What is a 4D textile? Is the manufacturing sustainable?

The evolution of 3D printing is 4D. The case of the 4D-Knit Dress by MIT’s Self-Assembly Lab made using only a robot arm, computerized knitting and heat-activated smart textiles

Fashion towards sustainable manufacturing – The 4D-Knit Dress by MIT’s Self-Assembly Lab. The definition of 4D (four-dimension) textiles

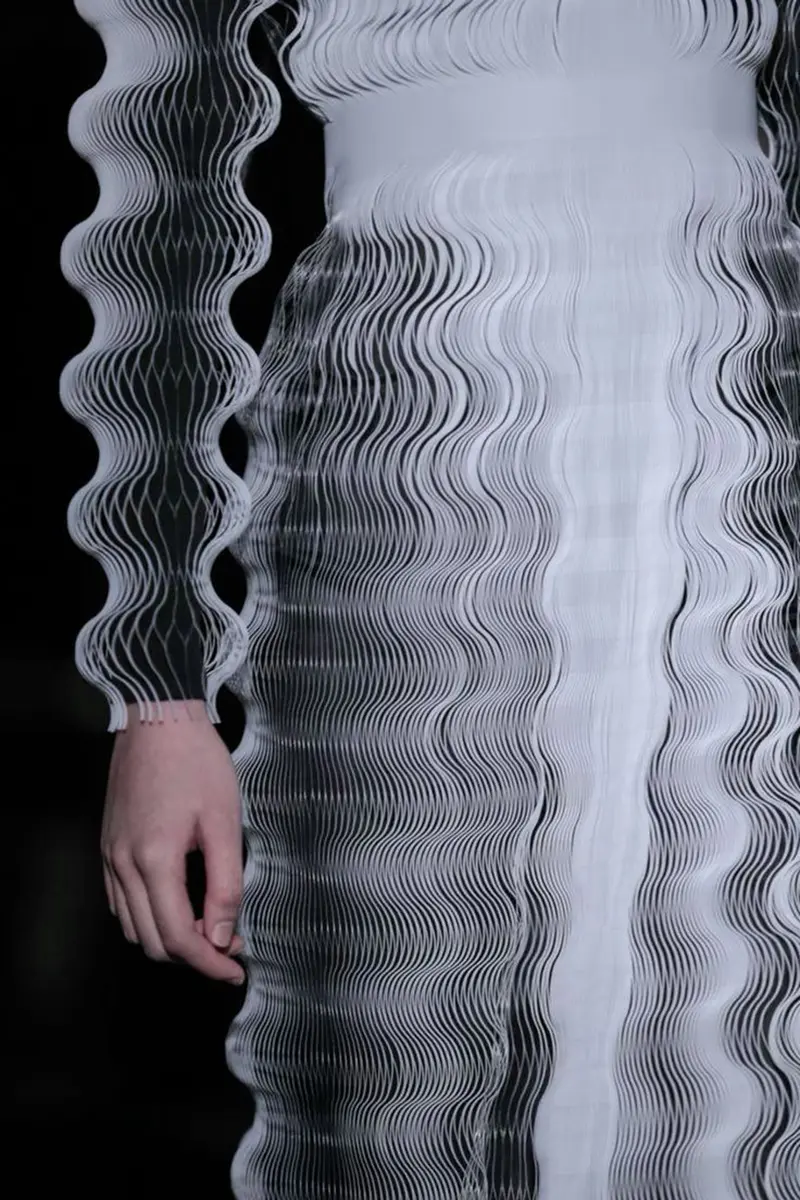

The relentless drive to improve the functionality of textiles, spanning all sectors from medical equipment to fashion, stands as a cornerstone for the sustainable advancement of the textile industry. Smart textiles are a prominent focus of research and exhibit capabilities such as actuation, sensing, colour alteration, and energy harvesting, achieved by adapting their structure in response to external stimuli like temperature, pressure, current, light, and humidity. They find widespread application across many domains and showcase advantages such as high stress tolerance, flexibility, peak output rates, and consistent mechanical properties. MIT’s Self-Assembly Lab, led by Sasha McKinlay, has developed the 4D-Knit Dress, made using a textile manufacturing approach that utilizes a six-axis robot arm commonly found in the automotive industry, computerized knitting, and heat-activated yarns to create personalized dresses of any size.

In response to the supply chain challenges faced by the industry in recent years, the 4D knit technology can adapt to demand fluctuations, changes in size preferences, and seasonal variations hence avoiding one of the biggest problems inherent to fashion: deadstock waste management.

