Since its foundation, the company has been using spring water for the milling of their paper. Producing from hemp fiber doesn’t require bleaching or chloride

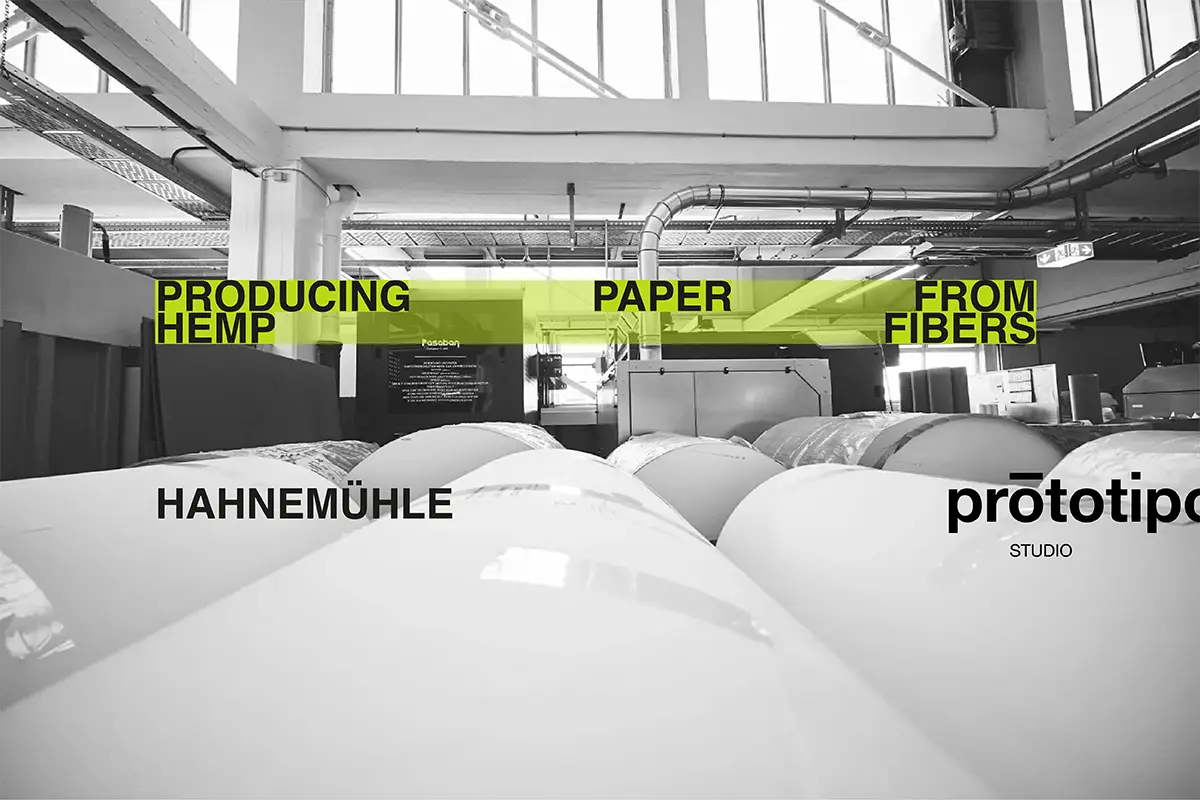

Producing paper from hemp fibers: Hahnemühle

Hahnemühle is a 438 years old paper manufacturer producing paper uninterrupted in the same location, Dassel, Germany. Awarded Brand of the Century amongst the oldest paper mills in the world. The reason why the papermill is in a town in southern Lower Saxony, is for the pure spring water they use from their own wells; which is the recurrent element of paper production since their inauguration. We spoke to Hahnemühle’s team.

«Our spring water comes directly from the wells, which means it doesn’t come out from the surface of the soil. So it maintains the same Ph value, same temperature and pureness all year round. We don’t use any chemical treatment or additives before and after production. It’s safe to return the water to the rivers after the paper manufacturing process. We are controlled very strictly by our authorities because we are located in a natural reserve area». Bettina Scheerbarth, responsible for the sustainability communication program, explained.

The more sustainable choice for papermaking – Hemp vs. wood pulp

Hemp was the main choice for papermaking until manufacturers came across wood pulp, a cheaper paper production option. It has numerous properties that favor its use as a papermaking raw material. As a plant, hemp is more suitable due to its higher cellulose and lower lignin content. About one-third of the fiber of the hemp stalk that originates from the outer layers or bark is moderately long. A desirable quality for developing the high-strength paper. When using handmade manufacturing procedures, paper making is completely natural and organic as there are no toxins or acids involved. As for the resources implied, hemp paper uses less water and the process is faster so it consumes less energy.

Hemp grows much more quickly than trees, taking only about four months to mature from the plantation. It is highly resistant crop requires negligible to no pesticides. While more than 40% of trees are planted for the sole purpose of consumption or paper production. Hemp can instead prevent deforestation, with one acre of hemp producing as much paper as four to ten acres of trees over twenty years of the cycle. Hemp has a higher portion of cellulose and a higher concentration of the principal ingredient required for paper making.

Trees are made up of only 30% cellulose, requiring the use of toxic chemicals to remove the other 70%. Hemp, on the other hand, can have up to 85% cellulose content. As for the lignin content, hemp has a lower percentage, around 5-24%, whereas wood has 20-35%. This is advantageous as lignin must be removed from the pulp before it can be processed as paper. Hemp paper is more durable and does not turn yellow, cracked, or deteriorate like tree paper, which is more affected by aging.

