Human Material Loop is a project researching ways to integrate human hair as a sustainable material for the industry into a zero-waste recycling system

Introducing human hair into the production chain: Zsofia Kollar presents Human Material Loop

The population growth rate and the standard of living are increasingly raising. We need to value waste as a commodity that we can no longer afford. Human Material Loop is positioning human material in the textile industry. Their aim is to put value back into the waste that we physically produce. More specifically, in hair.

Zsofia Kollar, founder and designer, explained the characteristics and potentialities of human hair. «We are a company that is processing waste human hair from hair salons to develop high performance textiles. The long term goal is to create a global system so there will be no hair waste streams. It is also make a greater impact by integrating it into the textile industry, lowering the current use of cotton or wool. We are going to reach that goal by forming partnership and collaborations with other companies. We want to make it into a commonly used material in the production system».

Over 72 million kilograms, about 159 million pounds, of human waste ends up in landfills every year just in Europe. Human hair is a fascinating element representative of every culture. It is so precious on our head, but it becomes neglected once it’s cut. Is it possible to change that paradigm? Kollar did a lot of research on the matter. «Human hair is a keratin protein fiber, just as wool or alpaca. It has a bit higher diameter, but in principles is very much the same. It has extremely high performing capabilities. It has the same strength as steel. The combined hair of a head could support twelve tonnes, the equivalent of two elephants. It can withstand up to seventy percent deformation before breaking, so the elastic recovery it’s extremely high. It is very lightweight with very low carbon footprint. Nobody is allergic to hair, which is also an important aspect when developing a new material for the market. Back in the day, they used hair for thermal insulation in submarines and houses, and as an absorption material. One single kilogram of hair can absorb up to seven liters of oil».

The first piece developed by Human Material Loop was a tapestry piece. Its predominant feature was the oil absorbing capability, created for infusing essential oils.

