What is a digital clothing label? Fashion’s sustainability code

A new generation of intelligent clothing labels transformed the smallest detail on a garment into a platform for transparency, traceability, and sustainability – linking consumers, brands, and recyclers

How a forgotten fabric tag became a gateway to fashion transparency and circularity

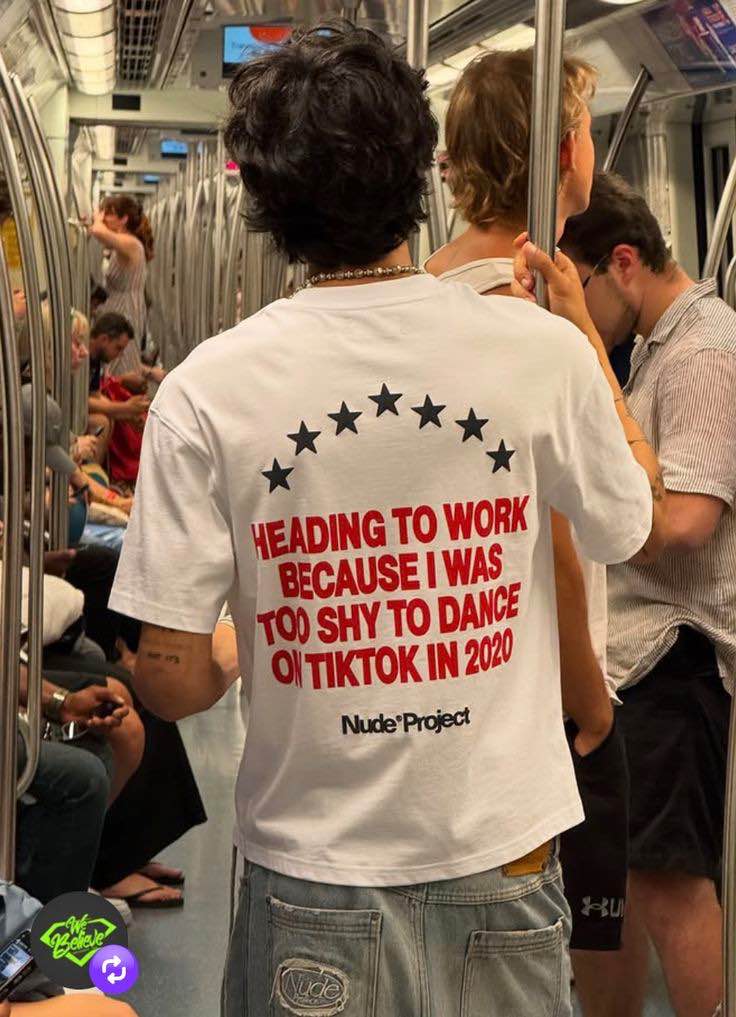

What used to be a small and overlooked piece of fabric sewn inside a garment has turned into a vehicle of meaning, a connector between brands, consumers, and recyclers. The humble label, once limited to washing symbols and fiber percentages, is now the gateway to a garment’s digital life.

Driven by environmental urgency, consumer activism, and regulatory change, labels are becoming interactive data carriers capable of communicating the full story of a product: where it was made, from which fibers, how it should be cared for, and how it can be reused or recycled. The transformation marks a profound cultural shift — from clothing as an object to clothing as an information system, alive and traceable long after it leaves the shop floor.

Why the smallest detail in fashion now drives the biggest sustainability story

Until a few years ago, the label was treated as a mandatory accessory, hardly noticed by the customer and often detached from a brand’s storytelling. Today, it has become a strategic element within sustainability communication. The change is not simply aesthetic: it represents the fashion sector’s attempt to respond to a growing demand for transparency and to the need for accurate end-of-life information.

Companies such as Avery Dennison, a global leader in labeling innovation, and Eon, a pioneer in digital identity platforms for products, are at the center of this evolution. Their work connects the label to the cloud, giving each item a unique digital identity. Through technologies such as QR codes, NFC chips, and blockchain integration, garments can now be scanned, authenticated, and traced across every stage of their lifecycle.

