Developments in the dehumidification sector to allow government buildings reaching their zero-emission goals. An interview with Scot Duncan, inventor of HEDS

What is relative humidity control and why we need it

Relative humidity (RH) is a measure of how much water is in the air compared to the maximum amount of water the air can carry. The higher the temperature, the more water the air is able to carry. There are points at which too much water in the air, and even too little moisture in the air, become a cause for concern. This includes growth and spread of mold, fungus, corrosion, and creating a better environment for viral matter, such as Covid, to thrive. A regulated RH should be below sixty percent and above forty percent.

The traditional dehumidification approach in large HVAC systems – Heating, Ventilation, and Air Conditioning – has often been accomplished by condensing water vapor from the airstream as it passes over a cooling coil. Condensation is achieved when enough water from the air reaches the leaving air temperature, typically lower than the temperature required for cooling the space.

To avoid subcooling the conditioned space below setpoint, it is necessary to reheat the subcooled airstream using a separate heating coil. It is implied that a hot water coil or an electric heating coil is required, adding up to the amount of energy used in the process. This cool, dry leaving air is then suitable for cooling and dehumidifying the conditioned space.

How to test humidity control efficiency

Symptoms of a wrong relative humidity level are cracked lips, sore eyes, dry skin and reduced immune defense against bugs, bacteria and viruses.

To test humidity control efficiency, the source of energy used by the equipment needs to be considered, the calculation of the whole system cost and to what extent electricity can be considered a greener choice than gas if the amount of energy implied exceeds certain standards.

HEDS (High Efficiency Dehumidification System)

Scot Duncan is the inventor of the High Efficiency Dehumidification System (HEDS). It is a simple, low maintenance, energy and carbon-efficient way to control relative humidity. HEDS uses energy recovered from the cooling and dehumidification process to control temperature and relative humidity. It cuts energy out of both the cooling and heating process.

«This system uses energy recovered from the cooling process to reheat. To do relative humidity control you subcool the air down, to condense moisture out of it. When you open the dishwasher your glasses get all fogged up — that is condensation. That’s what our conditioning system is doing on a larger scale. Once you get that moisture out of the air, you have to heat the air back up so you can get the glasses back again».

Firms are looking to decarbonize their buildings to meet their corporate ESG goals, but the HVAC process, which is a heavy carbon user, has been considered too hard to reach. Considering commercial office buildings, Duncan explained that the first goal is to keep people safe and to keep the building full of people. If people are going to a healthy facility that’s maintained and it’s comfortable, productivity will increase.

A HEDS-based project can eliminate the need for carbon-based fuels for the heating and reheating systems for temperature and relative humidity control.

«The goal was to make it a long term solution. This equipment can last thirty or forty years. The existing technologies are good, but they require constant maintenance. To make matters worse, the labor pool of high-end maintenance tradespersons are shrinking».

Changes in the government sector

Government buildings use a variety of HVAC systems based on their sizes and geographic locations. Many of them were designed and built decades ago and they are not able to meet the cooling and dehumidification loads that the buildings experience.

The energy recovery systems that are installed in newer buildings can be complex and require maintenance beyond what the staffing and budgets can accommodate.

The U.S. General Services Administration (GSA), with technical assistance from the U.S. Department of Energy’s Building Technologies Office (BTO), in response to the most recent request for information seeking technologies for net-zero carbon buildings, has chosen to install HEDS for evaluations of their avantgarde technology and validate the technical and operational characteristics and their potential for future deployment.

Implementing HEDS requires an engineer, architect, owner, facility management or sustainability person to identify a goal. «We work with the team to determine if HEDS would be a good solution to the problem. We do an energy and cost analysis and search for available incentives, such as funding available to reduce electrical and natural gas energy consumption and GHG reduction incentives. If the team decides that there is a fit, we work with the owners team to solidify the design, final-size the equipment and work out the details for the bid or build package. Then the project gets built, tested and tuned».

HEDS equipment is built out of aluminum; «using less electricity and cutting the whole use of fossil fuels is a goal of ours» precises Duncan.

The cost reduction

Climate is getting warmer and unpredictable, so engineers must be aware to build systems that can advance forward in time. Designs made for today won’t work in ten year time.

A lot of jurisdictions are not allowing natural gas heating in buildings: the cheapest solution first cost – not lifecycle cost – of doing relative humidity control is to use a lot of electricity and after that to use a lot of gas to heat the air back up. Luckily, this system is going away.

HEDS does cost more than a normal system since costs are needed to provide for the energy recovery design and the energy optimization software included with HEDS, that saves energy for all aspects of the HVAC process (the chillers, heating systems, heat pumps, pumps and fans).

