To prevent storage shelves full of leftovers, designers need to work backward by checking what fabric is available first and think about what will happen in the end

Circular Fashion: Moving towards Sustainability in the Textile Industry

Repairing, using and reusing products for as long as possible. In the textile industry, progress is being made in the development of new design strategies and business models by the cooperative arrangement Rekotex and research project Re:Textile in Borås, Sweden. The leading forum for sustainability in fashion, the Global Fashion Agenda (GFA), has developed a scenario in which circular business models should have a market share of at least 20 % of all sold garments globally for the industry to meet its targets according to The Paris Agreement on Climate Change. As of August 2020, the Circular Fashion System Commitment has been signed by 86 companies committed to taking action on textile circularity, representing 12.5% of the global fashion market.

Circular Fashion: The Role of Rekotex in Textile Sustainability

The GFA states that the steps towards circularity are achieved in collaboration with nongovernmental organizations, brands, and companies, with Scandinavia leading the way. Rekotex ensures that surplus fabrics from production do not end up as waste by reselling dead-stock at a discounted price. Rekotex is an ‘intermediary’, enabling partners to view the leftovers on others’ storage shelves and encouraging brands «to work in a resource-effective way, instead of producing new fabrics», explains founder Maria Jonsson. Jonsson’s database allows manufacturers to list unwanted fabric at the price they want, to be bought by other manufacturers.