The 4D-Knit Dress by MIT’s Self-Assembly Lab and Ministry of Supply: The sustainable manufacturing process

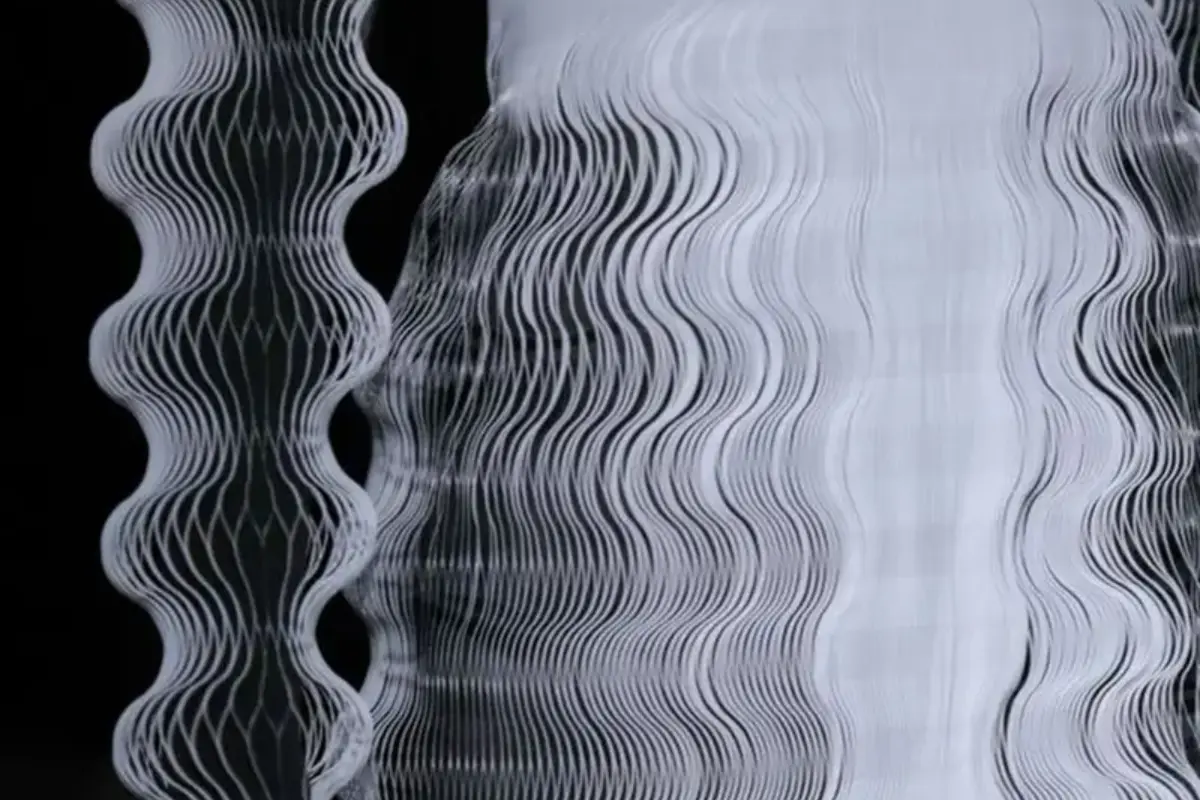

The 4D knitting technology work is about the concept of 4D printing, where the “fourth dimension” of the object manufacturing process is self-assembling over time. In practice, the garment is initially knitted in one piece by a computer-controlled industrial knitting machine, incorporating the active yarn. When the “unprocessed” garment is placed on a mannequin, the robotic arm strategically heats the garment using a heat gun, causing the fabric to shrink to the right extent and in the right places. Depending on how the active yarn is distributed in those areas, it can contract to form its unique features.

The 4D-Knit Dress by MIT’s Self-Assembly Lab and Ministry of Supply moulds to the wearer’s body, thanks to the robot arm sculpting the garment and heat-activated yarns dried by the arm to style the fabric. This adaptable dress can even be modified after use, allowing wearers to change its appearance using the robot arm, ensuring the garment’s longevity and versatility. Once the garment design is programmed, the robot arm produces multiple dresses. Heat-activated yarns, following the robot’s instructions, enable various styles like pintucks, pleats, or cinched waists without traditional sewing methods.

Translating the heat activation process into a programmable robotic procedure was made possible by a graduate student in architectural design: this precision-controlled application ensures fibers bundle up in specific zones upon heat application, effectively tailoring the garment.

The 4D-Knit Dress: the partnership between Self-Assembly Lab and Ministry of Supply

The 4D-Knit Dress is exhibited at the Ministry of Supply’s flagship store in Boston. It was produced in a limited prototype run. The brand’s aim is to leverage aerospace technology, robotic engineering, and thermal analysis in business wear using beta testing with customer input and feedback, integrating early adopters into product development to ensure optimal fit and functionality.

The Ministry of Supply collaborated in the development of fibers, yarns, knitting techniques, and activation processes, and they had utilized the 4D technology during the pandemic to swiftly produce personalized face masks tailored to individual facial contours. The Ministry of Supply is now expanding the manufacturing process for the 4D-Knit Dress in collaboration with industrial knitting partners to distribute it to more stores. They dedicated several years to achieve precise control over the textile’s transformation direction and ensuring specific degrees of transformation at different temperature thresholds. It took some time to strategize how the robot could access all areas of the dress: a commercial heat gun, resembling a handheld hair dryer, proved too bulky for the task, so much that they had to come up with a compact design, a six-axis robot, similar to those used in factory settings for welding or assembly, where they scripted the robot’s actions. Challenges comprehended: the temperature and timing for heat application, and the precision in applying heat to activate fibers on each garment.