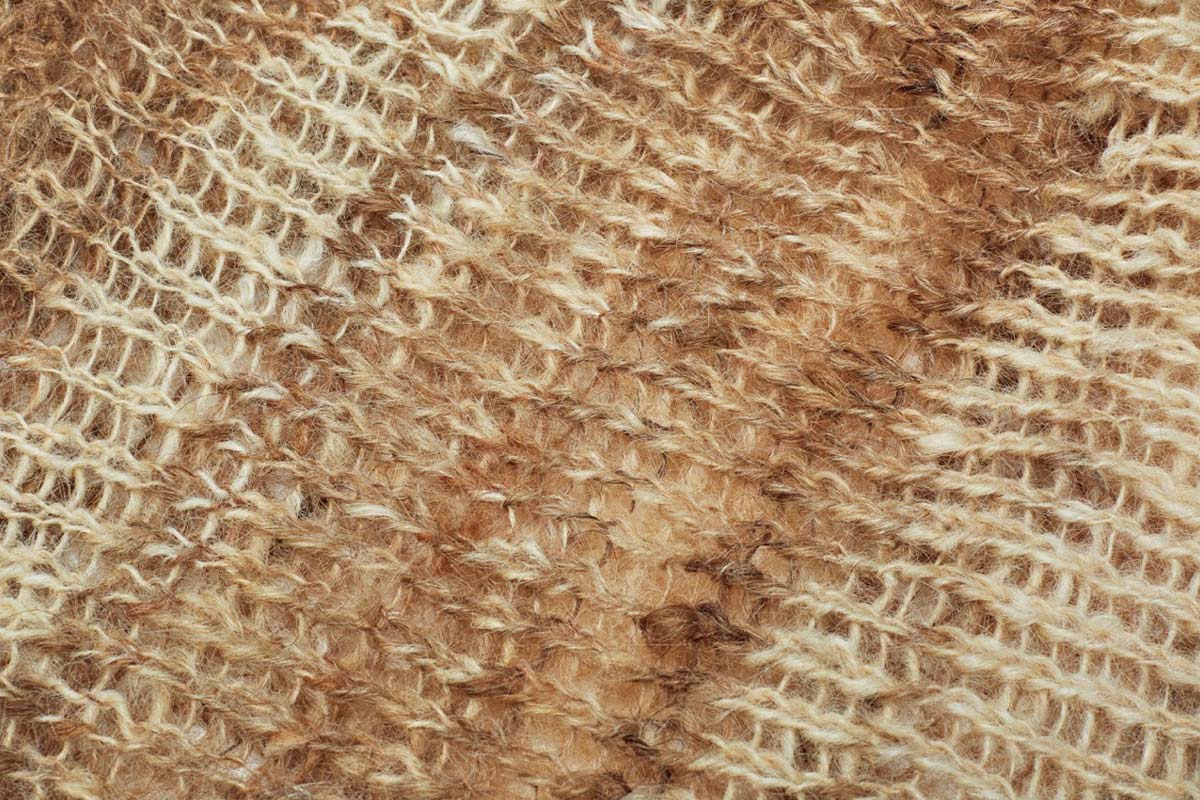

‘Dutch blond’: the prototype jumper made entirely from human hair

Kollar created a sweater made of 100% recycled Dutch blond hair from Amsterdam. While the yarn is currently produced at a spinning mill in Italy, Kollar hopes to have all materials produced locally. «We developed the jumper with the intention so that the hair could be conceived as any other fiber in the market. We are looking for the shift in peoples’ minds. The production of ‘Dutch Blond’ started by investigating the hair salons. Asking where the hair waste was going, and if I could collect the hair to develop it into a product in the garment industry. In the very beginning, we did a pilot with fifteen hair salons located in Amsterdam. This was to see how they are operating and to see how hard it would be for them to separate the hair from other waste material. We collaborated with a logistic partner. They connect more than a thousand salons in the Netherlands now, taking all the aluminium, plastic, and paper waste that go to other manufacturers, while the hair comes to us».

Manufactures must treat animal hair with harsh chemicals to remove blood and other particulates before it can be handled. Once steamed, Kollar says human hair is pretty much ready to go. «All type of hair can work so we don’t select or sort any hair from the salon waste. We just collect everything together, even dyed or oxygenated hair. Many people have this perception that dyed hair is damaged. Actually, there’s no major transformation in the structure of the hair. During the manufacture, the very short ones can’t make it into the yarn. But, we developed another use so we don’t have any waste in the entire production system. About eighty-five percent of collected waste is spun into yarn».

The whole process of the hair fiber is very similar to any other used in the textile industry. «The knitting has made it possible that we don’t need to assemble different parts cut from woven fabric. It’s 100% hair, no glue, no addition, no chemicals. After we had the yarn, we gave it to a fashion designer who knitted the sweater».

Kollar and Human Material Loop future projects will include partnerships with brands working in other sectors. This includes the home furniture and interiors.

A biodegradable nitrogen-packed fiber which could benefit plants

Since it is a keratin protein fiber, it has the same biodegradability as wool. It could take up to two years to biodegrade. This depends on factors such as soil moisture and its overall conditions, or effects of the climate. Hair is seventy percent nitrogen, an essential element for plants. It ensures the available energy to optimize yield. This nutrient is present in the roots as proteins, while enzymes help in regulating water and nutrient uptake. Human Material Loop has gone deep into the research on how they can use hair as a bio-fertilizer.

In addition, the energy usage for processing hair is very low. If wool has to go through twenty-five washings before it can be spun into yarn, Kollar reduced it to one. This is mainly because the raw material they are getting is almost ready and available for production. This is because individuals take care of it until it is cut off. Unlike other materials, it doesn’t require any cultivation. It employs no land or workers and very little water is involved.

Human hair advantages

As explained in the Human Material Loop report, human hair has a lot of qualities. From a technical point of view, hair is abundant, it is non-toxic, and non-irritating to the skin. Consequentially, it is an anti-allergic material to work with. Since it is lightweight, it can be easily transported, even by carbon neutral transportation, like bicycles within cities. Its thermal insulation and absorbing capability can be applied within the construction and heavy duty work areas. It can scent indoor spaces or clean up oil spill disasters.

Also, there isn’t the possibility of identifying a person through the hair that has been dispersed and then collected. Only the hair follicle at the base of human hair contains cellular material rich in DNA. They have to pull the hair out if they want to use it in DNA analysis. A barber or hairdresser cuts off the hair beforehand for Human Material Loop. They don’t contain nuclear DNA and no person can be identified from it.

Human Material Loop

A company exploring the possibilities of waste human hair to create sustainable products, promoting a zero-impact economic system. Founded in 2021 by designer Zsofia Kollar. ‘Dutch Blond’ is their first biodegradable jumper knitted using only human hair fiber