According to Sarah Swenson, Global Senior Sustainability Manager at Avery Dennison, clear and accessible information helps reduce discarded clothing and supports second-hand resale or material recycling. Natasha Franck, founder and CEO of Eon, describes this tracking as the foundation of a regenerative economy, where products retain value through continuous interaction with the ecosystem that produced them.

From digital tags to connected products that speak across the entire supply chain

The distinction between a digitized product and a connected product has become critical. A digitized product simply contains data; a connected product shares that data within a network of stakeholders. This interconnection enables recyclers, resellers, and even regulators to access verified information about a garment’s composition and history, ensuring that no knowledge is lost once the item leaves the factory.

For the fashion industry, this evolution is also a response to the European Union’s Digital Product Passport (DPP) initiative, a core element of the Green Deal legislation that will gradually enter into force from 2027. The DPP will require every product sold in Europe — including textiles and apparel — to carry a digital identity containing environmental impact data, composition details, and instructions for reuse or recycling. What was once voluntary is becoming mandatory, setting a new benchmark for traceability and accountability.

Inside the data revolution: how traceability is becoming the new supply chain language

The path toward full traceability begins at the source. Recording each step of the production process — from raw fiber to finished garment — requires not only technological innovation but also a deep cultural shift within brands. Blockchain solutions offer scientific precision in documenting transactions, while other digital tools, such as scanners and cloud-based apps, allow manual input where digital infrastructure remains limited.

Swenson acknowledges that tracking at the farm level remains challenging, particularly in developing regions with scarce digital access. To address this, Avery Dennison collaborates directly with local manufacturers in Bangladesh, implementing scanning and data-upload systems that feed information into global traceability platforms. Eon, on the other hand, partners with specialized traceability providers that monitor material flows before creating a digital certificate for each product — a kind of passport that ensures data integrity and follows the garment throughout its life.

During production, real-time data such as CO₂ consumption or energy use can be recorded and made visible to brands and, eventually, to end customers. The entire chain becomes a network of verified steps, each contributing to the transparency of the final product.

How connected garments are redefining the relationship between brand and consumer

Once sold, the product does not disappear from the brand’s sight. Through digital labeling, it continues to communicate. For the first time in fashion history, brands can maintain a constant and direct relationship with their customers long after the purchase.

This connection redefines consumer engagement. Franck notes that the customer is now a stakeholder in the circular value chain — someone who can influence how a garment is reused or reintegrated into the system. QR codes and digital apps allow users to unlock a garment’s profile, showing not only its origin but also its next possible destination: resale, repair, donation, or recycling. Some companies reward this participation through vouchers or discounts when customers return used garments.

The rise of circular fashion platforms and post-consumer recyclers such as Ambercycle demonstrates how this ecosystem can function in practice. Old garments are collected, processed, and transformed into new fibers, which are then reintroduced into brand supply chains. Through digital IDs, every stage of this circular loop can be documented and monetized.

Why circular economy principles are shaping the next decade of fashion policy

Circularity is no longer a distant ideal but a legislative requirement. The concept of Extended Producer Responsibility (EPR) — now embedded in several national and regional frameworks — obliges brands to manage the afterlife of their products, proving that items placed on the market can be recovered, reused, or recycled.

Digital labeling technologies are proving essential to meet these obligations. They allow companies to display verifiable data on collection rates, material recovery, and carbon footprint. More importantly, they make circularity measurable and communicable. For consumers, the label has become the first point of reference when deciding how to treat a garment at the end of its life — whether to resell it, repair it, or recycle it.

Swenson points out that by reconnecting brands, consumers, and recyclers through a shared data system, fashion can move from a linear to a circular economy without losing control of material flows. Franck adds that through connected products, materials become traceable assets, each with its own value chain and commercial potential.

The future of connected labels: from regulatory compliance to creative storytelling

The transition toward digital and connected labeling is still evolving. The technology exists, but its widespread adoption requires collaboration across the entire fashion ecosystem — from fiber producers to logistics operators, from software developers to policymakers.

What once seemed a minor technical detail is now the symbol of a systemic transformation. The clothing label is becoming a carrier of truth, a compact space where storytelling, technology, and responsibility meet. By merging data with design, it gives garments a voice — one that can speak across time, use, and ownership, guiding the industry toward a future where every piece of clothing is known, valued, and never truly lost.

Chiara Narciso