How digital craftsmanship is redesigning the textile supply chain

From Amsterdam, BYBORRE has established a new model of digital manufacturing that blends transparency, precision, and responsibility — proving that technology can help fashion produce less, but better

The textile industry’s oversized footprint

The textile and clothing industry remains one of the most polluting on the planet. Its environmental footprint is estimated to exceed that of international aviation and shipping combined. The massive consumption of energy, water, and synthetic chemicals used in dyeing processes leads to persistent textile waste and microfibre pollution in waterways. Over decades, the system has consolidated long, globalized supply chains and energy-intensive production methods that have rarely been questioned or redesigned.

Fossil dependency and global overproduction

With most textile production concentrated in China, Bangladesh and Indonesia—countries that still rely heavily on coal—the sector continues to emit around 1 billion tonnes of CO₂ annually, nearly 6% of global greenhouse gas emissions (UNEP, 2024).

At least 15% of textiles are overproduced to compensate for potential defects or color mismatches along the chain. The result is a paradox: to secure profit, the industry systematically wastes resources.

Rethinking efficiency through digital innovation

The Netherlands has long nurtured a rich textile tradition. Yet, as production globalized, most Dutch manufacturers relocated abroad. Today, companies like BYBORRE, based in Amsterdam, are rebuilding that tradition through technology. Using advanced digital tools, they optimize material use, reduce waste across all production stages, and minimize the environmental impact of logistics. “There’s nothing we use more than textiles—we are born wrapped in them,” says Borre Akkersdijk, co-founder and Chief Creative Officer of BYBORRE.

Beyond the design phase: digitizing the full supply chain

“The industry entered the Industrial Revolution but never the digital one,” Akkersdijk recalls. While many brands have digitalized design, production chains remain opaque and manual. BYBORRE’s goal is to digitize every link of that chain, making it fully transparent and efficient.

When Akkersdijk began in textiles, manufacturers guarded their processes as trade secrets. Only large corporations had access to responsible materials—an imbalance that inspired BYBORRE’s mission of democratizing sustainable production. Partnering with tech entrepreneur Arnoud Haverlag, they merged textile craftsmanship with digital logic.

Designing textiles like digital products

BYBORRE created a “What You See Is What You Get” editor that allows designers to visualize fabrics in real time, integrating machine and yarn data. “If you can use Photoshop, you can design a textile,” Akkersdijk explains.

Their system predicts outcomes with up to 96% accuracy, reducing the need for physical sampling. The same principle applies to coloring: instead of overproducing multiple shades, the software calculates optimal combinations digitally. This shift—from reactive production to design-driven manufacturing—cuts waste and speeds up decision-making.

Less waste, more control

With full insight into design and production, creators can produce only the meters of textile required for each project. This reduces excess material, cost, and environmental impact.

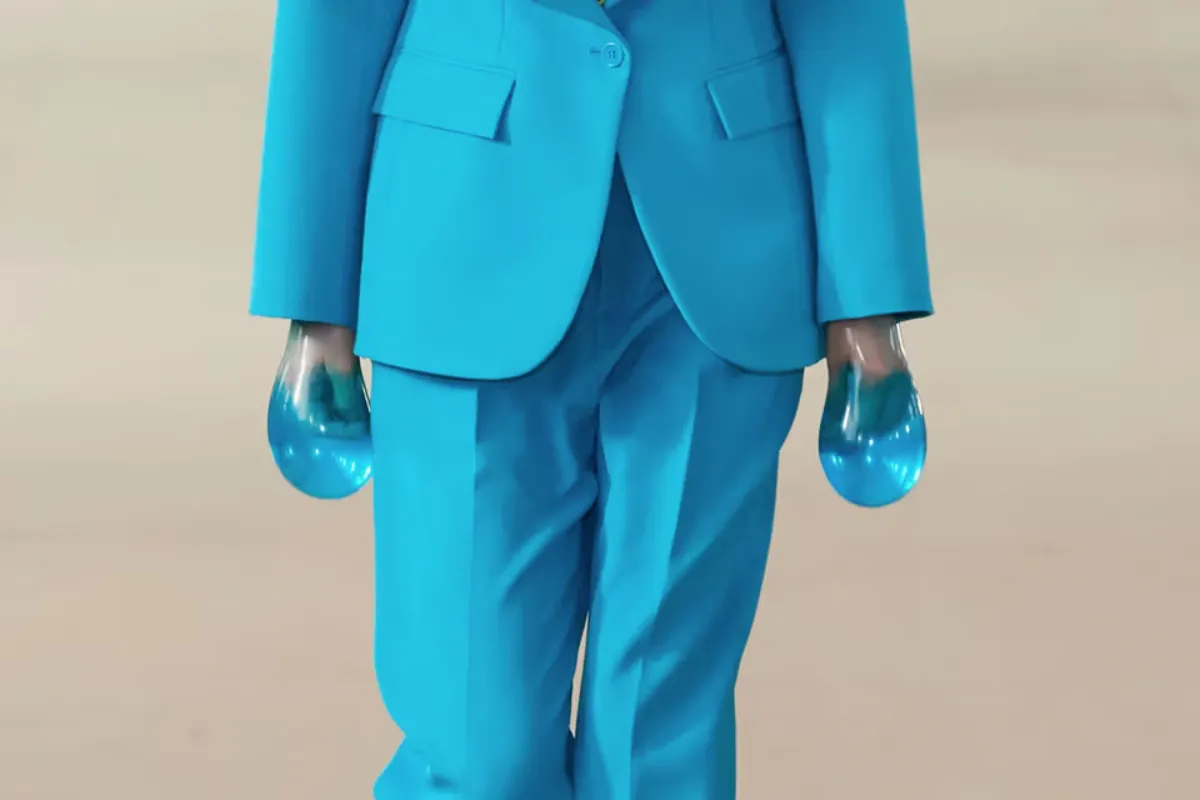

BYBORRE operates an integrated network of 16–20gg circular knitting machines, offering textiles suitable for furniture, apparel, automotive, and fashion. Their materials range from recycled synthetics with zero microplastic release to natural fibers like merino wool and bio-cotton, spanning weights from 150 to 1000 GSM.

Transparency as the new luxury

To address waste and opacity, BYBORRE launched Create™, a ready-to-order textile collection offering 17 base textiles and over 50 colorways, all available within ten days. Each fabric comes with a digital passport detailing every stage—from raw material origin to yarn spinning, dyeing, shipping, and total environmental footprint.

This radical transparency helps designers and brands understand the real cost and impact of their choices.

Open sourcing responsibility

“Resources are not infinite,” says Akkersdijk. “We need to take responsibility from the start.” BYBORRE’s system is open-source, allowing other companies to embed their own identity and values into the process.

Their WoTO™ (Window of Textile Opportunities) platform showcases partners—yarn suppliers, packaging producers, wool companies—celebrating collaboration rather than hiding it. In a world facing resource scarcity, transparency and digital craftsmanship are emerging as the foundation for a responsible, long-term textile industry.