Italian companies fight marine pollution by giving new life to discarded fishing gear, joining hands with Prada to transform recycled nylon into high fashion

Italian Companies Team Up to Combat Marine Contamination with Sustainable Fashion

Marine contamination with plastic debris is an ongoing environmental problem, but a number of Italian companies are coming together to promote change. With a circular approach, Healthy Seas, an NGO based in Milan, combs the sea collecting discarded fishing gear. It then passes on the litter to Aquafil, a leader in the revolution of the textile sector that seeks to promote more sustainable processes within the fashion industry.

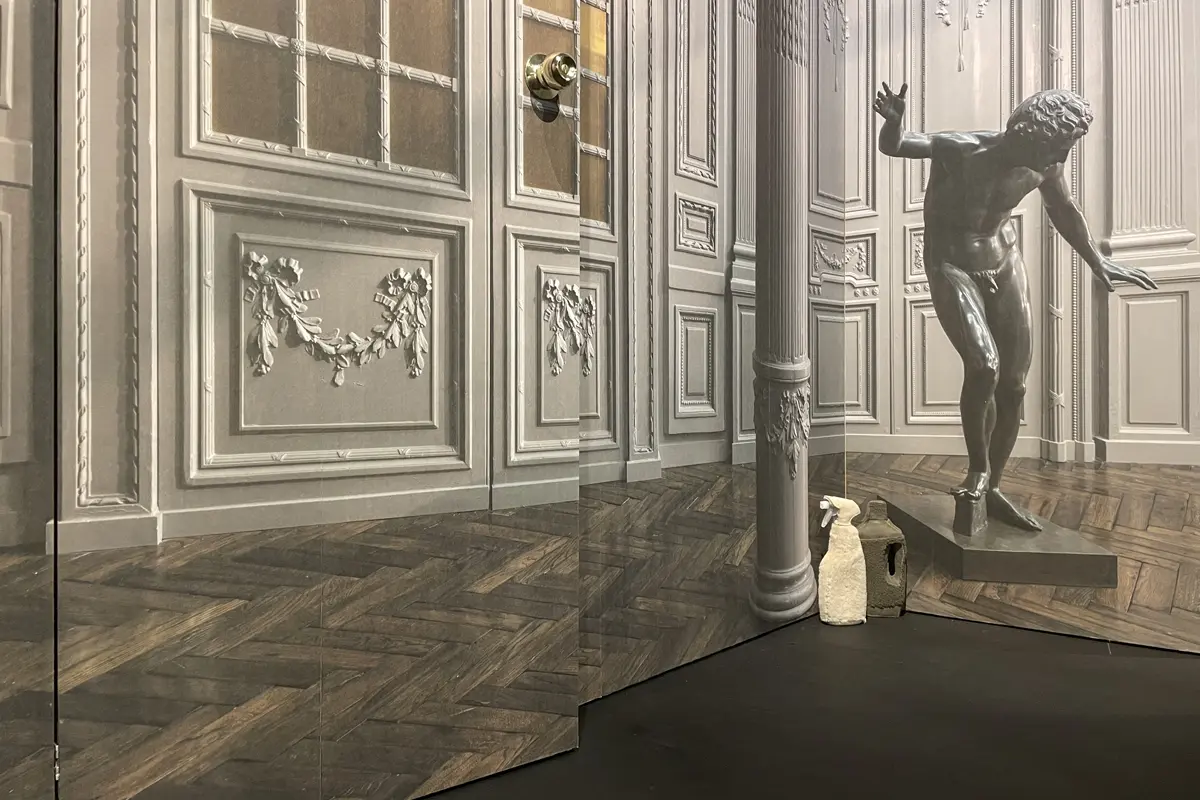

Aquafil then uses discarded plastic to create ECONYL®, a yarn made with recycled nylon, of such good quality that a number of high fashion brands from Prada to Burberry are using it in their new collections. It is changing the high-fashion landscape and birthed the Prada x Aquafil collaboration, which aims to substitute all virgin nylon used by Prada into ECONYL® by the end of 2021.