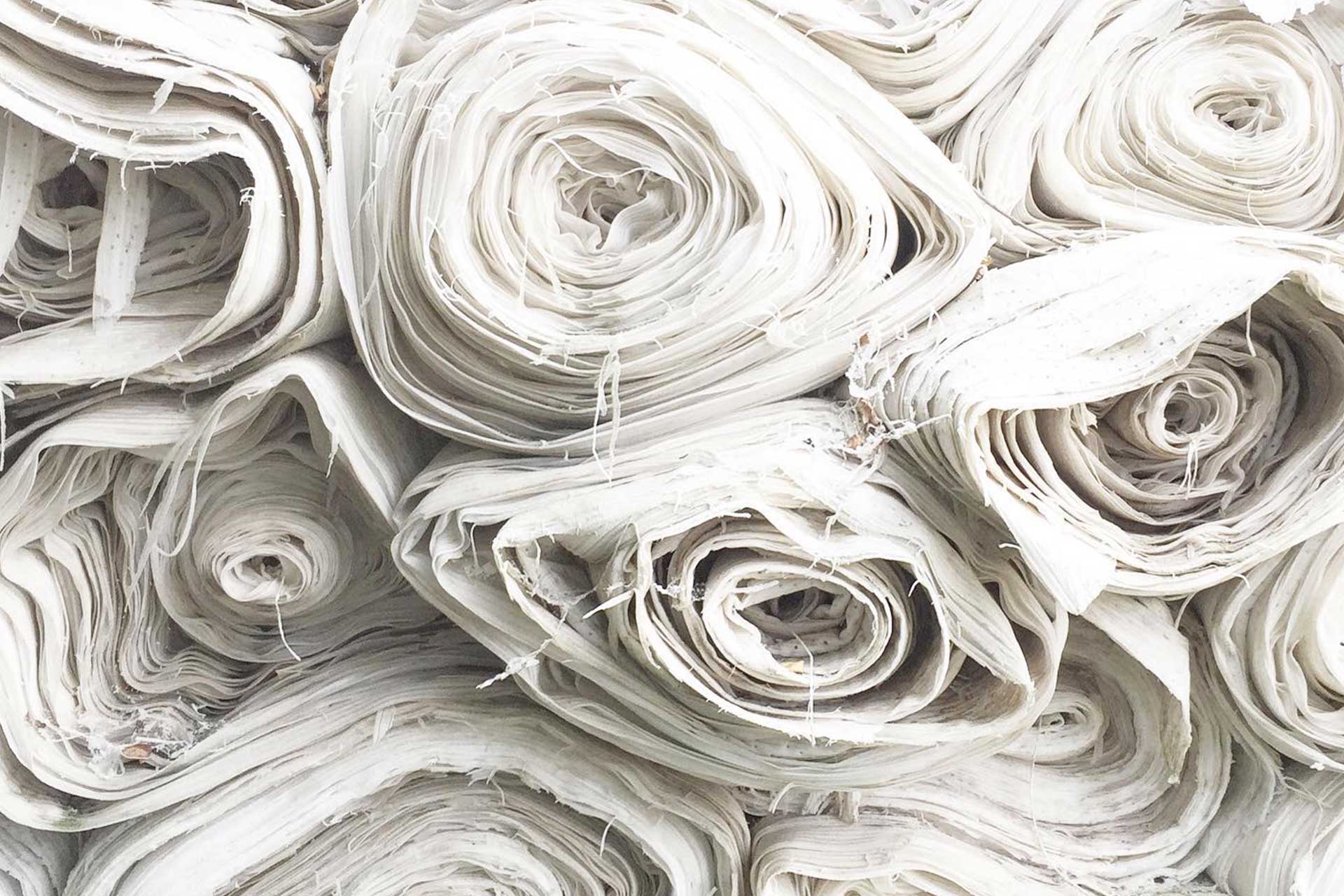

Rekotex takes care of the logistics, arranging the transport from the seller’s warehouse and the buyer’s production unit thus «the entire resource input required to make new fibers is avoided». It establishes circular flows in responsible textile care, «it’s a win-win situation: win for the seller, win for the buyer, and also the best thing for the environment», Jonsson adds. «If you see the textile process, it’s in the production of the fiber that the pollution on the environment is a problem. If you grow the fiber or if it is man-made, you need to use chemicals, you need to waste water and you need energy. Then these new rolls of fabric can be laying around and, in the worst case, they end up in a landfill». Through the Rekotex platform, 30,000 meters (or 18,000kg) of fabrics have been put to use.

Rekotex and Re:textile: Collaborating for a Circular Fashion Industry

Based on cotton fabrics alone, in which approximate resources used for 1kg cotton fabric is 1kg chemicals and 10,000 liters of water, Rekotex has prevented the use of 18,000kg of chemicals and enough water to cover the consumption of 3,600 people for a year. Rekotex works together with around 30 selling companies, Swedish signatories of the 2020 Circular Fashion System Commitment such as Nudie Jeans and Filippa K, and other European brands. The buyers of Rekotex tend to be «smaller actors but also include bigger brands with high ambitions to work sustainable». Jonsson acknowledges the challenges faced by big brands used to working as there’s more to do and more to risk in changing their business model.

«If a minimum buy is 5000 meters but you know that you’re just going to use 3000, you need to think if this is right if you should start this production», this way you do not have leftovers piled on storage shelves. Rekotex encourages designers to work backward by checking what fabric is available first and, through all stages, «to think what will happen in the end». Re:textile is a project within Science Park Borås that focuses on innovating design principles, business models, and production systems that enable circular flows in the textile and fashion industry. «It is a big subject that needs to be seen on a systemic level», clarifies Project Manager Adrian Zethraeus.

Rekotex and Re:Textile Leading the Way in Sustainable Textile Industry

The project seeks to create models for fashion companies centered on «prolonging active lifetime» and the use of garments, through resell, rental, or product life extension services. In line with the fundamentals of Rekotex, the premise of Re:Textile «is to consider the entire life-cycle of the product». It all starts with the design. Dependent on the type of garment, end-user, and required function of the garment, design strategies can be used to optimize the product’s circular potential.

For the majority of garments, the longevity and reuse possibilities are the preferred circular options, with the possibility to recycle the material when the garment is worn out. The lifetime of the garment can be extended through repairs or updates to make the garment «functional or fashionable for a longer period». These remaking processes can include re-dying, printing, reshaping, or additional design elements promoting the closing and slowing of resource loops. The potential of remaking depends on the initial design and it is possible that designing for longevity can hinder later material recycling. Zethraeus explained that designers «have to choose what kind of circular scenario is optimal for the specific garment».

