Armani’s story is an explanation of work ethic

Giorgio Armani, the fashion paradox and the fight against consumerism: we don’t need to produce in a continuous flow, we have to teach our customers to buy less

This article is a reworking of an interview conducted in 2021 by Lampoon’s Editor in Chief: a conversation on sustainability, circular economy, and biodiversity that reflects Giorgio Armani’s commitment. We are republishing it today on the occasion of his passing.

Fashion Unified for Roles and Iconographies: The Battle Against Consumerism and the Paradox

Carlo Mazzoni: Is the fashion industry cohesive or competitive?

Giorgio Armani: Unfortunately, fashion is competitive—and it shouldn’t be. Fashion needs to abandon individualism. It must be cohesive and cooperative in finding shared solutions. Today, more than ever, I believe in designing objects made to last—not creations whose value diminishes in a few months. We need to make more thoughtful purchases, choosing what’s truly worthwhile. Fashion will regain its significance by dressing people in clothes that make life easier and help redefine roles and iconographies.

CM: Fashion is criticized as a driver of consumerism. How can it reinvent itself?

GA: Less entertainment and better products. Consumers must start consuming more responsibly. The fight against consumerism is a paradox: we must teach our customers to buy less. Consumers never demanded mass fashion to release new products continuously. Producers created this situation. Now we must initiate a process of re-education so that consumers understand that if we want things to be done more responsibly, they too must consume more consciously: buying less and better; purchasing products made with processes that minimize environmental impact.

Reducing Emissions, Renewable Energy, Via Bergognone Headquarters, and Green Areas

CM: The Armani Group has set a target to reduce CO2 emissions by 30% by 2030.

GA: Reducing emissions is a process: it must consider the entire production process from raw materials to the end of the product’s life. One answer is to produce less and better, as I mentioned earlier. We need to select raw materials with a low environmental impact, seek new processes, reduce waste and scrap, and use renewable energy sources. We must collect data. To map a path, the starting point must be clear so that progress can be monitored and not just desired or reasonably expected. For its headquarters in Via Bergognone, Milan, the group has had photovoltaic systems since 2014. For all offices and stores in Italy, energy comes from various sources: solar, wind, and geothermal. I repeat: it is a slow and complex process that requires commitment. Heating and cooling systems of production hubs, offices, and stores are centrally controlled.

For the lighting, now largely LED and low-consumption, sensors have been adopted to automatically turn them off when the space is not in use. Via Bergognone buildings were designed to limit consumption and envision sustainable mobility. They were connected to the office on Via Borgonuovo by an electric shuttle. Also, in this regard, charging points for non-polluting vehicles have been installed in the company’s parking lots at the Via Bergognone headquarters. In 2015, coinciding with the opening of the Armani/Silos exhibition space, the urban area around Via Bergognone was redeveloped. This included the refurbishment of sidewalks, replacement paving, and the restoration of green areas that had deteriorated in the past. These areas were used as parking lots. One thing I am certain of is that sustainability should be adopted comprehensively. This is not only in the design of clothing products but also in the production of furniture and accessories, and in the design of offices and stores.

CM: Current changes concern Italian offices and stores. When are changes planned for international spaces?

GA: The changes, which are relatively simple for spaces directly managed by us, require agreement with various partners, wholesalers, and franchisees.

Circular Economy: Starting with Design, a Practice That Stimulates Creativity, Zero Waste

CM: Industrial production: is there a tangible potential to achieve full circularity in the near future?

GA: We need to start with design. Design must compose materials so that they touch but do not mix. It starts with the selection of materials and the design of how those materials can then be separated. We must also include packaging, labels, displays, and wrapping. In 2012, we started eliminating plastic components, and where this was not possible, we focused on compostable or recycled plastic. Emporio Armani’s hangers are made of recycled materials, and our garment covers are made of recycled polyester. Armani/Fiori ribbons are compostable, and the papers from Armani/Dolci are recycled. As you can see, it is a coherent effort. Our RSLs, the lists of substances whose use is strictly regulated, are part of all group supply contracts. They are updated as more advanced technical solutions become available. The circular economy stimulates creativity. It must not remain a declaration of principles reserved for a few capsule collections useful for communication. Fashion change comes from action, not just from declarations.

CM: How does the Armani Group intend to ensure the Zero Discharge policy? What tests are conducted?

GA: Audits regularly conducted at our suppliers lead to a classification of results into five different categories. When the result is unsatisfactory, the supplier is guided through an improvement program that allows them to remain a qualified supplier of the Group in line with Zero Discharge. Follow-up audits, planned within a defined timeframe, detect the required improvements. Non-compliance with standards leads to definitive measures and, in the extreme case, to the termination of the relationship with the supplier

Italian Hemp, Final Prices, Trees in Milan, and the Ring Road

CM: Today, the Italian textile industry does not use Italian raw materials. Emporio Armani was one of the first brands to start using hemp in its collections in 1995, and in 2002, there was a project for growing hemp in Italy supported by Mr. Armani.

GA: Italian hemp is in the experimental phase. There is growing attention to animal welfare because there is a greater awareness of the value of biodiversity that must be protected. An Italian hemp supply chain could meet these needs.

CM: Will radical changes include a variation in final prices?