Healthy Seas: Transforming Discarded Fishing Nets into Clothing and Automobile Interiors

Ghost nets and other forms of discarded fishing gear are a growing problem haunting all oceans across the globe. Abandoned nets pose a hazard to marine life as they wash about polluting beaches, suffocating coral reefs and accumulating on the seafloor. As they float, they continue to capture and kill marine life, such as fish, sea turtles and dolphins. It is often hard to quantify exact statistics of marine pollution due to size and depth of the ocean, however a 2018 study claims that 46% of the Great Pacific Garbage Patch is made of discarded fishing gear. Today, that percentage may be higher still.

In light of this, in 2013 Healthy Seas, an NGO based in Milan concerned with collecting discarded fishing gear and recycling it, was born. Healthy Seas operates in a circular way, undertaking the journey from waste to wear by transforming discarded nylon into clothing, beachwear and even car interiors. Jenny Ioannou, Communication Manager at Healthy Seas explains:

«Unfortunately, ghost nets can be found in all seas and oceans. Fishermen or local divers give us tips on where to operate, and we also conduct surveys to better organise clean-up dives. The work of Healthy Seas focuses very much on preventing marine litter: we work together with fishermen to dispose of their waste nets before they end up in landfills, or even worse at sea and organise events to educate the public».

The Hazards of Abandoned Fishing Nets at Sea and the Complicated Legislative Issues Surrounding their Disposal

Fishing nets are discarded at sea for an array of reasons. Sometimes, they are lost due to irresponsible behaviour by part of fishermen, who may cut them loose to avoid scrutiny of the coast guard if they are operating illegally. Other times, nets can be carried away by storms when they are not set securely: if a net gets stuck while in use, it can be very costly to remove it, so fishermen leave them where they are rather than bringing them back ashore.

Finally, complicated legislative issues may be one of the leading causes for discarded nets being left at sea, as it is easier for fishermen to abandon their nets rather than dispose of them properly. This happens because in the EU, materials collected at sea are considered as ‘hazardous waste’ which means that they must be eliminated following complicated, costly and lengthily procedures. Jenny Ioannou, communication manager at Healthy Seas explains:

«The EU Waste Shipment Regulation (EU WSR) is not helping environmental initiatives and organisations to send their recovered materials for recycling. In our case, waste fishing nets belong to the hazardous waste category. Italy is an exception which hopefully can be used as a showcase to try and push other EU member states to implement the same».

Healthy Seas removed waste from a Greek island in a project five times larger than usual clean-up efforts

However, other countries where Healthy Seas operate have not changed the waste disposal laws, making it expensive and difficult to do the right thing, pushing members of the fishing industry to abandon them rather than bringing them back to land.

This summer, in June 2022, Healthy Seas carried out a project which is five times larger than their usual clean-up on the island of Ithaca, in Greece. Due to the wide presence of fish farms across Greece’s mainland and island coastlines, the country is burdened with a growing number of ‘ghost farms’ where the equipment of entire fish farms is sunk to the bottom of the sea once the enterprise ceases operations. It is estimated that in Greece, up to 20% of marine waste is composed of discarded nets. Jenny Ioannou tells Lampoon:

‘This sort of environmental crime is the reason we went back to the mythical island of Ithaca two years in a row, removing 101 tons of nets and other marine litter from the seafloor and coasts.’

Over the course of 8 days alone, Healthy Seas removed 76 tons of waste from the Ithacan coastline.

Healthy Seas and Aquafil: Fighting Marine Pollution with Circular Economy

But what does Healthy Seas do with all the waste it collects? Complicated problems require complex solutions, and one group of actors cannot solve this problem alone: volunteers, NGOs, private enterprises and government bodies must all work together to promote change. Healthy Seas knows this well and collaborates with a number of partners who work towards this common goal. In particular, Aquafil is one of Healthy Seas most important and long standing associates, as it is the company responsible for turning the discarded nets collected at sea and transforming them into 100% recycled nylon.