Re:Design and Re:Textile: Circular Concepts and Infrastructure in Sweden’s Textile Industry

Re:Design runs alongside Re:Textile, helping companies to develop pilot-concepts, with workshops akin to a Research & Development department. «We facilitate the processes and help companies brainstorm ideas to find circular opportunities», says Zethraeus. Employing designer experts, business developers, and technicians, as well as providing access to machine facilities for prototyping and testing, Re:Design has achieved successes. With workwear brand Hejco they have developed a rental and take-back system now implemented in their business model. Fashion retailer MQ has launched a resell concept in some of their shopping locations and the retailer Lindex has continued working with the remake of dead-stock items. These business models require infrastructure for local production in terms of sorting, cleaning, refurbishment, and remake processes. Since 2015, Re:Textile has been involved in external funded specialized projects, examining the economic and practical feasibility of the circular design and the feasibility for a national sorting center for textiles in Sweden.

Critical Success Factors and Collaboration Key to Achieving Circularity in Sweden’s Textile Industry

From these case studies, they have defined the critical success factors for circularity decision-making: high-quality material input, material and process costs, quality of output, streamlined lead times, with reverse flow and redesign flexibility, market acceptance, guidelines and legislations, and collaboration with stakeholders. The enforcement of standards, guidelines and legislations by the industry and policymakers, the GFA and the UN, assist the adoption of redesign activities that move towards circularity. As both Jonsson and Zethraeus agree, collaboration and coordination are crucial for systemic change and innovation. Clarity and knowledge-sharing can be facilitated by geographic proximity and lead times can be reduced by focusing on local production. Marie Jonsson sees the success «lying in smaller brands working on a smaller scale» as sewing units are increasing across Sweden. Zethraeus cites «the big challenge will be for the large actors to transform towards circularity in a way that will keep the profits intact, while not being outshined by new disruptors in the industry».

Achieving Circularity in Sweden’s Textile Industry, According to Re:Textile Project

There are bigger brands that want to produce locally, in a close market with Rekotex, resolves Jonsson. As we’ve seen in recent years, the market has changed. If the entire life cycle of a product is to be considered in the design process, the end consumer needs to be a collaborative partner that fully understands the value of redesigned fashion. Through transparency and communication, consumer behavior can change and this can create positive incentives for the rest of the industry.

«Traditionally the textile business has been closed, you have your secrets that you don’t tell them. Cooperation is the key for a more circular way of taking care of resources» finishes Marie. As a public-funded project as part of the University of Borås, Re:Textile has to be «a neutral and transparent actor to the benefit of the entire industry» with their findings open for everyone to use. The future of the textile and fashion industry lays within the ongoing research of projects like Re:Textile that addresses the action points set out in the 2020 Circular Fashion System Commitment. Adrian Zethraeus hopes that a circular transition will lead to new business opportunities, stimulate job creation and positive social effects, beyond Scandinavia. Right now, industry members, consumers and policymakers need to prioritize capturing the full value of already-existing fibers and clothing so that the textile sector moves a step closer to circularity.

Marie Jonsson

Marie Jonsson studied at The Swedish School of Textiles and founded Rekotex in 2017. After witnessing the problems with waste in industry, Rekotex was developed as a cooperative arrangement that enables the buying or selling of leftover fabrics from textile manufacturers production. The database allows buyers to obtain high quality textiles in smaller quantities than normally offered by fabric producers and invites brands to contribute to sustainability in the textile industry.

Adrian Zethraeus

Adrian Zethraeus is the Project Manager of Re:Textile, concerned with resource efficiency in the textile industry. He is responsible for the project’s goals and budget. Re:textile is a research project within Smart Textiles at Science Park Borås. Re:textile develops new design principles, business models and production systems that make circular flows in the textile industry possible.