GA: Yes. Sustainability requires investments and therefore a certain rebalancing of costs and final prices. Attention to the environment is not just a matter of responsibility: it is also a business lever. The growing education and sensitivity of the public make this public more aware and demanding.

CM: Every year, 150 million trees are cut down to turn them into fabric. The Group is collaborating with the Municipality of Milan and ForestaMi.

GA: We have confirmed funding of around 300,000 euros for the regeneration of the entire ring road—the route of lines 90 and 92. The entire urban ring will see renewed trees, shrubs, and hedges. It is a financial investment and an ethical value: those who have the opportunity should intervene.

A National Matter: Armani Silos, Teatro Laboratorio—a Creative Platform and the Foundation

CM: Tourism in Milan is a national issue as the city is the economic capital of the country. The urban environment and green decor in Milan should be the pride and duty of the entire Italian luxury industry.

GA: Giving back to the city part of what it has given me is a commitment that I hope can also serve as an example for others working in this sector.

CM: Could a brand like Armani become a platform to launch other creative talents?

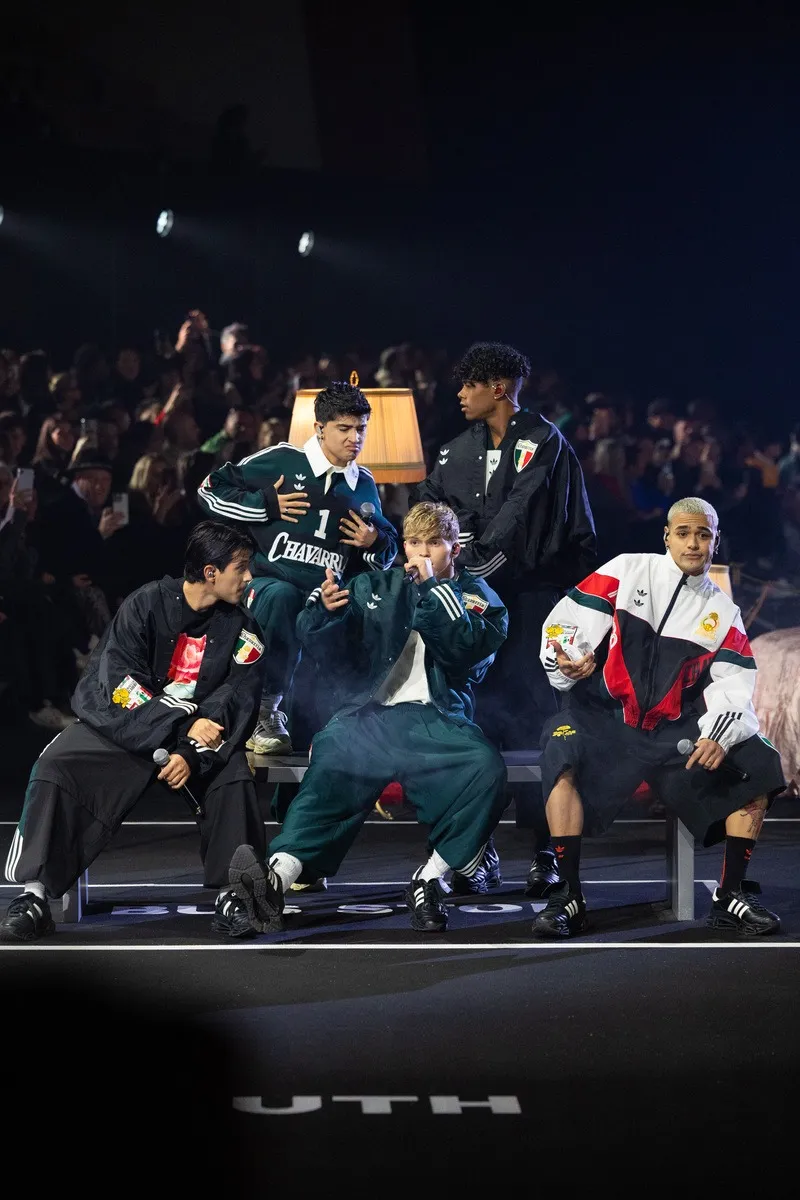

GA: Armani/Teatro has hosted designers for many seasons: Stella Jean and Andrea Pompilio, to name a few. Armani/Silos has hosted two film workshops with directors, screenwriters, and costume designers, meetings with key figures in photography, and collaborations with the architecture school and design school of the Politecnico di Milano.

CM: “A Jacket” was the title of a short film, the first project to emerge from Armani/Laboratorio, the cinema school dedicated to finding new talents in the industry. For each discipline, an artist served as a teacher—Michele Placido in direction, Luca Bigazzi in photography, Oscar-winner Gabriella Pescucci in costumes. The story of “A Jacket” refers to a well-tailored garment.

GA: Today, the creative platform you speak of must be dedicated to environmentally conscious generations; ethics must become part of the creative process.

CM: It has been announced that a Foundation will take care of perpetuating Mr. Armani’s legacy. Can we hope that Mr. Armani will help Milan become the most beautiful business city in Europe?

GA: Milan will shine, relying on the industrious spirit that has always characterized it. The city is rising, and I am here to give my contribution.

Carlo Mazzoni