Hahnemühle experience with plant fibers like bamboo and agave

Hahnemühle papermill was founded in 1584 when paper was made from old textile and cloth and hemp as well. This idea to come up with the production of hemp paper is part of a more sustainable circuit carried on by Hahnemühle.A producer who has previous experience with plant fibers like bamboo and agave. «Until the Seventies, manufacturers created paper by hand. It was scoped from a well where the water and the fibers were mixed together into the so-called pulp and scoped sheet by sheet with the mould from the pulp. This kind of paper is the most valuable paper around.Similar to papermaking by hand, there’s the technique of using a mould making machine. We are one of the rarest companies in the world who still have them running».

«This technique involves a cylindrical mould making machine, where the mould rotates slowly and evenly and the paper is produced at the highest point of the mould; the fibers kettle in disorderly fashion combining to a wet paper fleece. During the production process the water firstly flows through the mould. The paper is taking over by felts who absorb the water and gets the paper the typical genuine artistry structure».

«Sheets with genuine deckled edges or paper on rolls can be made and watermarks can be applied at the cylindrical mould. At the Foudrinier paper mashine the paper fibres mixed with spring water lands in a long wire that aligns the fibers in the same direction. When the water goes through the wire, it returns back into the circuit of our production system. Then the paper is dried and gets the structure from felts which are running through our paper machine that transports the paper fleece. This is how our hemp paper is produced» continued Scheerbarth.

The structure and performance of Hahnemühle’s hemp paper

Hahnemühle’s hemp paper is made from 60% hemp and 40% cotton. «Every type of paper is unique in its own way due to the production design. When you analyze the hemp paper, for example, you can see it in the surface. It has a haptic touch and feel and it reacts differently when it’s printed on. It has the same high quality but because it’s a different material. The surface of the final product looks and feels different due to the pure color of the fiber. We needed this combination of hemp and cotton because hemp fibers are very stiff.

This way we’re able to make them run smooth in the printers. In terms of performance hemp paper is just the same as traditional paper. The cotton we use is not grown for us for papermaking but it’s a byproduct from the textile and oil industry. The cotton fibers we use are usually discarded. They are very small and fine and can be found clinging to the cotton seeds. We are super picky when it comes to our cotton sourcing. We look at suppliers that are certified, we look into the fact that it’s grown sustainably and child labour isn’t involved» told Eveline Eisermann, Marketing communication specialist. Also, hemp paper is 100% biodegradable. The hemp is sustainably grown and sourced from Europe. A big advantage when it comes to transport because it doesn’t have to go through long distances.

Hahnemühle: three categories of hemp paper

«We have our products divided into three categories: Hahnemuhle hybrid hemp paper for the book printing; hemp paper for the artist paper and hemp paper for the fine art printing» Heidemarie Hinger, Product manager at Hahnemühle told Lampoon.

«It is already a big portfolio compared to other manufacturers and our newest innovation is the sugar cane paper from the waste plant of sugar production that is called bagasse. There are only a few paper manufacturers that produce from plant fibers, especially hemp. We try to know about the fibers, collect knowledge about it and then apply this knowledge to other sustainable raw materials. One of the project that we made was with artist, photographer and digital storyteller Maren Krings. She photographed the reinvention of hemp on the whole planet and wanted to come up with a book also printed on hemp paper. And that’s why we, together with her, developed the paper for book printing for the publishing business. That’s a push that came from the market».

The use of renewable sources for hemp paper production

Scheerbarth stated that energy they use for production comes from renewable sources only. The gas used for drying paper is different from the one consumed for the making of paper from wood pulp. «We have had measurements made: our consumption is 40% less due to installments we made that makes us frontrunners in the paper manufacturing industry for artistry paper which is a special paper branch. We produce less paper per year than a newspaper production company because our machines are running very slowly to get the high quality we want to have». Hemp paper for book printing is much more expensive than standard paper so it is not suitable for the mass market. Hahnemühle has targeted this type of paper for special projects and artist paper is conceived for a niche market.

«There is a lot of potential for the hemp paper but I wouldn’t say for the mass market. Producing it it’s easier and faster but it’s definitely much more expensive when it comes to handling the fibers, because it is four times more time consuming to have them ready for paper. We have to do a lot of milling so they can build and evenly make fine paper for book printing for the high quality result we want to obtain. This to make sure we have the right sheet formation and this needs some optimization on the machine parameters for example. Because the fibers might stick together very easily. The manufacturing is done with small machines; the optimization by hand. We cannot address it for the mass market at the moment because of the individuality of the product».

Will wood pulp ever be replaced? Disadvantages of hemp paper and future expectation

It makes sense to review the use of trees for paper. The cons of papermaking from wood pulp are serious: the energy consumption of paper mills is enormous. Also, in terms of recycling, even the best paper from trees can go through a maximum of three recycling processes, whereas hemp paper can go through seven or eight. Making paper from hemp paper does not require any bleaching or use of chloridepaper; from wood pulp is given a white color by the use of these substances, harmful to the environment.

On the other hand, the primary con of hemp paper is the cost of hemp cultivation. This has a high initial investment needed when farming it. In terms of quality and strength of the fibers, hemp provides durable, highly performant and quality paper. In contrast to pulp paper that isn’t as tough and durable. At present day, it is significantly cheaper to create paper from wood pulp, mainly because it is an established industry, against hemp industry, that is relatively new, and hasn’t yet had the chance to develop a foothold. Whether or not companies will figure out how to mass-produce hemp paper inexpensively remains unclear. It is certain though that hemp paper is a better product to come out with. It’s biodegradable and it is not so impactive on the planet.

Hahnemühle FineArt, Inc.

A paper manufacturing company located in the Relliehausen district of Dassel, Germany. They produce coated paper for inkjet printing; artist’s paper for traditional painting and printing techniques; and filter paper for industry and research, using fibers from plants, such as agave, bamboo and hemp.