company uses various dyeing techniques like dipping, spray, coating, screen printing and exhaustion dyeing. This ensures efficient cost management for the textile company as well as a reduced environmental impact.

«Denim is cyclic» – a future forecast

The next Denim Première Vision is scheduled for 31st May 2023 in Berlin. But Milan’s success has poised the city to land the title of Denim capital according to Adami. «Milan is the next capital for jeans» he predicts. While the trade show held in Milan in November saw many Italian and Turkish companies, the return of Chinese and Japanese names was positive. However producers from Pakistan and Bangladesh remained in retrograde as they continue to face a significant drop in volumes.

Adami explains «The denim market has always had cycles. But today these cycles have shortened». Further he confirms «Several manufacturers from Pakistan and Bangladesh did not participate in the show because they have a very low level of orders at the moment, especially from their American customers. Their production has dropped by 50%. It is the mass-market that is in crisis, because the stores are full and sales are falling. In addition, there are supply problems».

Meanwhile, in Turkey, the denim industry has observed a momentum due to the shift in production demand from Asia, after the Covid-19 crisis to the supply chain. One of the country’s biggest denim mills has also committed to becoming an innovation hub for sustainable denim, with the latest launch of their biodegradable technology, B210. In a study conducted by Première Vision in April 2022, this is also one of the reasons cited under purchase decision criteria among others like comfort, price and style.

Denim Première Vision

A roving event dedicated to contemporary denim narrative. It is a trade show that includes denim mills (weavers, manufacturers, producers) and responsible denim brands from across the world.