According to the Self-Assembly Lab, the dress retains its softness, stretchiness, and resilience after heat activation, with an efficient and scalable production process. It is also machine washable in cold water.

4D smart textiles: The role of 3D printing and the evolution in 4D printing for textile manufacturing

3D printing, an additive manufacturing technique utilizing digital model files and bondable materials like powdered metals or polymers, constructs products layer by layer. In textile manufacturing, algorithms generate patterns of curves that, when manipulated by tensions, give rise to structural formations. In general, the primary types of 3D printing technologies are solid, liquid, and powder additive manufacturing. Despite the versatility of 3D printing in creating objects, there’s a need for assembly, lacking flexibility and environmental adaptability, which 4D printing aims to address. 4D printing is an evolution of 3D printing, and enables dynamic changes in printed structures under external stimulation. It integrates design concepts directly into materials, facilitating automatic assembly and adaptation, and streamlining product design, manufacturing, and assembly processes.

In 4D printing, material structures are fabricated with the capability to dynamically alter their properties in a deliberate manner over time. Beyond the conventional three spatial dimensions, the fourth dimension encompasses the temporal aspect, indicating when a modification in properties may occur subsequent to the initial 3D printing process.

Which textile raw materials can undergo the 4D printing technology?

The raw materials utilized in 4D printing are defined as smart, reacting to external energy by altering their properties or shape. This category includes changes in polymer-specific properties like viscosity. These types of raw materials are classified as active or passive, with variations in their homogeneous or heterogeneous composition during manufacturing: for example active materials encompass a range including piezoelectric, shape-retaining, magneto strictive, electrorheological, and magnetorheological substances and are typically combined with basic or passive materials, which do not change independently over time due to their inherent properties.

In the realm of textiles, the concept of 4D printing expands to encompass a hybrid, time-evolving material structure termed as 4D textiles, comprising generatively produced heterogeneous microlayers and textiles. A 4D textile typically comprises at least one layer of textile embedded with smart materials or adorned with smart structures. 4D textiles represent a fusion of elastic textiles and 3D printing, where the pre-stretched textile employed in printing, along with internal fabric strain, induces curvature in the prototypes.

The core concept behind these 4D textiles involves storing energy in the textile material before printing and subsequently releasing that energy to influence the form and function of the printed prototypes. Classical knitted fabrics made from elastic materials are preferred for their exceptional elastic strain and adequate recovery force. Among shape memory materials –or stimuli-responsive materials –, shape memory polymers have garnered attention due to their cost-effectiveness, lower density, strain recoverability (up to 600%), ease of shape design through simple mathematical modelling, and robust recoverability under external usage conditions.

The supply chain challenges. What changes could sustainable manufacturing bring to the textile industry?

Imagine a fashion industry where every garment is custom-made, eliminating the need for mass production of various sizes and styles that often go unsold. This shift towards made-to-measure fashion reduces fabric waste, conserves resources, and minimizes pollution, leading to a reduced environmental impact. The 4D Knit Dress not only offers customization but also tackles fast fashion’s environmental impact. Unlike traditional cut-and-sew processes, this dress is crafted in one piece, reducing waste. Sasha McKinlay from the Self-Assembly lab envisions a future where retailers can minimize size variations by offering adaptable dresses, fostering sustainable manufacturing practices in the fashion industry.

4D printing holds the potential to contribute to sustainability in various ways, albeit its impact hinges on its application and the specific materials utilized. The real-time nature of 4D printing raw materials equips them with accident prevention capabilities. These materials swiftly detect parameter changes, promptly signalling and proactively addressing potential issues. It facilitates the creation of self-assembling components, minimizing packaging, transportation, and assembly-related waste. This approach aids in reducing the environmental footprint of manufacturing and construction, as waste is entirely avoided, and only the necessary product is packaged, transported, and assembled. 4D printing allows for the production of adaptable objects, diminishing the necessity for multiple fixed components. This leads to resource savings, reduced waste, and more efficient material utilization.

It’s necessary to acknowledge that while 4D printing presents these potential cost-saving benefits, the technology is still in its nascent stages of development, and widespread adoption may necessitate investments in R&D. It prioritizes sustainable design, responsible material selection, and energy-efficient production; with most of the technical hurdles surmounted, the 4D-Knit Dress project may open doors for further exploration and innovation.

Self-Assembly Lab, MIT (Massachusetts Institute of Technology)

Self-Assembly Lab, MIT (Massachusetts Institute of Technology) is a research lab focused on the development of self-assembly and programmable material technologies. They have created the 4D-Knit Dress using heat-activated yarns, computerized knitting and smart textile materials.

The Ministry of Supply

Headquartered in Boston, it is an American fashion brand specializing in business wear. Established in 2012 by former Massachusetts Institute of Technology students, the brand incorporates temperature-regulating materials similar to those used by NASA astronauts in their attire.