Aquafil is an Italian company founded in 1965 near lake Garda. The company has made history with their invention of ECONYL® nylon and Maria Giovanna Sandrini, Chief Communication officer explains:

‘Aquafil is the living testimony that a different approach is possible, and many did not believe we could actually transform waste into a valuable material. Now, it is one of the most desirable ingredients used by admired brands around the world. We are champions in the circular economy revolution and today, other organizations look to us on how to apply the closed loop story to other industries.’

Aquafil and Healthy Seas: Turning Discarded Fishing Nets into Recycled Nylon

Together, Aquafil and Healthy Seas provide an invaluable service: while the latter collects discarded fishing gear at sea, the former breaks it down transforming it into ECONYL® which can be recycled infinitely without losing quality, something which is impossible to do with traditional nylon that is easily contaminated. Fishing nets retrieved by Healthy Seas are cleaned, sorted and sent to Aquafil which oversees their break-down along with other forms of nylon waste, to be regenerated into ECONYL® which is used to make a wide array of objects from sunglasses to car interiors. Jenny Ioannou tells Lampoon:

‘We collect waste nets and ensure they become a valuable resource. Nylon fishing nets are regenerated together with other nylon waste by our partner Aquafil who turn it into ECONYL® yarn to produce new products.’ For example, Prada, one of Healthy Sea’s partners, is using ECONYL® in their new collection and hopes to use more recycled nylon in its products in the future for the fabrication of bags, duffle coats, belts and backpacks.

Production of Nylon and its Environmental Costs

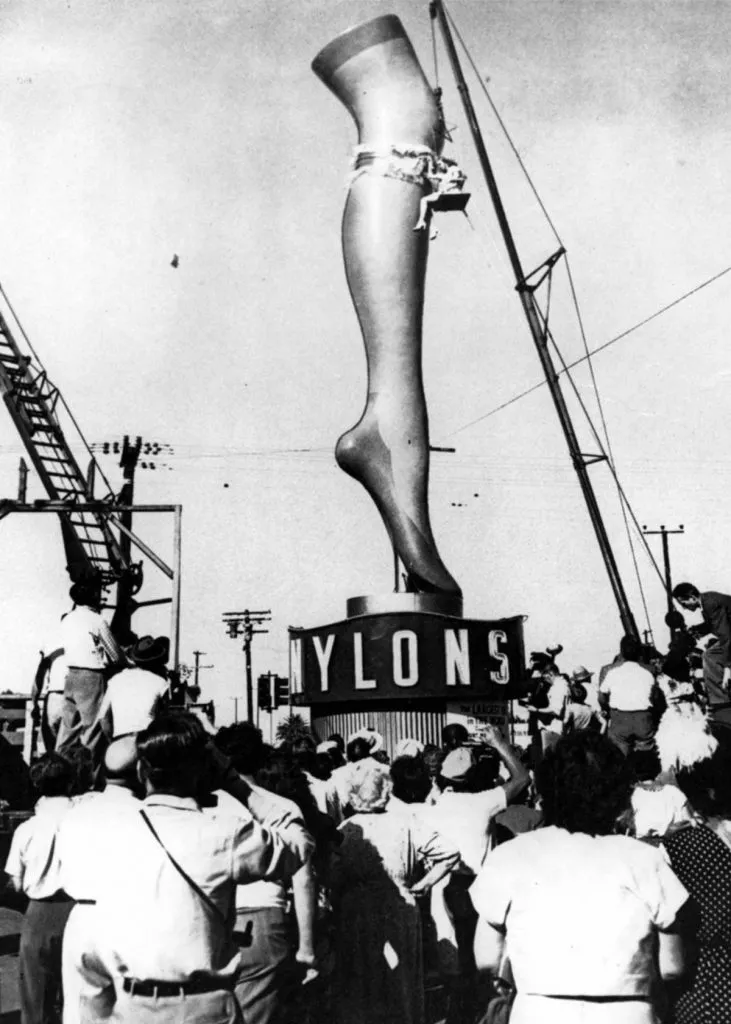

Nylon, or polyamide, is a synthetic polymer: a type of plastic that was invented in 1935 by Wallace Carothers, an American chemist working for the chemical manufacturing company DuPont. Today, nylon is mostly used in the fashion industry to make swimsuits, raincoats, tights and activewear, making up 12% of all synthetic fibres produced worldwide.

