The fiber of the Andes is Rough: an interview with Tomás Vera

Verdi: a family story and respect for Colombian natural raw materials – from fique fiber and copper wire, supporting the artisans of Curití Santander

Verdi and Roughness – The Family Story of Tomás Vera, Founder of the Brand

Verdi’s roots are in roughness. The constitutive element of an artisanal creation as well as the starting point for converting an elementary, bold, and rough material into something refined and adaptable to contemporary design. Verdi’s story began in 1995 with Carlos Vera Dieppa in the Colombian Andes. Vera Dieppa, the father of Tomás Vera, created rugs inspired by Japanese art, which are called tatami, using natural fibers. In his studio, Umari, named after a Colombian natural fiber, he used the same manufacturing technique employed to weave coffee sacks. This process was later transformed by his son into a starting point for founding Verdi, whose name was formed by combining the initials of his father’s last names.

“After this initial period,” Tomás Vera tells Lampoon, “my father created looms for weaving large rugs with geometric designs using the Adobe system. In 2000, he started using metallic fibers, a revolutionary idea that still defines the brand today. They were not just simple creations but my father’s creations, which made them very special to me. His studio closed in 2007, and three years later, my father died. When I was a child, I asked him what his dream was. He told me he wanted to develop a line of ultralight aircraft called Verdi. In 2010, my sister and I decided to work with him. The only thing left was a contact with a weaver. When I took over the business, I named it Verdi in his honor. From 2010 to 2014, I worked closely with designers and industry experts and learned a lot. In 2014, I founded the company Verdi: from an initial group of five people, we are now ninety.”

Verdi and Natural Raw Materials. Colombian Fique Produced in the Community of Curití Santander

Fique is one of the most used raw materials by Verdi. “It is a very resistant fiber and has an inherent shine. It is the same fiber that was used for coffee sacks, the first my father used to weave tatami with. Verdi supports eighteen families in the community of Curití Santander to help the artisans who extract and process the fiber. This ensures this art doesn’t get lost,” explains Vera.

All of Verdi’s natural fibers and raw materials are cultivated on Latin American soil. Before the spread of plastic packaging, fique fiber was used to weave bags for packaging coffee. The artisans of Curití have overcome the crisis by diversifying the use of fiber. Fique is a plant native to the Andes, whose characteristics are similar to hemp and sisal. It has spread to other South American countries thanks to its adaptability to environmental conditions. The production of fique fiber, known as cabuya, begins with the cultivation of the plant.

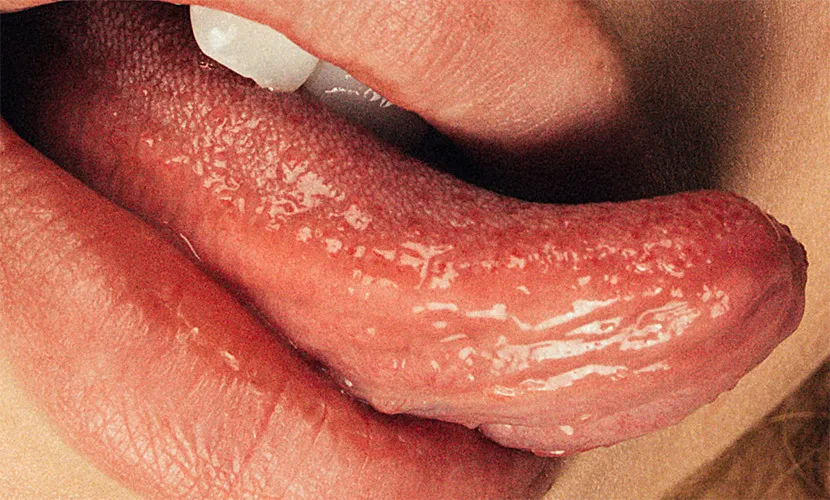

This plant has a rough and thick stem measuring about thirty centimeters in diameter and can reach up to seven meters in height. The stem produces several linear-lanceolate leaves arranged in a rosette. The rough fiber is extracted from the leaves, called pencas, which are cut by campesinos by hand. The machine used for fiber extraction (desfibrado) removes the outer layer of the leaf and the sap, called savia, keeping only the fibrous part. The fibers are then gathered into skeins and left to soak in large vats with water and soap for about fifteen hours to remove all sap residues. They are then rinsed and naturally dried. The fiber is often used maintaining rough consistency, and its natural color ranges from ivory to beige or hazelnut.

Verdi and Metallic Fibers – Pushing Manufacturing Beyond Standards to Make the Product More Resilient

Carlos Vera Dieppa had the idea of working with metallic fibers in 2010. “It was mainly a creative idea. I never had the chance to ask him why he did it. With the inclusion of metallic fibers, there is a combination between color palettes, between the luminous and matte finish. The light impacts the fabric depending on the time of day you look at the finished product. The metallic fiber reflects the light, attracting attention first, but what really matters is the design made with natural raw materials, a concept directly connected to the typical artisanal tradition of Latin America.”

Verdi uses Chile copper threads. Metals are resistant to raw materials. They do not oxidize, and add longevity to the finished product. Verdi’s vision is that metal with natural raw materials makes the product more durable over time.

Verdi – The Textile Manufacturing Process: From Tatami to Mochila, the Transition from Home Decor to Fashion

Colombia is the second country with the highest biodiversity in the world as it is crossed by the Amazon River. The vast catalog of fibers present in South America pushes Verdi to research how to incorporate them into their contemporary creations. Not just fique: among the brand’s favorite fibers the is cumare, extracted from a plant belonging to the palm family native to the Amazon, and baby alpaca from Peru.

Vera explained the main artisanal method of textile manufacturing to produce tatami: “The first phase is fiber procurement, called alistamiento, from which the design starts. For tatami weaving, we use a thicker fiber consistency and a multi-shaft loom with eighteen cylinders, inside which the weaver passes the thread according to the desired design. Some looms use the Adobe system, a kind of manual computer that functions like a small antique music box adorned with pins: in the music box, each pin plays a note while in the loom it indicates which shaft should be lifted. Consequently, the warp thread will go above or below it. This process creates a geometric figure. Introducing metal into these creations requires separate work in another part of our workshop. When the tatami design is finished, anti-slip properties are added, which increase its thickness. Finally, it is cut, and a border made of leather or natural fiber is assembled.”

When Verdi began producing the mochila, a reinterpretation of an ethnic backpack symbolic of South American culture, it was mainly a challenge and a clever use of the social media tool. It was an idea to create a unique product that had only the name and appearance of a mochila but was in fact realized with a crochet manufacturing technique by adding metallic fibers. “My father taught me that when you present a new idea to an artisan, it is likely that it will be rejected. If my father had not taught me what it means to persist and find a solution, I would have given up on the mochila. Only on the fourth attempt did we find a way to weave the bag.” To weave the mochila, Verdi uses only silk and banana fibers, which have a thin consistency. “The fibers for the mochila must be thin, similar to human hair diameter. Even the copper threads used for the geometric designs are very fine, and that is why it takes about fifteen days to handcraft a mochila. In the early periods of the release, the mochila did not sell because people did not understand the work behind it, which is a slow process. That is why it is not a scalable product.”

Tomas Verdi

Verdi is a Colombian textile studio born from Carlos Vera Dieppa’s artisanal heritage and Tomás Vera’s contemporary designs. Verdi’s textile manufacturing technique intertwines raw natural materials with metallic fibers, such as copper.

Martina Tondo