People are starting to recognize that simple to operate and easy to maintain carbon-free buildings are necessary to meet the climate change goals in a sustainable manner. Complex HVAC systems can be difficult and expensive to maintain.

The results

Hundreds of millions of dollars are wasted every year to control relative humidity, corrosion, and biological growth problems in facilities and even more are spent on remediation and reconstruction work in office buildings where traditional HVAC systems are unsuccessful and outdated.

At the request of the US Army Corps of Engineers, Duncan developed a solution to combat these problems, helping governments and corporations meet their ESG (Environmental, Social and Governance) goals for decarbonization, electrification and reduced energy use, showing savings over fifty-seven percent for the dehumidification process.

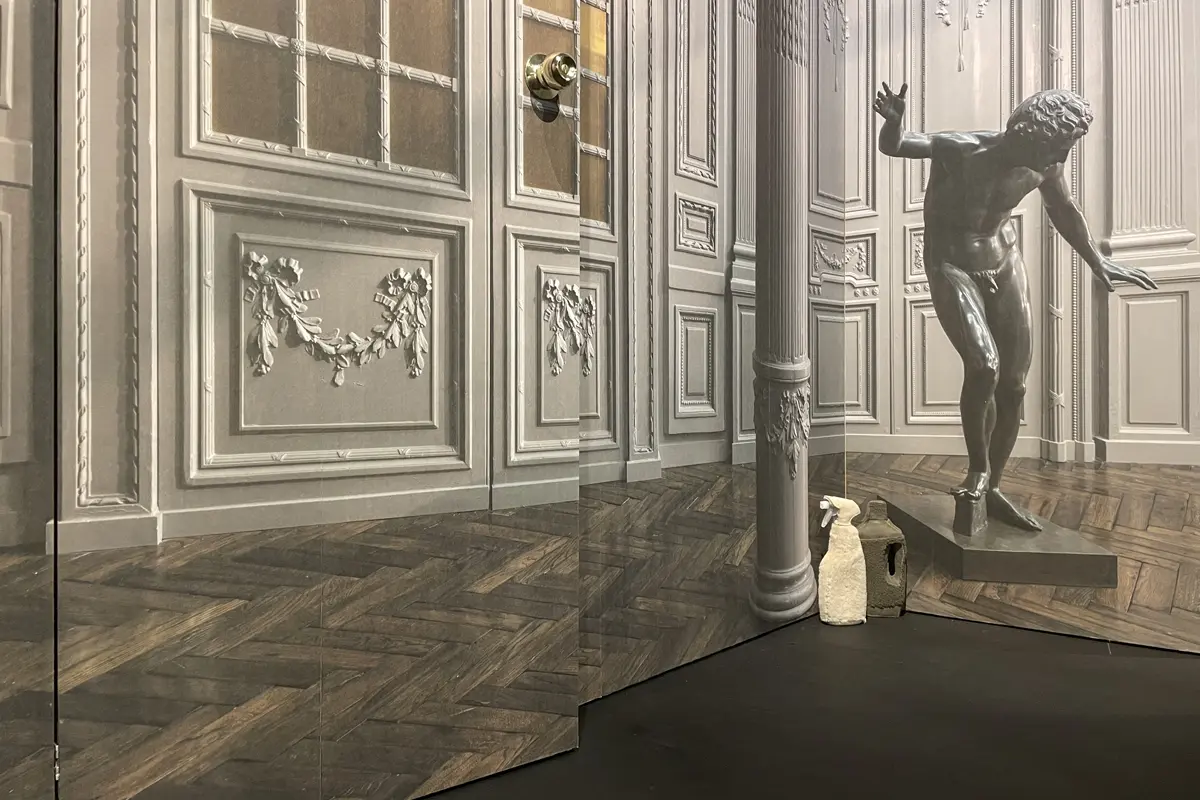

Duncan’s recent projects include a Federal laboratory in San Juan, Puerto Rico and a Fine Arts museum in Southern California — two different climates and different HVAC designs, which are both showing HVAC energy savings over sixty percent. It has been tested that greenhouse gas emission reductions are already showing on these projects. If they convert to heat pumps for their winter heating needs, the decarbonization of the HVAC process will be one hundred percent.

Scot Duncan

President and founder of Conservant Systems. Scot Duncan is an expert in relative humidity control, thermal energy storage and energy efficiency subject matter. Duncan is the inventor of HEDS (High Efficiency Dehumidification System), an energy saving system that uses energy recovered from the cooling and dehumidification process to control temperature and relative humidity.