The most widely used form of nylon is called nylon 6 which is produced by applying heat to fuse two molecules found in petroleum, releasing water to create a big polymer molecule. This process generates a highly flexible and durable material which does not need ironing and is waterproof, stretchy and elastic. The make-up of the material makes it extremely versatile, however because it is petroleum based, its production and disposal have high environmental costs.

Not only does the production of nylon generate CO2 but it also emits large quantities of nitrous oxide, a greenhouse gas 300 times more potent than CO2, mainly associated with the farming industry, both due to runoff of fertilisers and manure from intensive livestock rearing. Furthermore, nylon production is highly water and energy intensive posing high environmental costs which can be avoided by recycling already existing nylon.

The Circular Solution: ECONYL® Provides Sustainable Alternative to Traditional Nylon

Utilising recycled nylon like ECONYL® diverts waste from landfills and its production uses far fewer resources than ‘virgin’ nylon. Maria Giovanna Sandrini from Aquafil explains:

‘ECONYL® regenerated nylon comes entirely from nylon waste such as old carpets, discarded fishing nets and plastic components. Not only it is produced by regenerating waste, due to its chemical composition, ECONYL® nylon can also be recycled an infinite number of times. This means that no fossil oil usage is needed. Its production has a lower impact on the environment equal to 90% less CO2 emissions if compared to the standard nylon production.’

ECONYL® is a 100% recycled and recyclable fibre made from pre-consumer (fabric scraps) and post-consumer waste (fishing nets, old carpets etc.) and is certified from Oeko-Tex Standard 100 guaranteeing the material does not contain any materials harmful to human health. Due to the fact that in can be regenerated over and over again, ECONYL® is the perfect circular solution as it is able to maintain its high quality and is used by a number of sustainable brands, including Patagonia, Peony and recently Prada, who’s sustainability policy foresees the substitution of all virgin nylon with ECONYL® in future collections.

The Sustainability of ECONYL® Nylon towards Bio-Nylon

On one hand, ECONYL® is largely more sustainable than nylon as it does not share its heavy carbon footprint, has lower water costs and can be recycled infinitely. On the other, because it is made of petroleum, it can take 30 to 40 years to decompose in natural environments and if utilised to make clothing, it will continue to shed microplastics with every wash. In light of this, Aquafil has been experimenting with bio-nylons made from plant origins:

‘We are working on many different projects such as the production of bio-nylon coming from renewable resources, and eco-design. By partnering with different companies, we want to create a new way of producing carpets and garments.’

Displaying the brand’s flexibility and innovation in terms of experimenting with new materials.

Cutting the problem at the source

The issues of ghost nets and marine plastic pollution are pervasive across the globe. Initiatives such as the Healthy Seas x Aquafil collaboration illustrate the effort of individuals and environmentally conscious businesses in tackling these issues as best they can, and the support of global brands such as Prada is invaluable. However, helpful as they are, these solutions cannot resolve the problem at the root: until the production of plastic and its derivatives such as nylon are taxed by governments, their production will continue endlessly.

Plastic pollution is so pervasive globally due to the material’s low cost: by making it more expensive through taxing, businesses would be motivated to use different materials. The fashion industry may begin to rely more upon naturally produced fibres for clothing while the fishing industry may return to using hemp nets as opposed to nylon ones. However, for the moment, initiatives such as this are the next best thing.

ECONYL®

A 100% recycled and recyclable fibre made from pre-consumer and post-consumer waste, and is certified from Oeko-Tex Standard 100 guaranteeing the material does not contain any materials harmful to human health.